Trajectory tracking control method of agv system

A technology of trajectory tracking and control method, applied in two-dimensional position/channel control, control/adjustment system, non-electric variable control and other directions, can solve the problems of poor motion flexibility, poor motion stability, high height, and reduce construction costs. , good stability, high movement flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

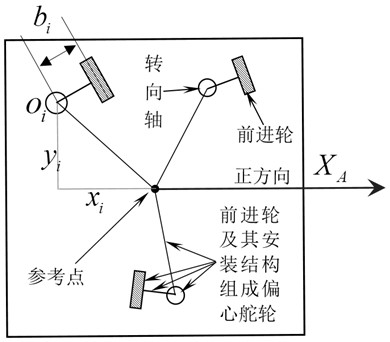

[0022] See attached figure 1 , the present invention provides an AGV system with multiple eccentric steering wheel devices, and the AGV system has at least two eccentric steering wheel devices for driving the vehicle body to move. The eccentric steering wheel device includes a driving wheel, a steering shaft for adjusting the direction of the driving wheel and necessary auxiliary installation and fixing components. The driving wheel of the eccentric steering wheel device is in contact with the ground to drive the AGV body forward; and the driving wheel is not located directly below the steering shaft but is eccentric with the steering shaft.

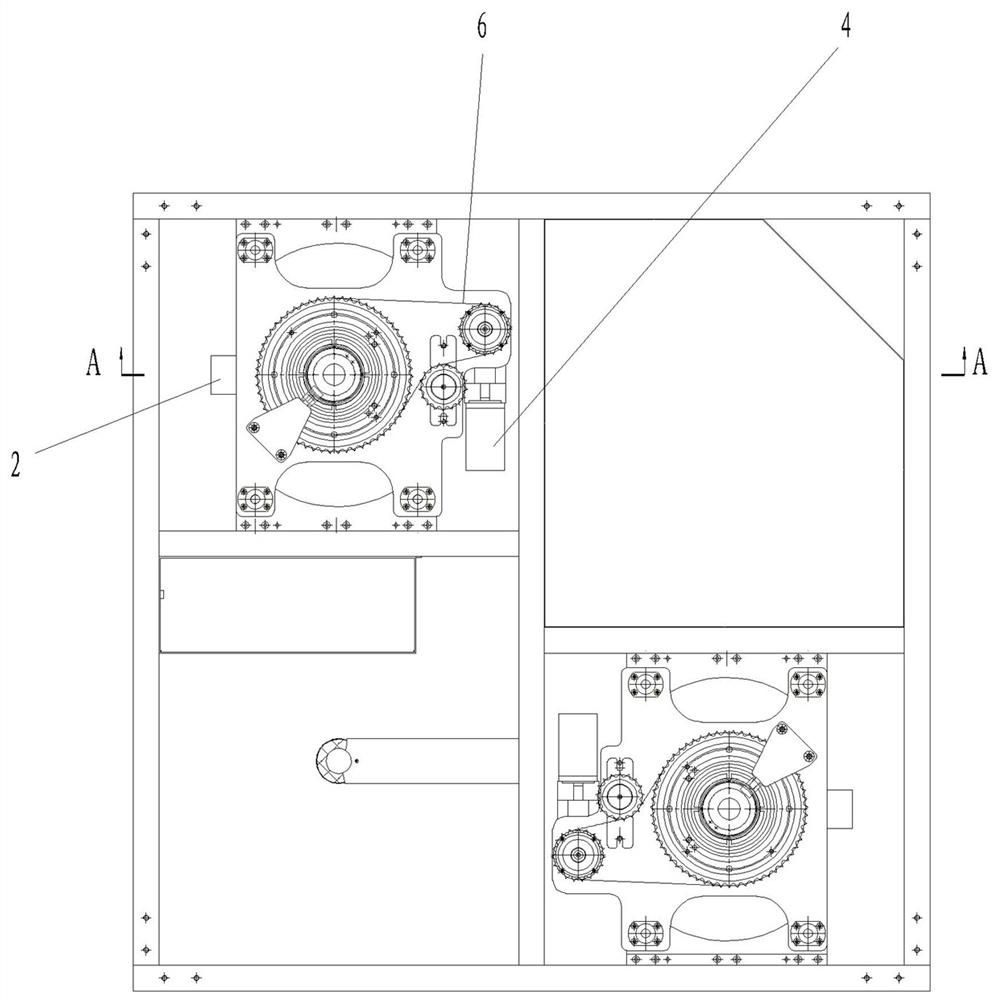

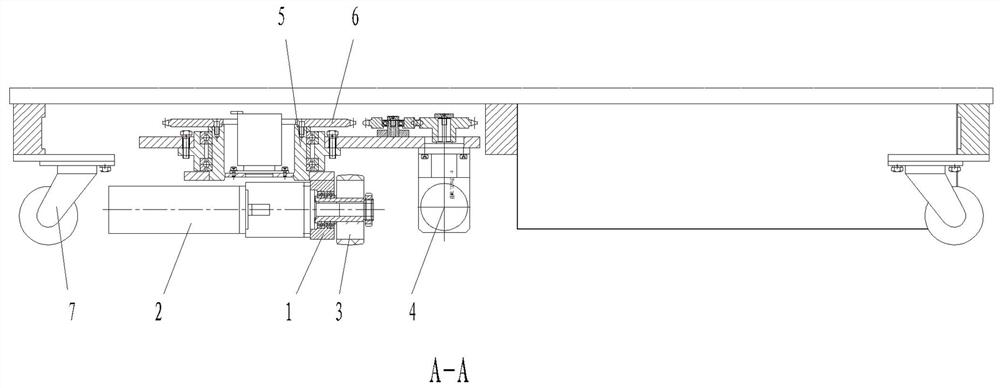

[0023] Specifically, see the attached figure 2 and 3 , The AGV system includes an AGV car body, and the AGV car body is provided with a universal wheel 7 and an eccentric steering wheel device for driving the AGV car body to move. The eccentric steering wheel device includes a steering wheel assembly and a steering drive assembly tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com