Geared hub motor of electric bicycle

A technology for electric bicycles and driving motors, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., to achieve the effects of airtight performance assurance, radial space utilization, and overall improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

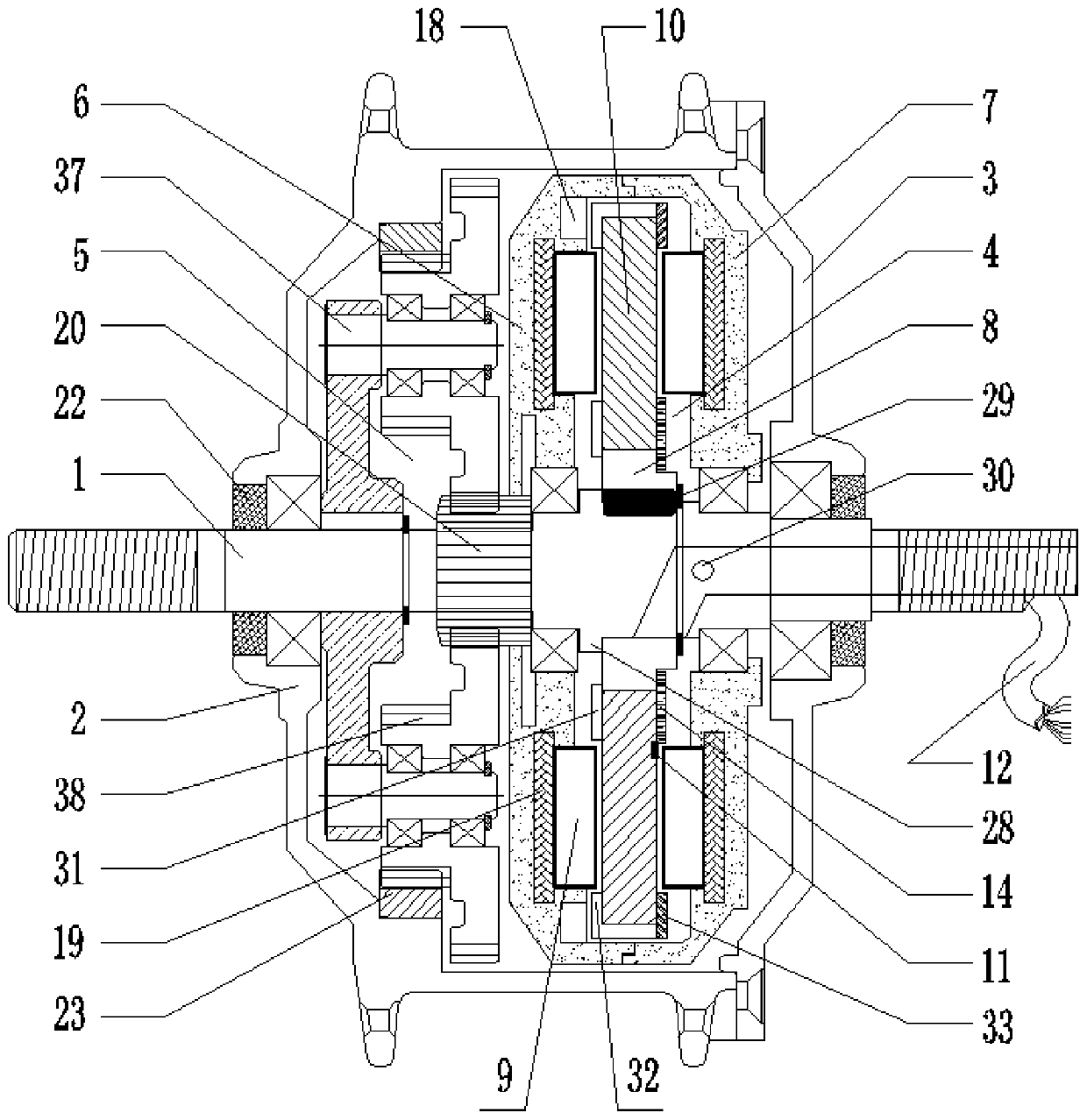

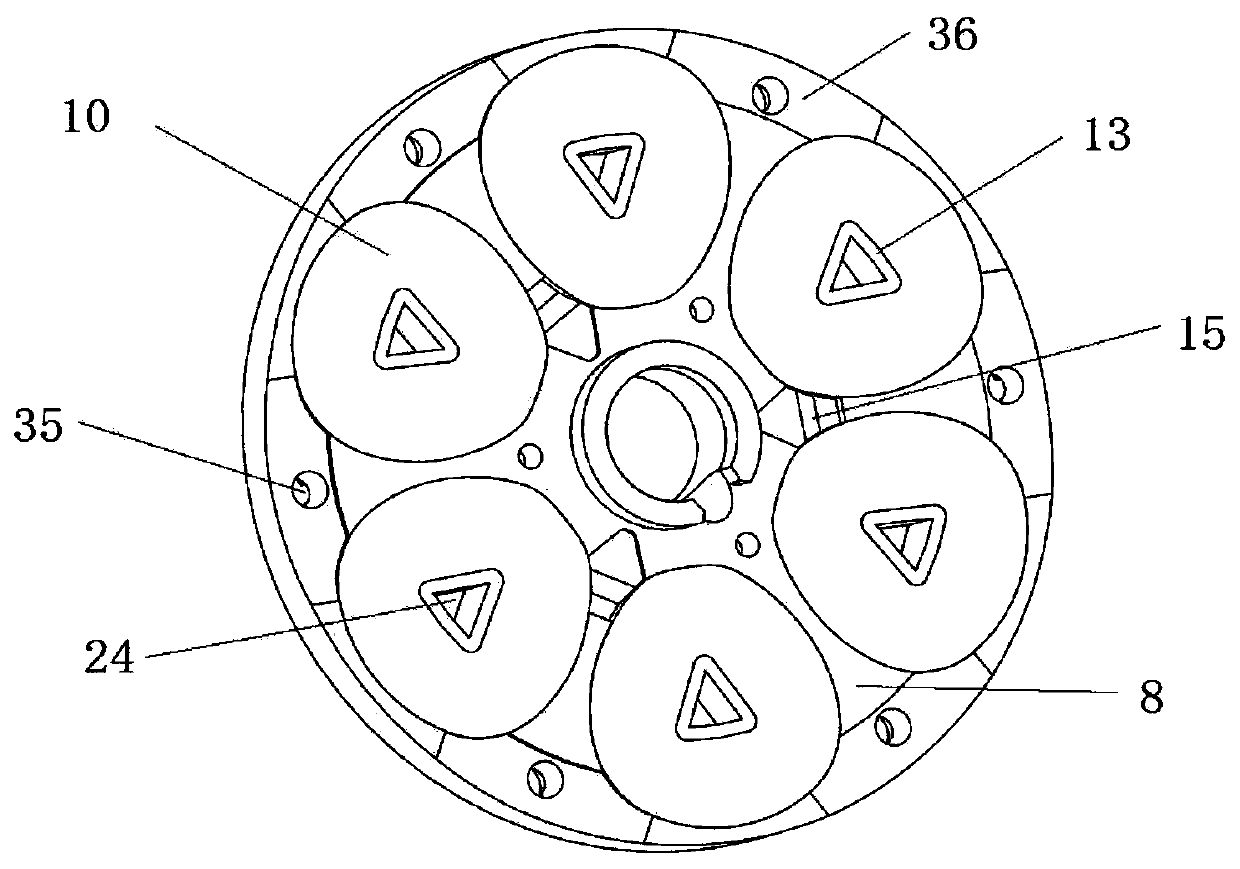

Embodiment 1

[0041] The electric bicycle has a gear hub motor with a rated voltage of 48V and a rated power of 200W. Step reduction planetary gear reduction mechanism 5 decelerates, and planetary gear reduction mechanism comprises planet carrier 37, duplex nylon planetary gear 38, central gear 23 and the sun gear ring gear 20 that is fixedly connected with motor, and the inner side of duplex planetary gear has convex block, convex gear. Bearings are installed on both sides of the gear, sleeved on the fixed shaft of the planet carrier, and locked by a circlip; the reduction ratio of the planetary gear reduction structure is set to 1:8.12; the disc-type iron-core DC motor adopts eight magnets There are 16 sector-shaped permanent magnets in total, the inner diameter of the permanent magnet is 47mm, the outer diameter is 91mm, and the axial height is 6mm. The winding of the stator disk 8 is composed of six coils 10, the diameter of the stator disk is 108mm, and the radial diameter of the coil 1...

Embodiment 2

[0043] The electric bicycle has a geared hub motor with a rated voltage of 48V, a rated power of 300W, and a 16-inch integrated hub. The driving motor is a 12-pole dual-rotor single-stator disc-type ironless DC motor with a permanent magnet inner diameter of 64mm and a radial length of 22mm. The number of winding branches is 3, the diameter of the stator disc 8 is 125mm, the radial diameter of the coil 10 is D=34mm, the height is 7.0mm, the diameter of the copper enameled wire is 0.60mm, the radial length of the ceramic triangular inner core 13 is 11.6mm, and the first-stage deceleration is adopted The planetary gear mechanism has a reduction ratio of 1:5 times. Table 1 shows the dynamometer test data of the prototype. It can be seen from the table that the highest efficiency of the prototype is 83.9%, and the input power from 58W to 542W is within the efficiency range of more than 70%. , the input power from 85W to 300W is in the high efficiency range of more than 80%, the eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Axial height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com