Crystallized glass

一种结晶化玻璃、氧化物的技术,应用在结晶化玻璃领域,能够解决可见光透射性差、无法获得压缩应力值等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~29

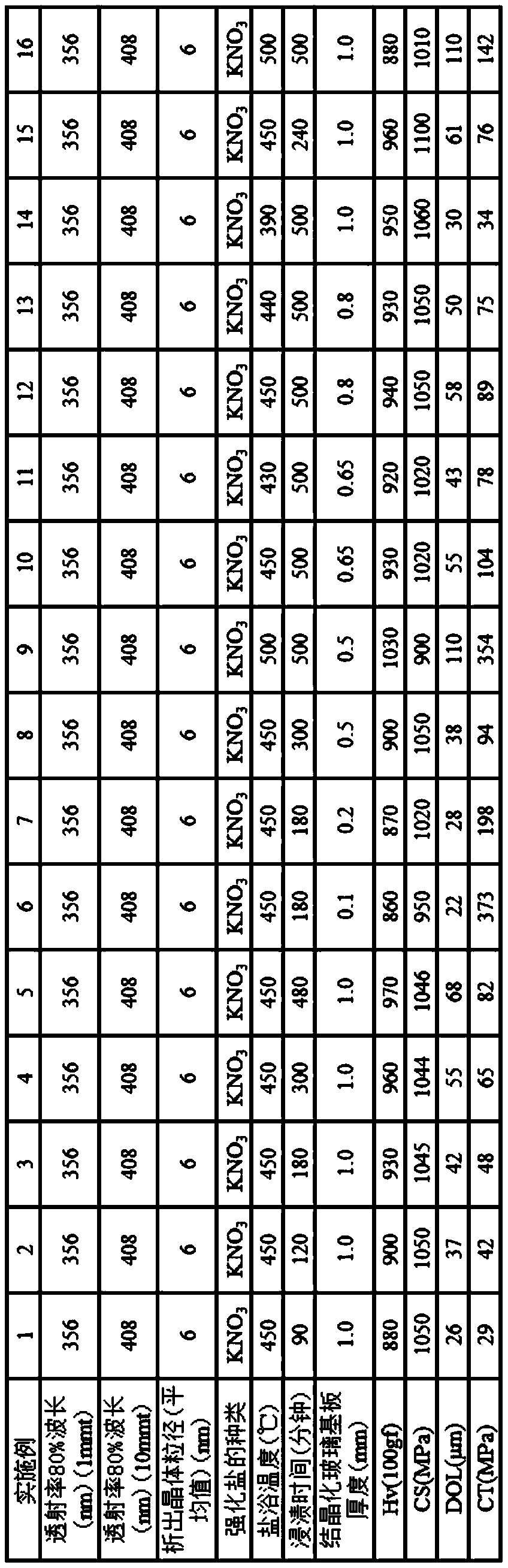

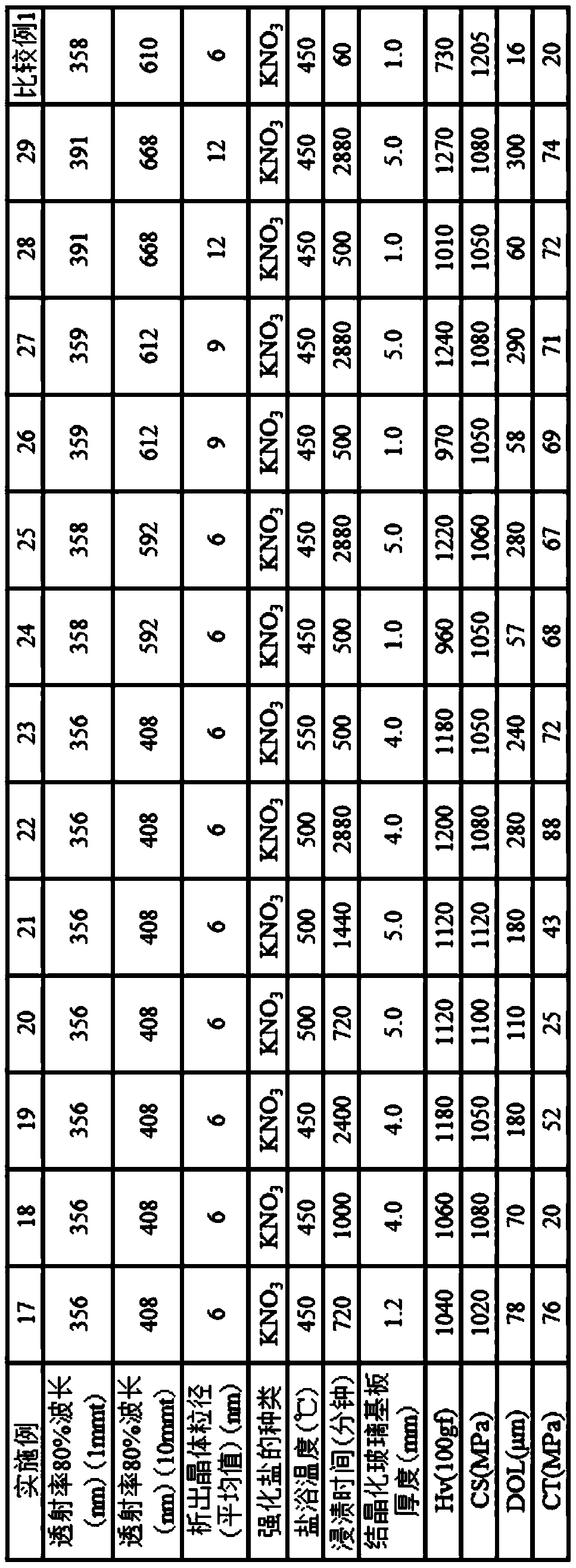

[0116] (Examples 1 to 29, Comparative Example 1)

[0117] As raw materials for each component of crystallized glass, the corresponding oxides, hydroxides, carbonates, nitrates, fluorides, metaphosphoric acid compounds and other raw materials are selected, and then weighed in such a way that the following composition ratios are obtained. These ingredients are mixed well and evenly.

[0118] (% by weight in terms of oxides)

[0119] SiO 2 Composition is 55%, Al 2 o 3 The composition is 18%, Na 2 O composition is 12%, K 2 O composition is 2%, MgO composition is 8%, CaO composition is 1%, TiO 2 Composition is 5%, Sb 2 o 3 The composition is 0.1%.

[0120] Next, the mixed raw materials are put into a platinum crucible and melted. Thereafter, the melted glass is stirred to homogenize it, cast into a mold, etc., and cooled slowly to produce raw glass.

[0121] For nucleation and crystallization, the obtained original glass is subjected to a one-stage heat treatment to prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com