Feed stirring device with differential rotation mechanism

A rotating mechanism and feed mixing technology, which is applied to mixers with rotating agitating devices, feed, mixer accessories, etc., can solve the problems of shortening the residence time of feed, reducing digestibility, waste, etc., and achieve improved material mixing effect and good mixing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

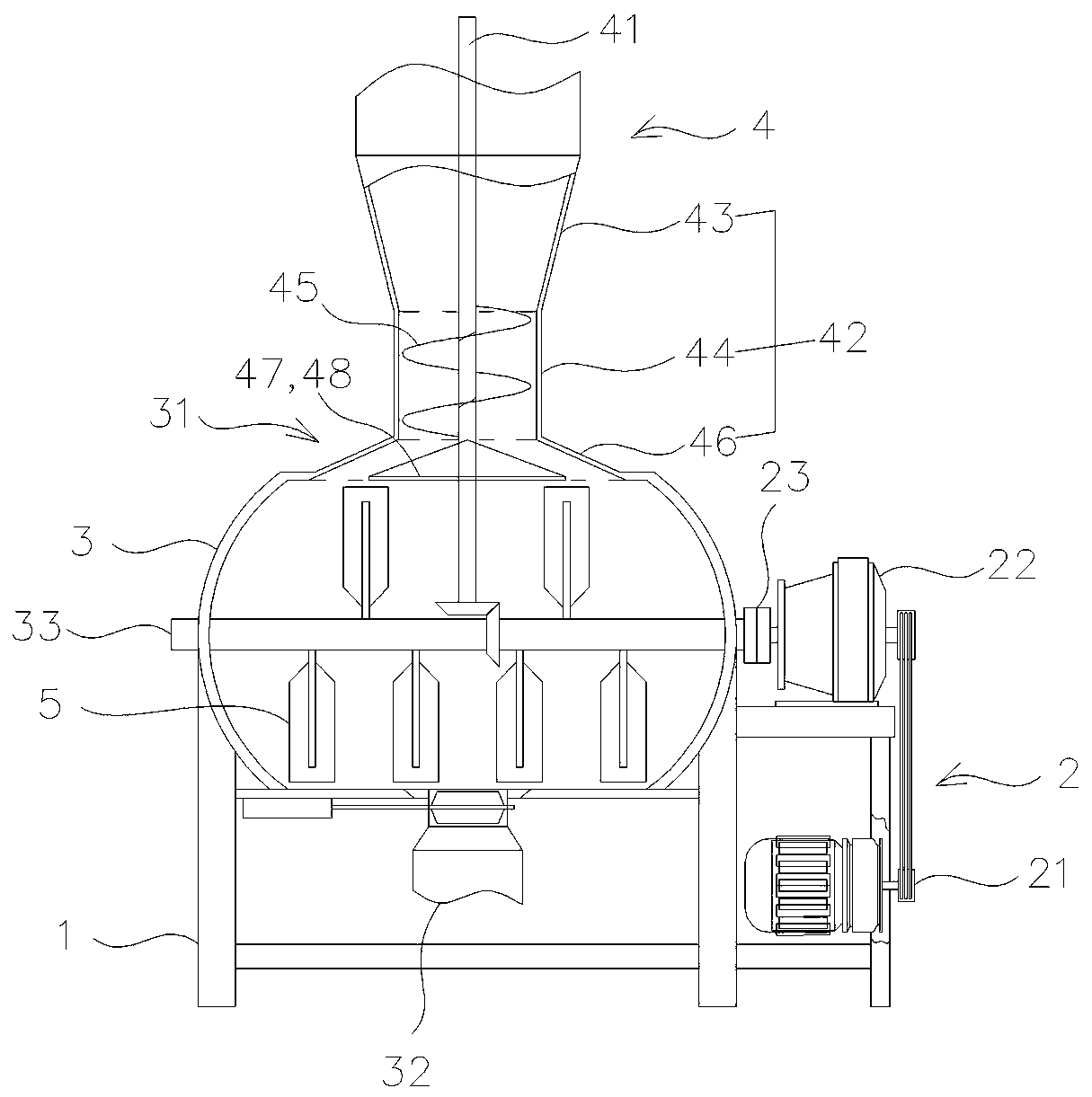

[0056] Such as figure 1 As shown, a feed mixing device with a differential rotation mechanism, the mixing device includes a frame, a barrel, a power unit, the frame is used to support, fix, connect the barrel, and the power unit, and the barrel is used for mixing, Stirring materials, the power unit is used to provide driving force to the barrel;

[0057] The barrel is cylindrical and placed horizontally, with a feed port above the barrel and a discharge port below, and a stirring shaft inside the barrel;

[0058] The stirring shaft is connected to the power unit through transmission;

[0059] The power device includes but is not limited to a motor and a reducer. The motor and the reducer are connected in a transmission manner including but not limited to a belt, a chain, and a connecting rod. A coupling is used between the reducer and the stirring shaft. phase drive connection;

[0060] It is characterized by:

[0061] The feeding port is provided with a feeding control de...

