Method and device for controlling expansion and contraction of printed circuit board

A printed circuit board, control technology, applied in the direction of printed circuit, printed circuit manufacturing, computer design circuit, etc., can solve problems such as error-prone, affecting efficiency, complex expansion and contraction process, etc., to improve product quality and production efficiency, and not easy to make mistakes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

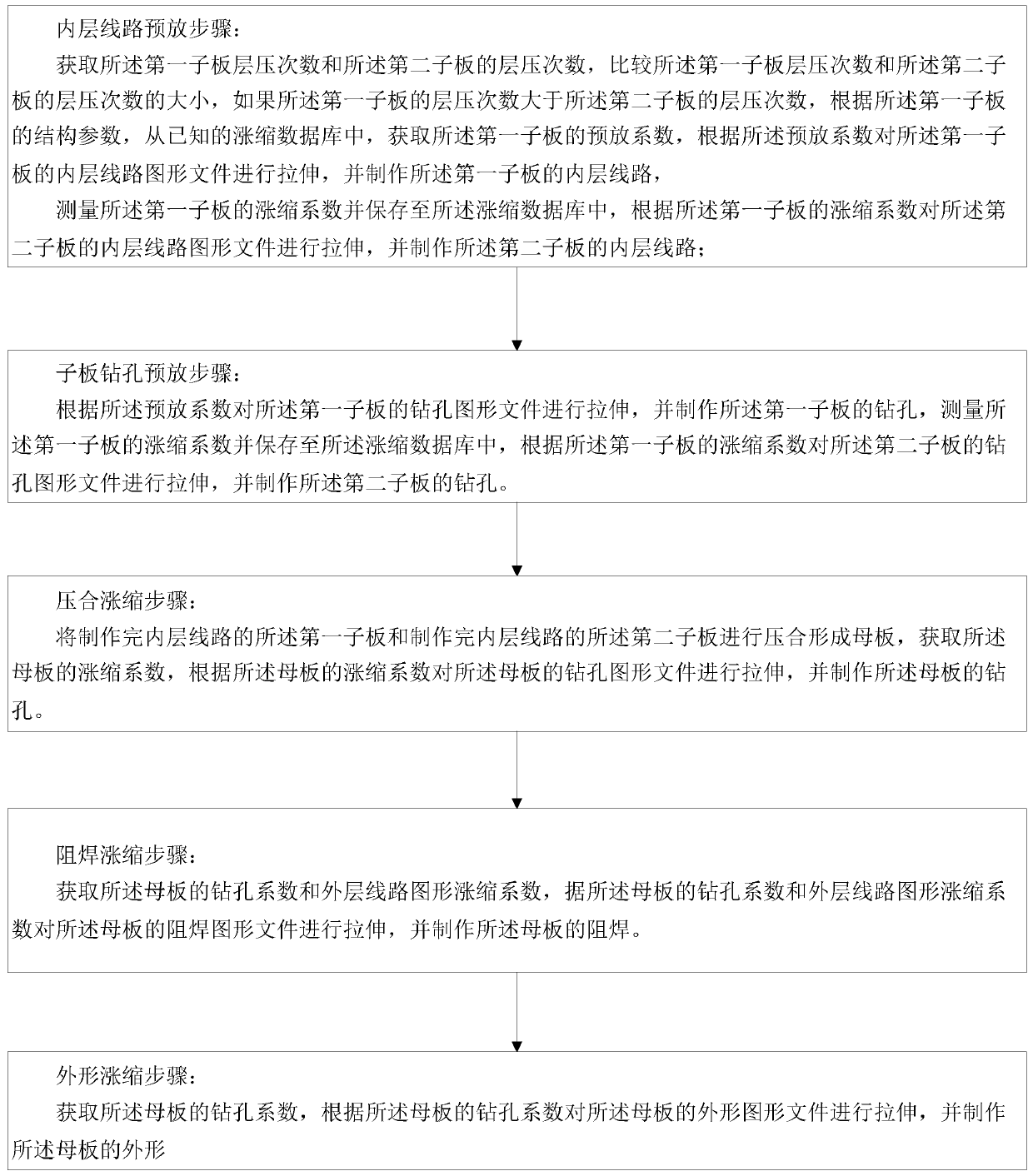

Method used

Image

Examples

Embodiment 1

[0050] In this embodiment, the model of the printed circuit board for expansion and contraction control is 6V29U2DHA0.

