Magnesium battery electrolyte, preparation method of magnesium battery electrolyte, and magnesium battery

A magnesium battery and electrolyte technology, applied in the energy field, can solve the problems of poor stability, magnesium-aluminum co-deposition, expensive boron salt, etc., and achieve the effect of strong performance and improved battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

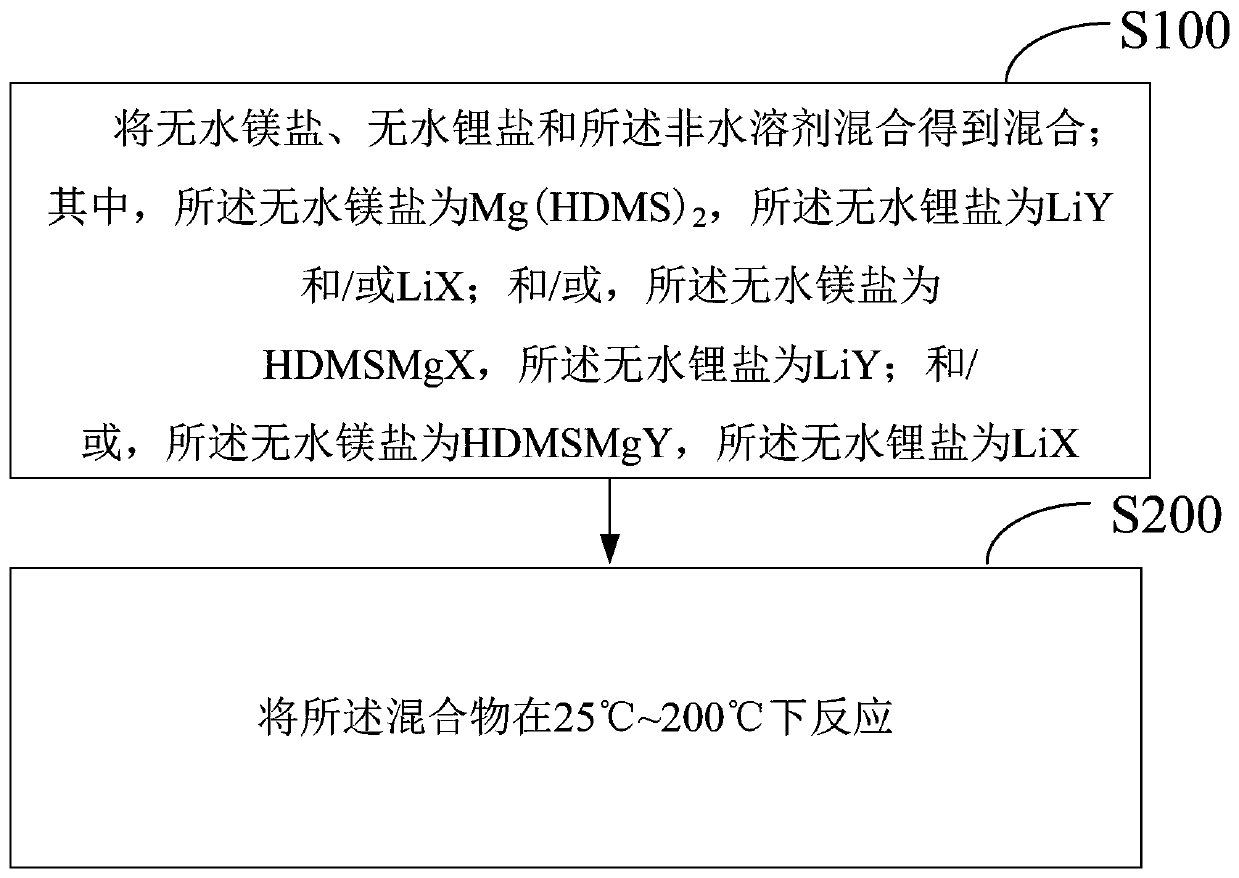

[0048] see figure 1 , the embodiment of the present invention also provides a preparation method of the magnesium battery electrolyte, comprising:

[0049] S100, mixing anhydrous magnesium salt, anhydrous lithium salt and the non-aqueous solvent to obtain a mixture; and

[0050] S200, reacting the mixture at 25°C to 200°C;

[0051] Wherein, the anhydrous magnesium salt is Mg(HDMS) 2 , the anhydrous lithium salt is LiY and / or LiX.