Embodiment 2

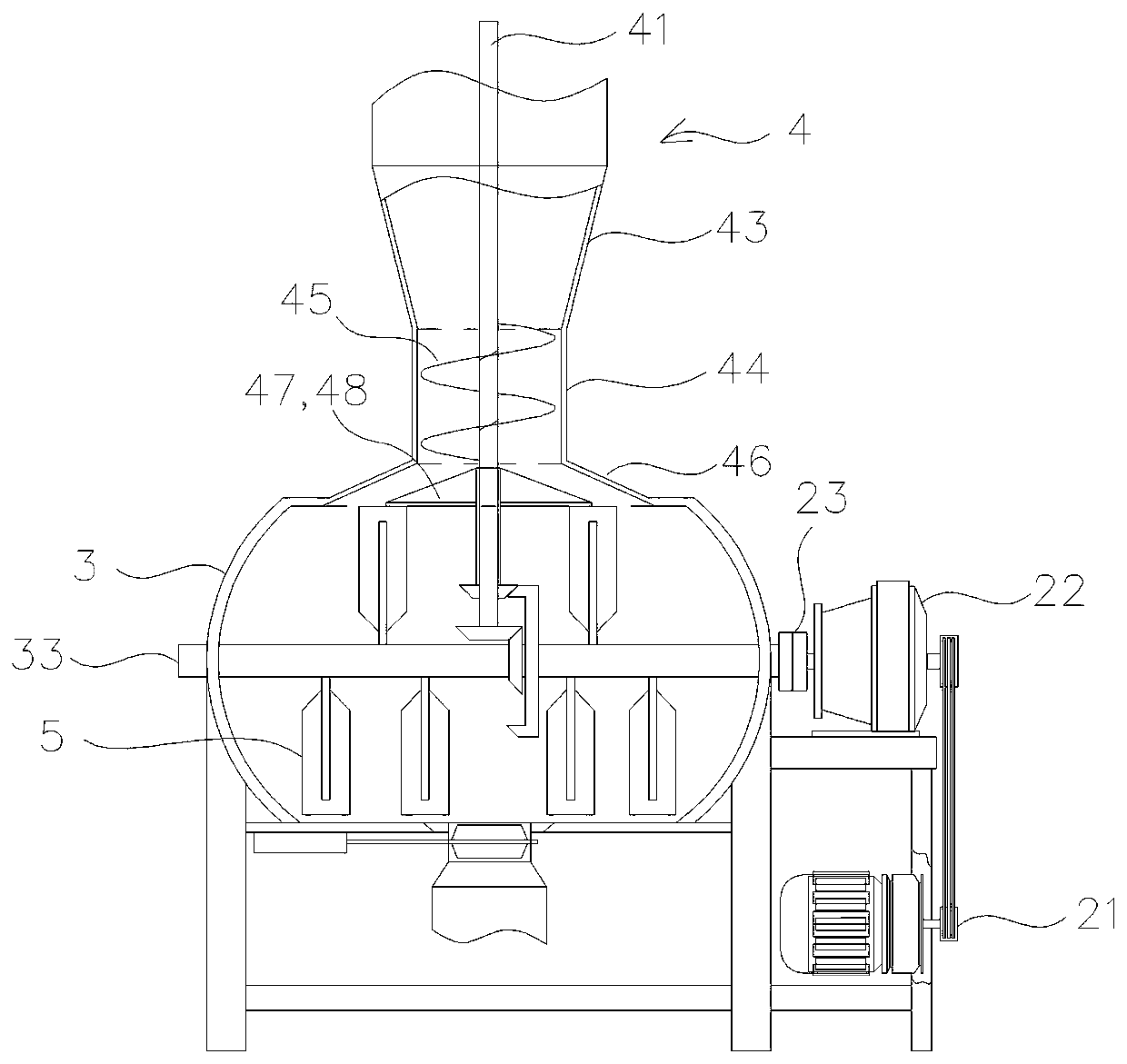

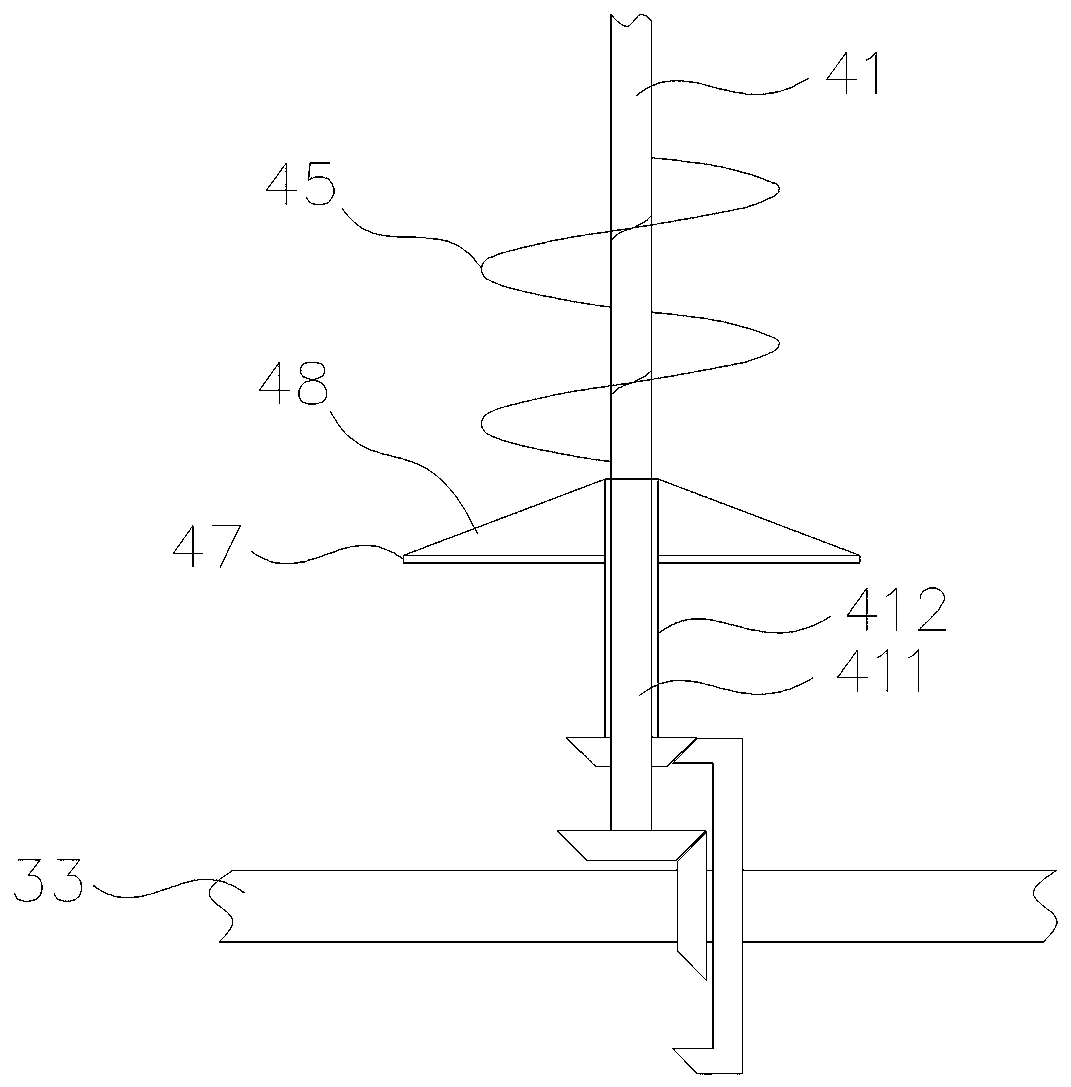

[0076] Such as figure 2 , 3 As shown, on the basis of the above-mentioned embodiments, the feed shaft described in this embodiment includes a feed inner shaft and a feed outer shaft, and the feed outer shaft is sleeved outside the feed inner shaft; the auger or a similar structure The device is fixedly installed on the inner shaft of the feeding material, and the flying disc and the baffle are fixedly installed on the outer shaft of the feeding material.

[0077] The feeding inner shaft and the feeding outer shaft are respectively connected to the stirring shaft through bevel gears.

[0078] Coaxial nesting or similar methods are used to implement differential speed processing on the control bin and diffusion bin of the feed control device, that is, the auger in the control bin and the flying disc in the diffusion bin run at different speeds to Make the material conveying and material throwing operation speed match reasonably and efficiently. It is best that the material th...

Embodiment 3

[0080] Such as Figure 4 As shown, on the basis of the above-mentioned embodiments, an inner cage is provided in the material cylinder described in this embodiment, and the inner cage is cylindrical and has a gap with the inner wall of the circumferential surface of the material cylinder;

[0081] The two end faces of the inner cage are provided with supporting parts, which are assembled and connected with the end faces of the barrel through bearings, and the supporting parts protrude outwards and protrude from the end faces of the barrel, and the supporting parts include but are not limited to Any way of belt, chain and gear is connected with the power device;

[0082] The inner wall of the inner cage is provided with a plurality of scrapers arranged in dislocation with the scrapers on the stirring shaft.

[0083] As for the assembly structure and auxiliary structure between the inner cage and the barrel, they belong to conventional technical solutions and will not be repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com