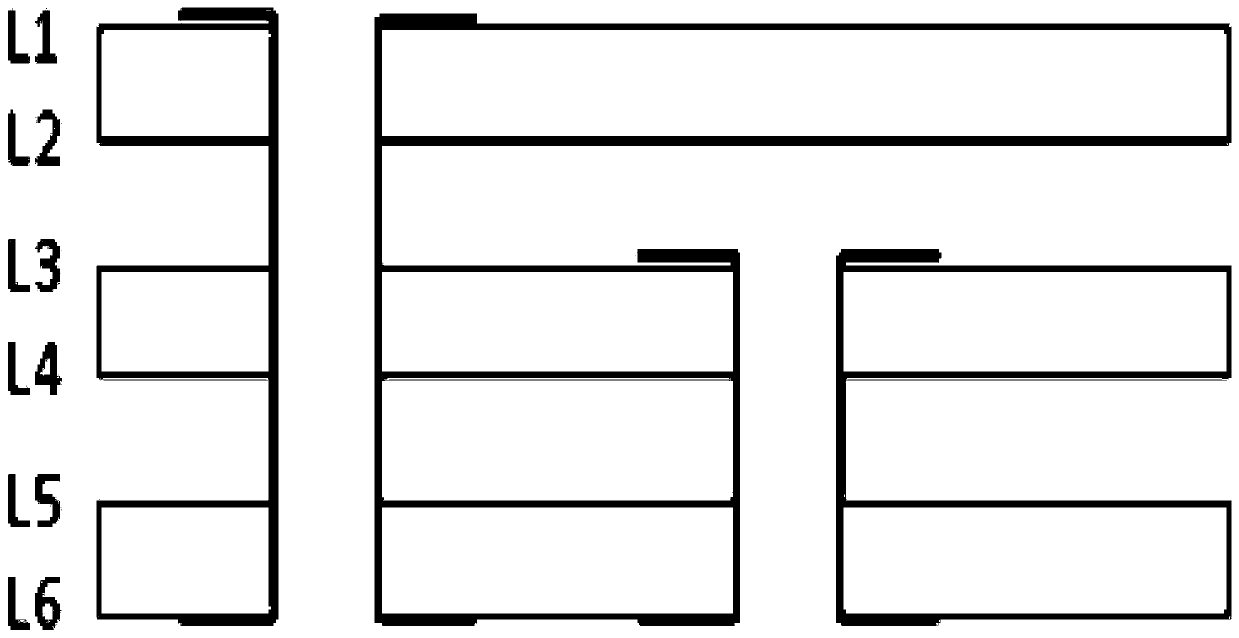

[0051] Such as image 3As shown, the model of the printed circuit board is 6V29U2DHA0 including the first sub-board (L1-L2) and the second sub-board (L3-L6), wherein the second sub-board (L3-L6) consists of the first core board and the second sub-board It consists of two core boards, the model of which is 4V29UJ0VA0, the models of the first core board and the second core board are both 2V29UVNMA0, and the first sub-board is composed of the core board 2V29UVNMA0.