[0052] Lithium salts are generally considered as ordinary salts, which do not have acidity or alkalinity. After a lot of experiments, the present invention creatively uses organic magnesium salts as Lewis bases and inorganic lithium salts as Lewis acids to prepare the magnesium battery electrolyte, the Lewis acids can absorb electrons, the Lewis bases donate electrons, and the Lewis acids and the Lewis base under the action of a complexing agent to obtain a coordinated anion and a coordinated cation respectively, thereby forming a stable electro...

Embodiment

[0061] Preparation of magnesium battery electrolyte: (the red part below is modified according to the actual experiment)

[0062] 1035.12 mg of anhydrous Mg(HMDS) 2 and 254.34mg of anhydrous lithium chloride (LiCl) (anhydrous Mg (HMDS) 2 and anhydrous lithium chloride at a molar ratio of 1:2) were mixed in 10 mL of tetrahydrofuran (THF), and reacted at 25° C. for 24 h to obtain a magnesium battery electrolyte. The electrolyte was subjected to nuclear magnetic analysis and Raman spectral analysis.

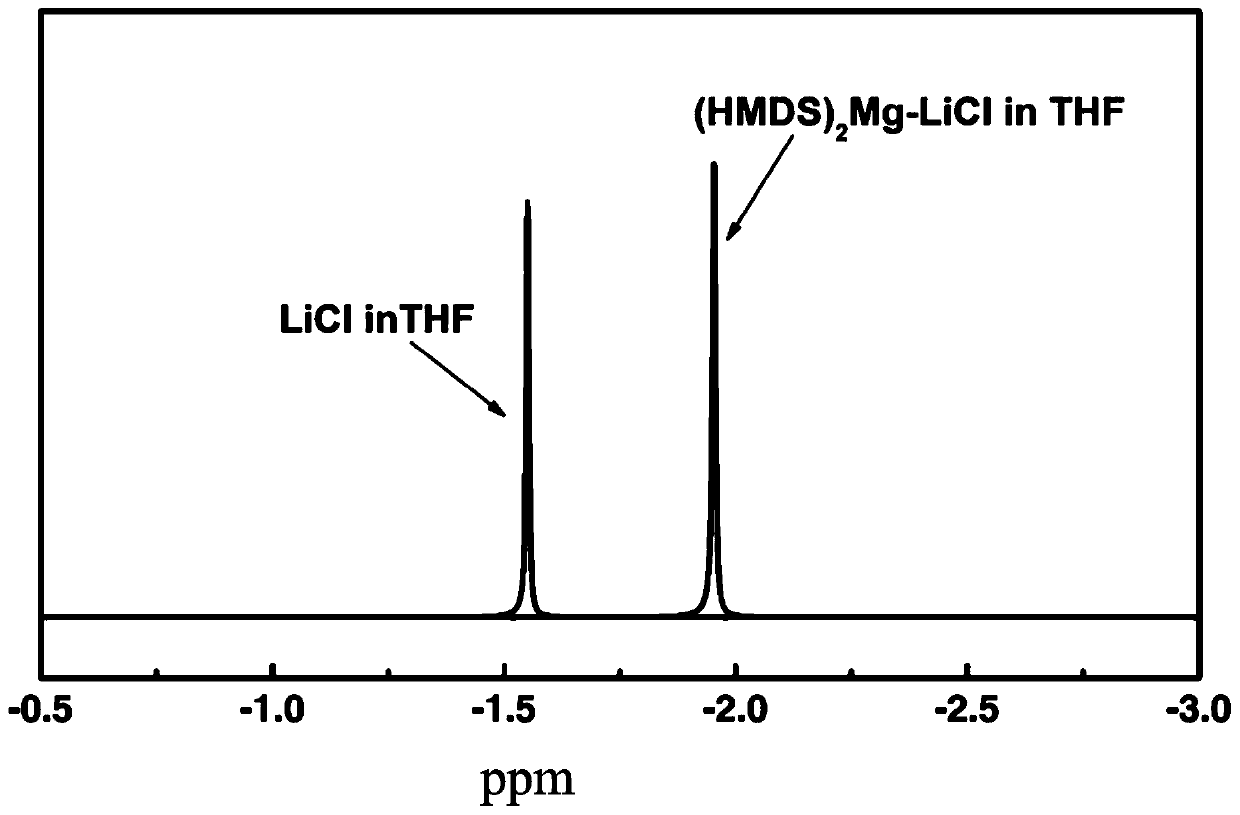

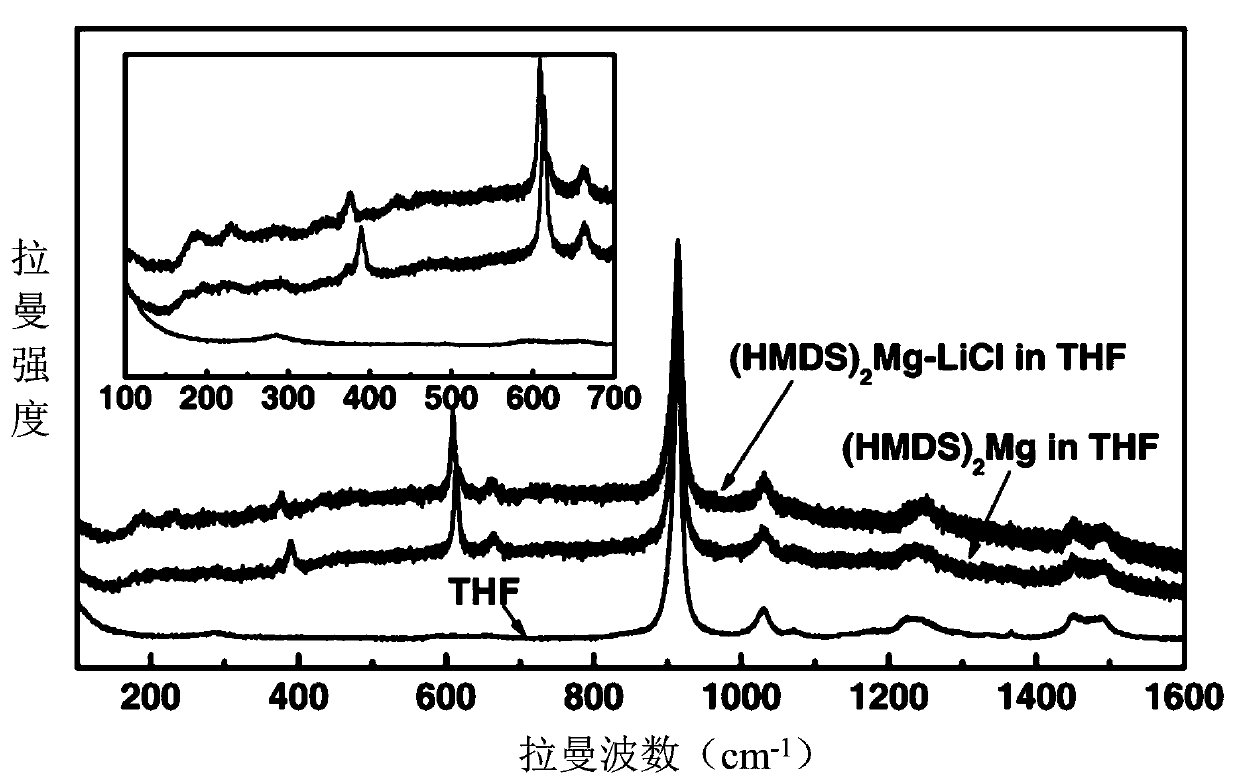

[0063] see figure 2 and image 3 As shown, the NMR analysis results show that after adding Mg(HMDS) 2 After that, the coordination environment of LiCl changed significantly, that is, the anhydrous MgCl 2 A chemical reaction with anhydrous LiCl occurred in THF, and the chemical shift shifted by 0.3ppm, proving that [HMDSLiCl] - generation. The results of Raman spectroscopy analysis show that at 242cm -1 [Mg 2 Cl 3 ] + characteristic peaks. Combined with NMR and Raman dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com