Sheet-like series shell-and-tube type heat exchanger

A shell-and-tube heat exchanger and sheet-like technology, which is applied in the field of sheet-like shell-and-tube heat exchangers connected in series, can solve the problems that it is difficult to meet the high-pressure hydrogen heat exchange and pre-cooling of hydrogen refueling stations at the same time, and achieve radial space utilization The effect of high efficiency, increased disturbance, and enhanced heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

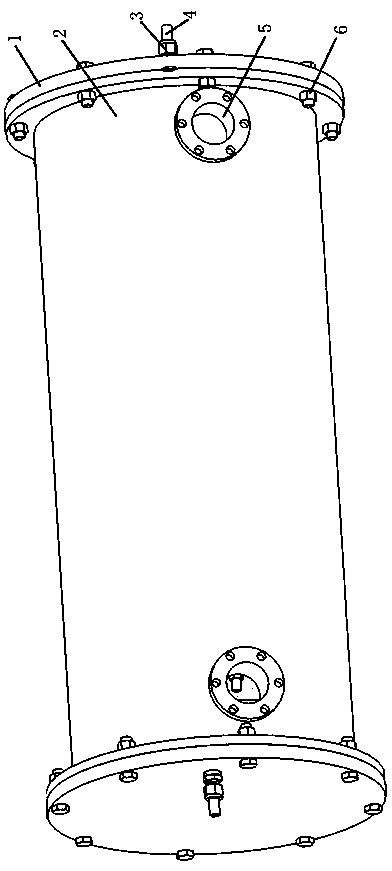

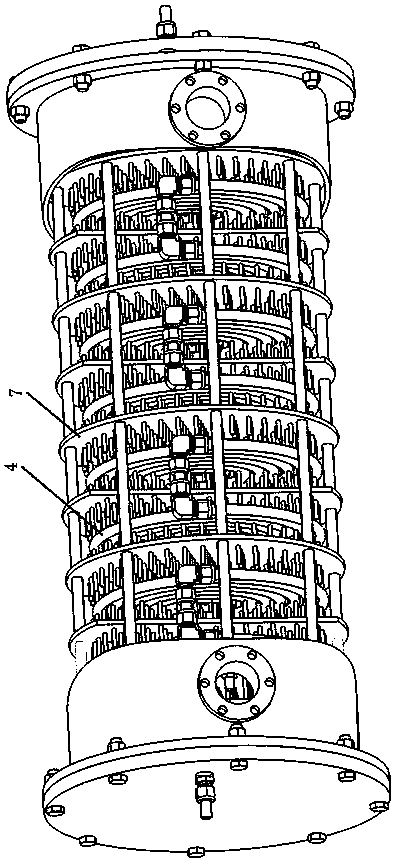

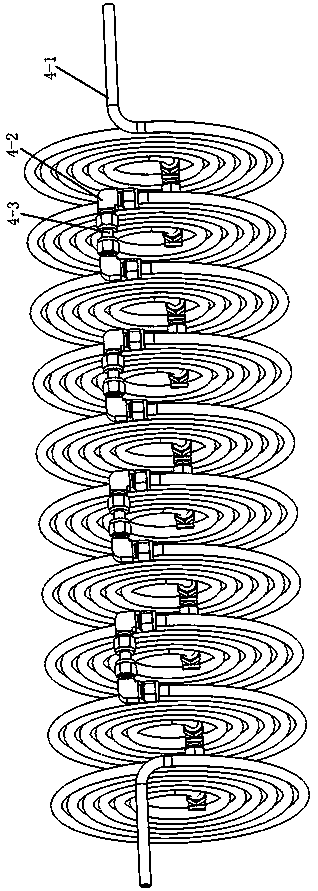

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the specific content of the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. A sheet-shaped shell-and-tube heat exchanger in series, including a shell 2 and shell end covers 1 sealed and fixed at both ends of the shell 2 by locking bolts 6, the shell 2 is provided with a shell-side liquid inlet and outlet method Lan 5, the casing end cover 1 is provided with a through-shell adapter 3, and the inside of the casing 2 is provided with a tube pass assembly 4 and a baffle assembly 7, wherein the tube pass assembly 4 consists of a plurality of sheet-like concentric circles arranged in parallel The coiled tube 4-1 is connected in series by welding or special ferrule elbow 4-2 for high pressure and the transfer pipe 4-3. The positioning rod 7-2 of a plurality of pin-fin spoilers 7-1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com