A device for connecting inner liner and outer coat of fire hose

A fire hose and inner lining technology, which is applied in the field of equipment connecting the inner lining and outer jacket of the fire hose, can solve the problems of increased labor costs, time and energy consumption, hose damage, etc., and achieve the effect of labor saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

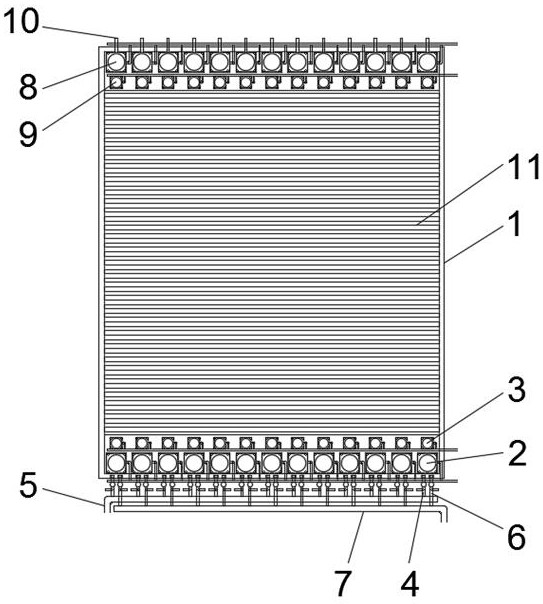

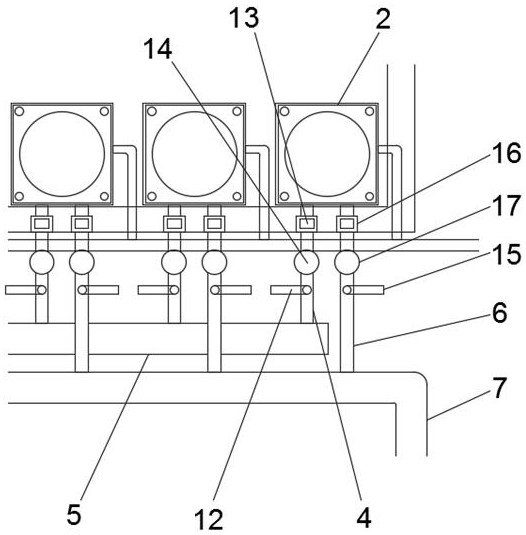

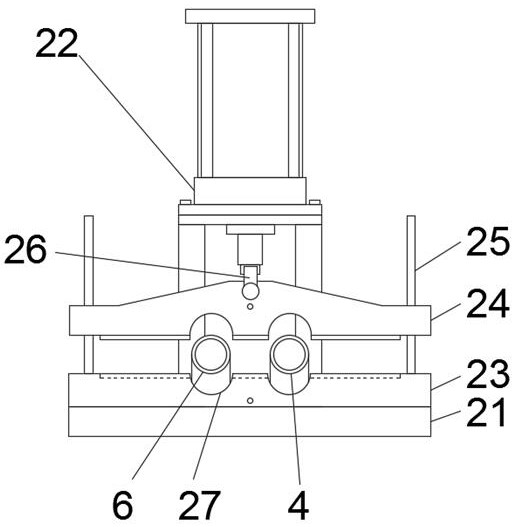

[0027] See Figure 1-2 The present invention provides a technical solution: an apparatus for fire a water belt liner and jacket, including a countertop 1, a clamp mechanism A2, a slit mechanism A3, a steam branch 4, a steam tube 5, a cold air branch 6, a cold air The total pipe 7, the clamp mechanism B8, the incision mechanism B9, the exhaust pipe 10 and the crossbar 11 are provided with several clamp mechanisms A2 and several cutting mechanisms A3, and the clamp mechanism A2 corresponds to the incision mechanism A3, each Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com