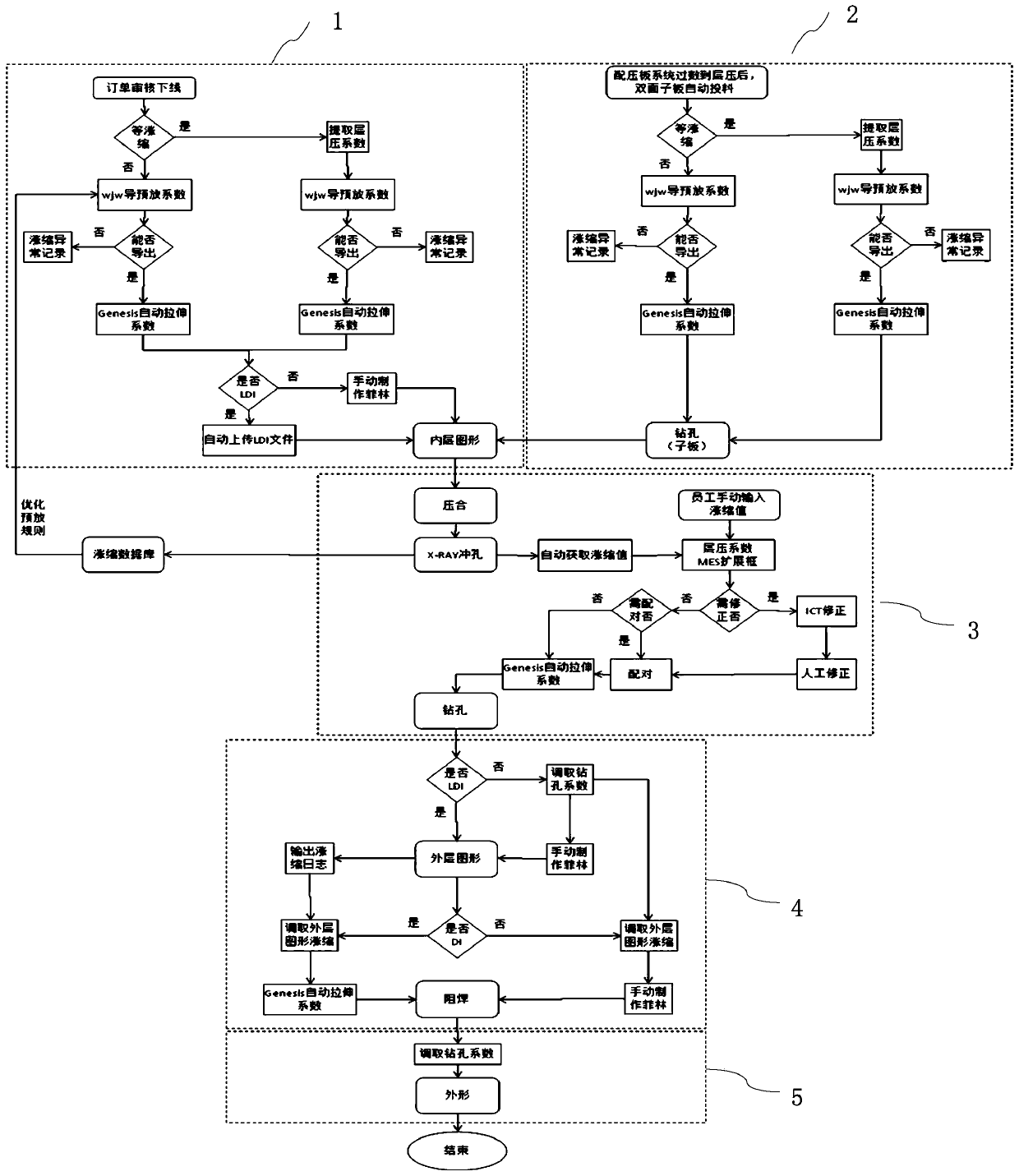

[0052] refer to figure 2 , which shows a flow chart of printed circuit board expansion and contraction control, the specific process is as follows

[0053] Since the number of laminations of the second sub-board (L3-L6) is 2 greater than that of the first sub-board (L1-L2), the second sub-board (L3-L6) is preferentially made, according to the structural parameters of the first sub-board ( One o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com