An automatic gluing machine

A gluing machine, automatic technology, applied in the direction of lamination device, sending objects, lamination, etc., to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

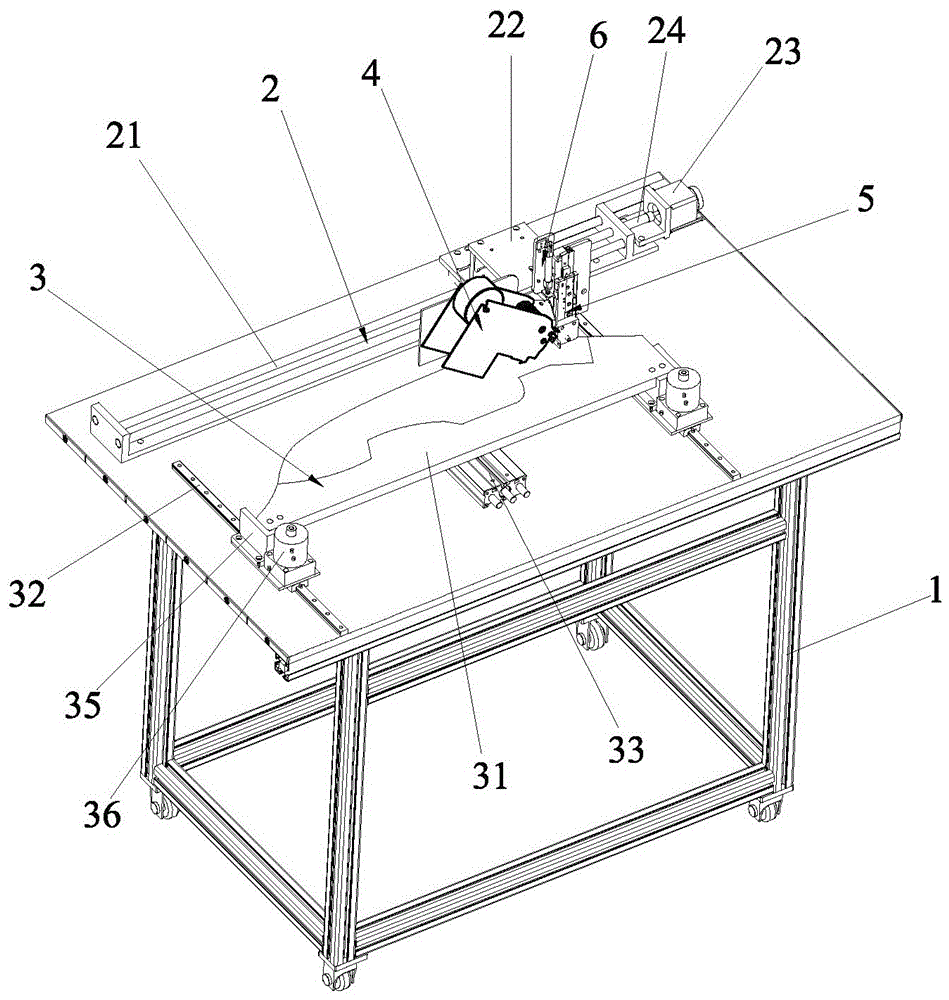

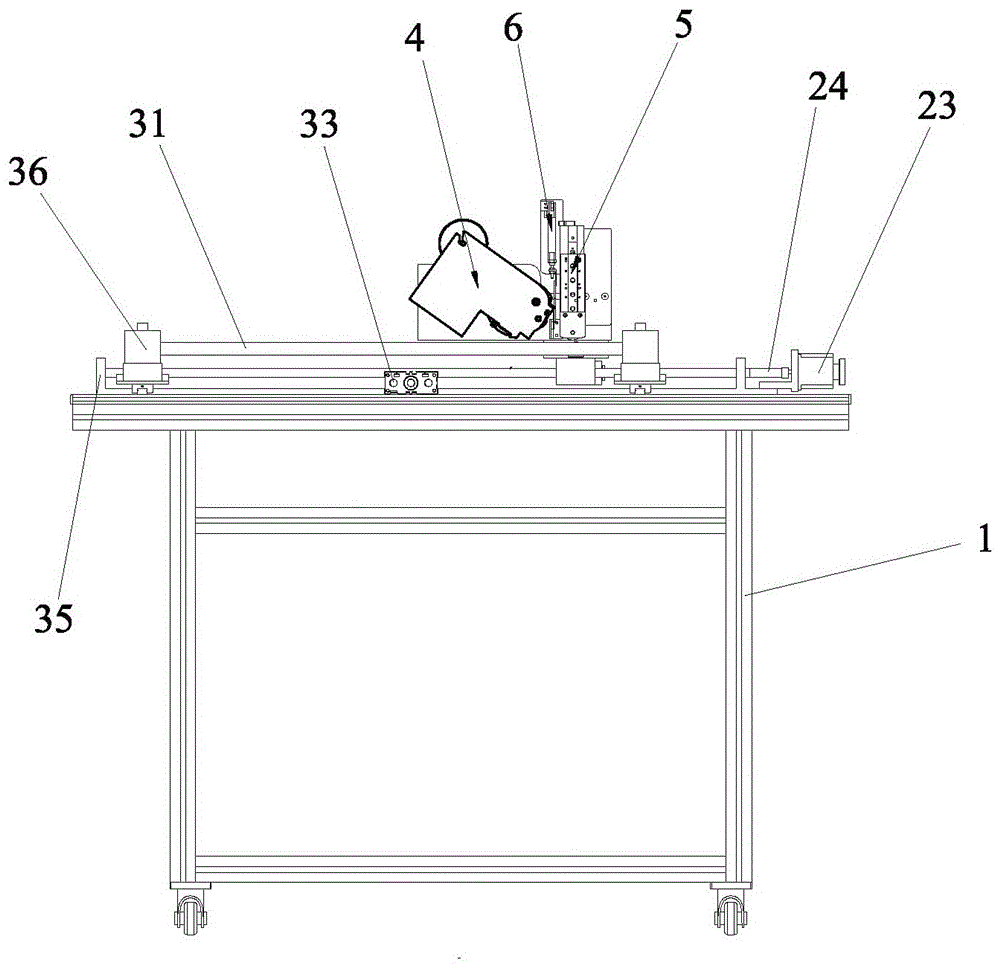

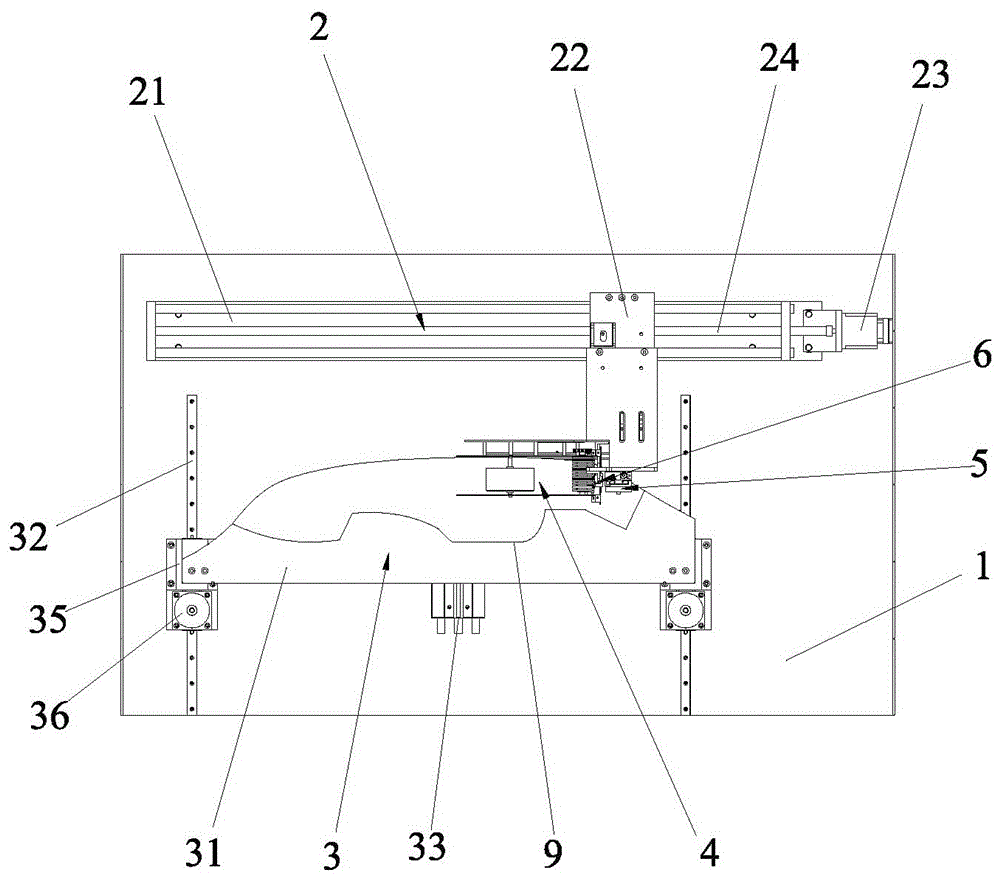

[0031] What the present invention discloses is a kind of automatic glue sticking machine, is used for sticking adhesive tape on the suture place of leather goods, such as Figure 1 to Figure 4 Shown is a preferred embodiment of the present invention. Described gluing machine comprises frame 1, is installed with sliding mechanism 2, profiling mechanism 3, gluing mechanism 4, pressing mechanism 5, glue cutting mechanism 6 and PLC control mechanism (not shown in the figure) on frame 1 Shows). in:

[0032] The sliding mechanism 2 includes a sliding rail 21 installed on the frame 1 , a connecting frame 22 installed on the sliding rail 21 and a driving mechanism capable of driving the connecting frame 22 to move on the sliding rail 21 . The driving mechanism can adopt various structures. In this embodiment, the driving mechanism is a scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com