Industrial rubber compound Mooney viscosity soft measurement method based on integrated immediate learning

A rubber Mooney and soft measurement technology, applied in the direction of integrated learning, instrumentation, calculation, etc., can solve problems such as Mooney viscosity is difficult to detect online, and achieve the effect of improving prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

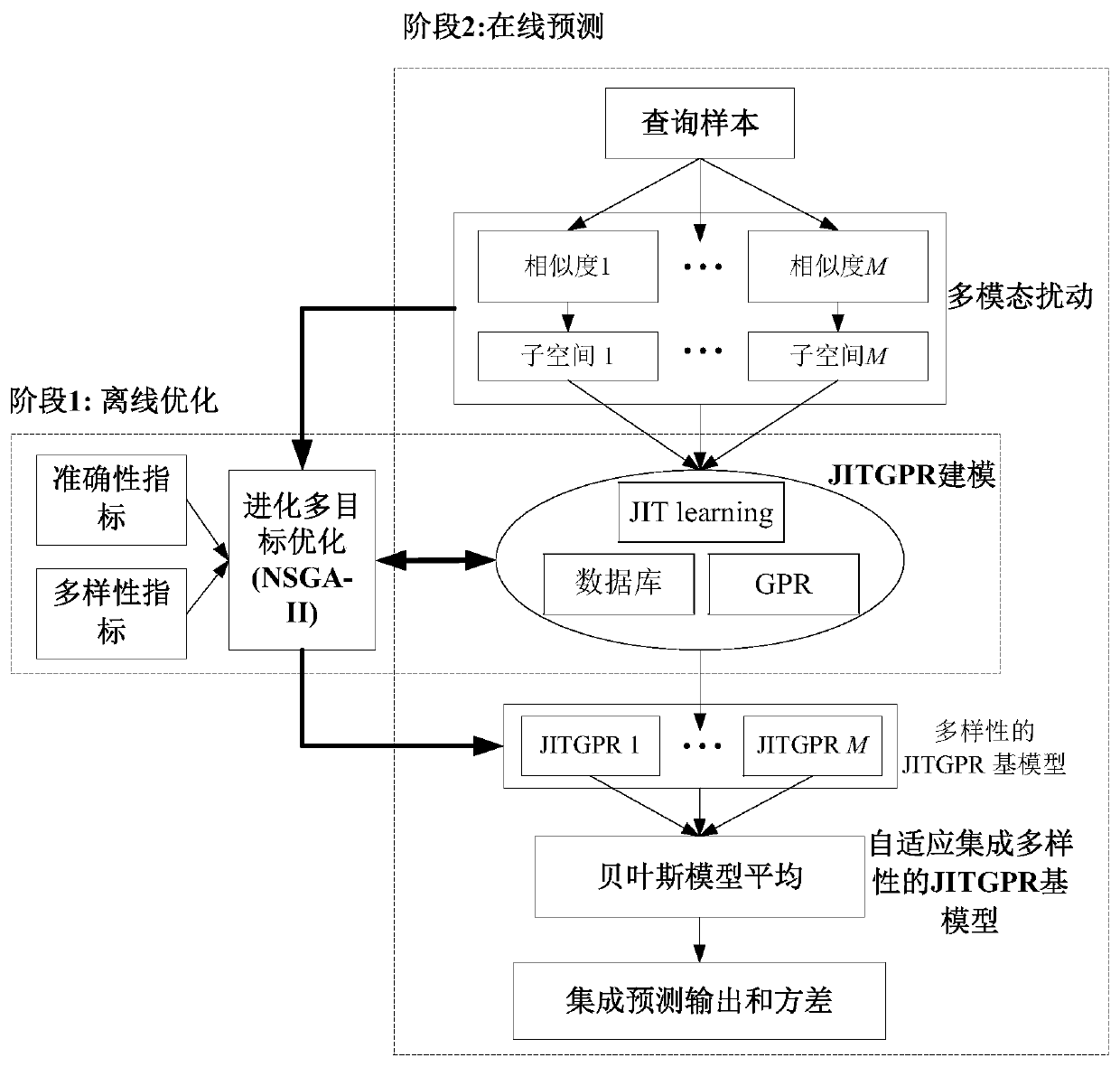

Method used

Image

Examples

Embodiment 2

[0073] Example 2: The validity and accuracy of the MP-EJITGPR method for predicting Mooney viscosity are illustrated below in conjunction with a specific industrial rubber mixing process example of a tire manufacturer in East China. The production process of industrial rubber mixing is a typical multi-period, non-linear batch process. Various compounding agents are added to the raw meal according to the technical formula, and complex chemical reactions are carried out in the mixer to prepare synthetic rubber. The whole process is controlled by PLC. The controller completes the control of the rubber compound production process. In the reaction process, Mooney viscosity is a very important key indicator. In order to control product quality and production efficiency, Mooney viscosity is predicted online by building a soft sensor model.

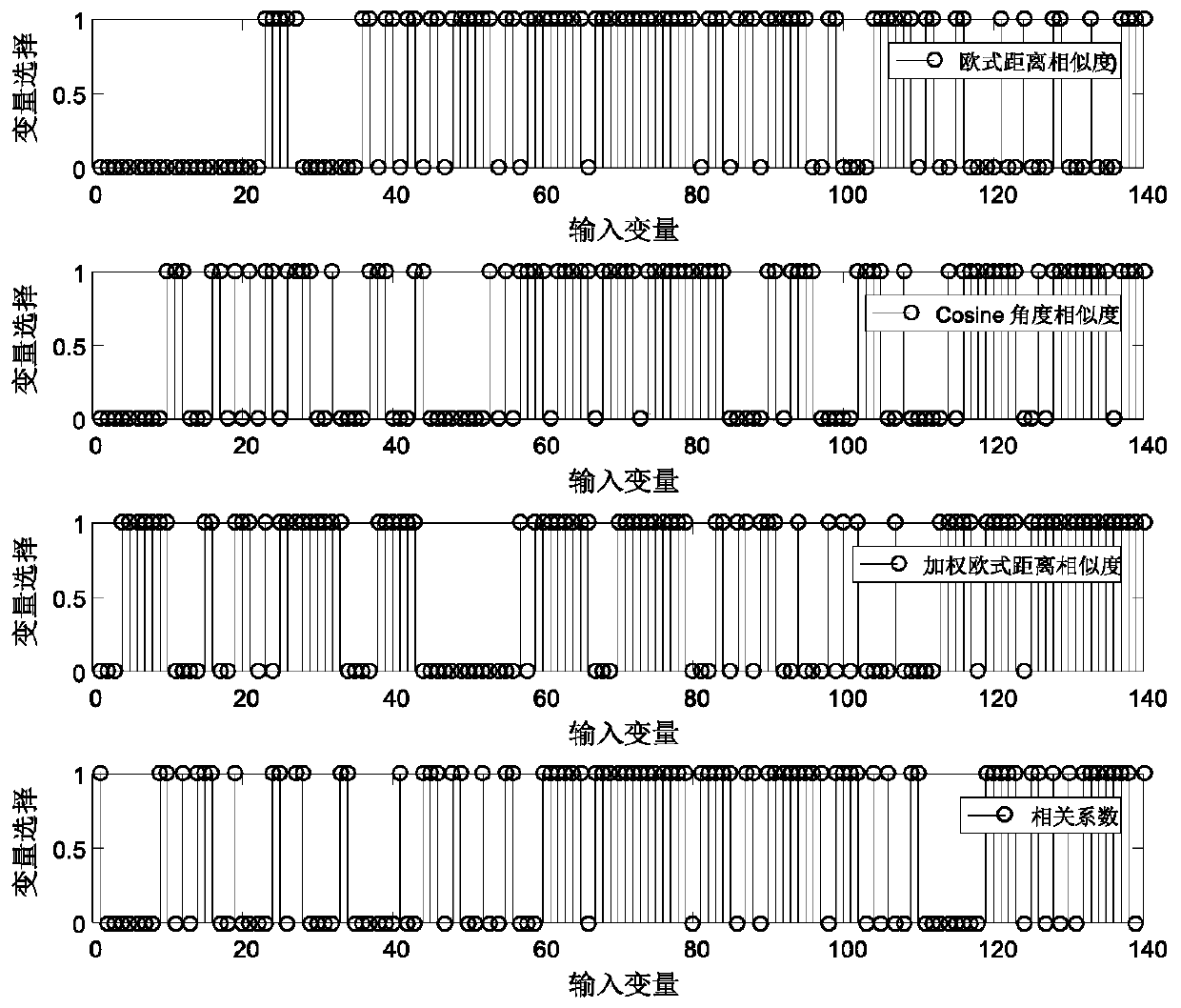

[0074] As shown in Table 1, the 5 auxiliary variables selected for the key quality variable Mooney viscosity are given, and the process variable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com