Brine submerging electric pump

A submersible halogen and electric pump technology, applied in the field of submerged halogen electric pumps, can solve the problems of external corrosive medium intrusion, mechanical seal damage, loss of sealing function, etc., and achieve the effects of inhibiting crystallization, reasonable structure, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

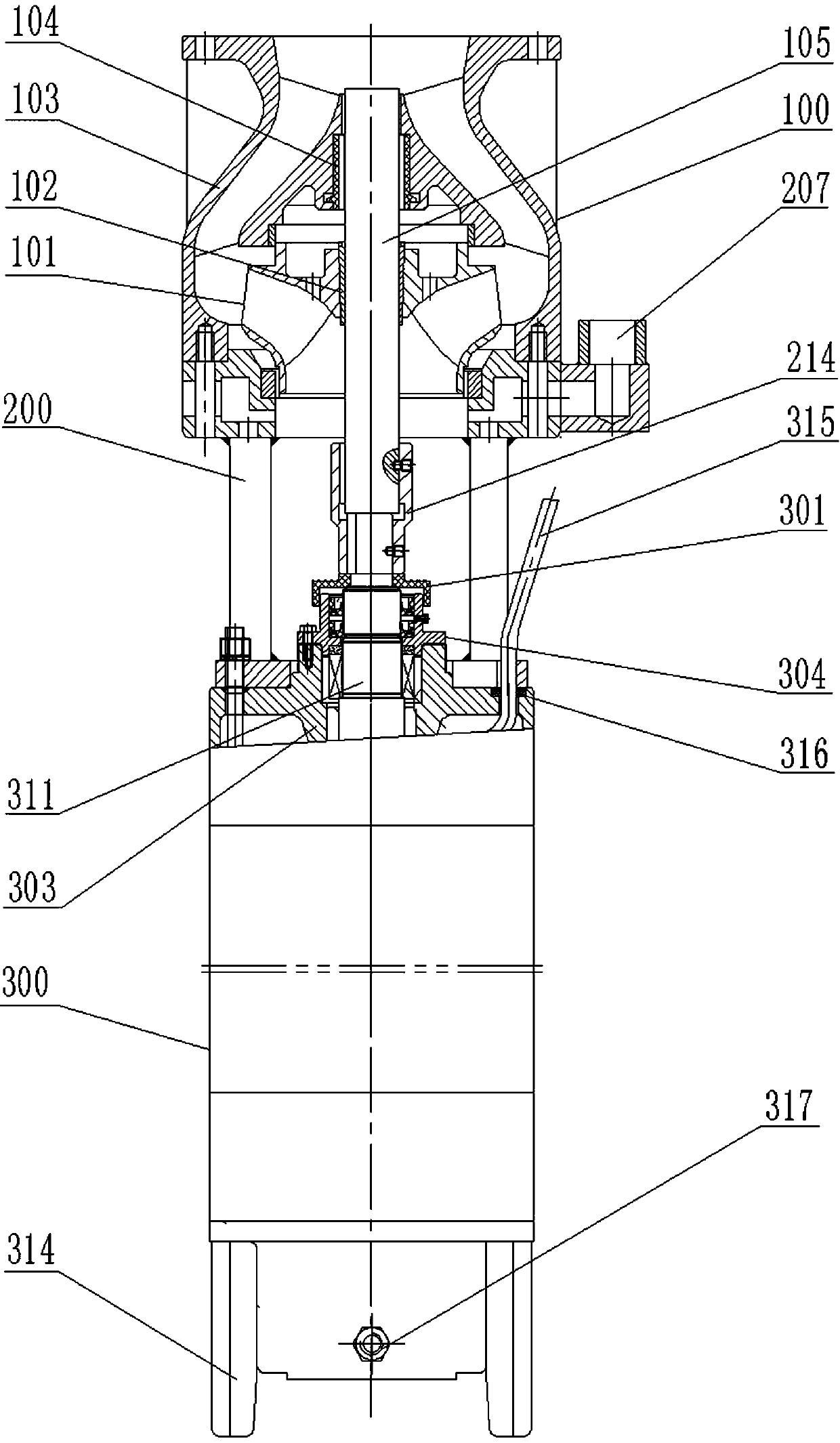

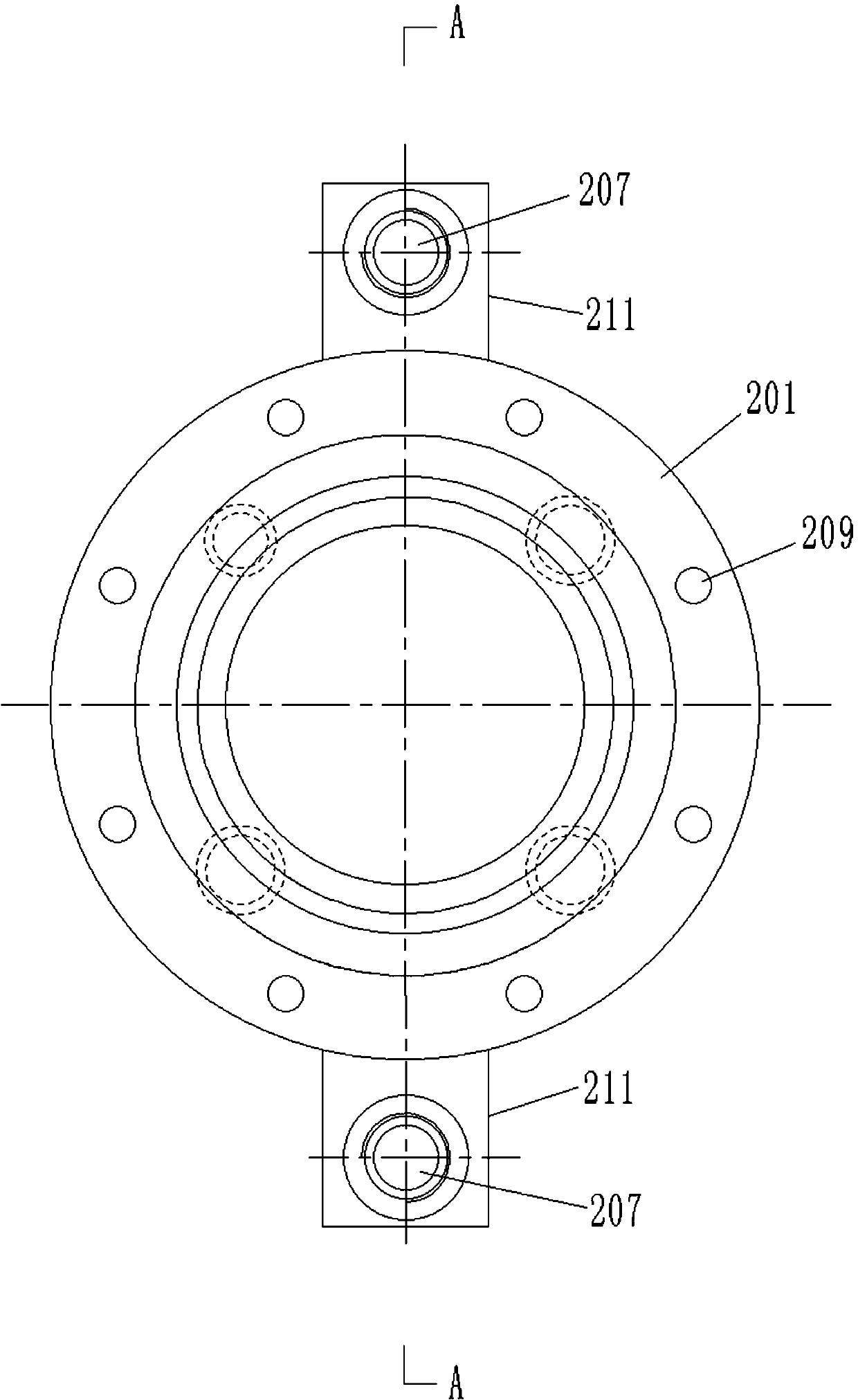

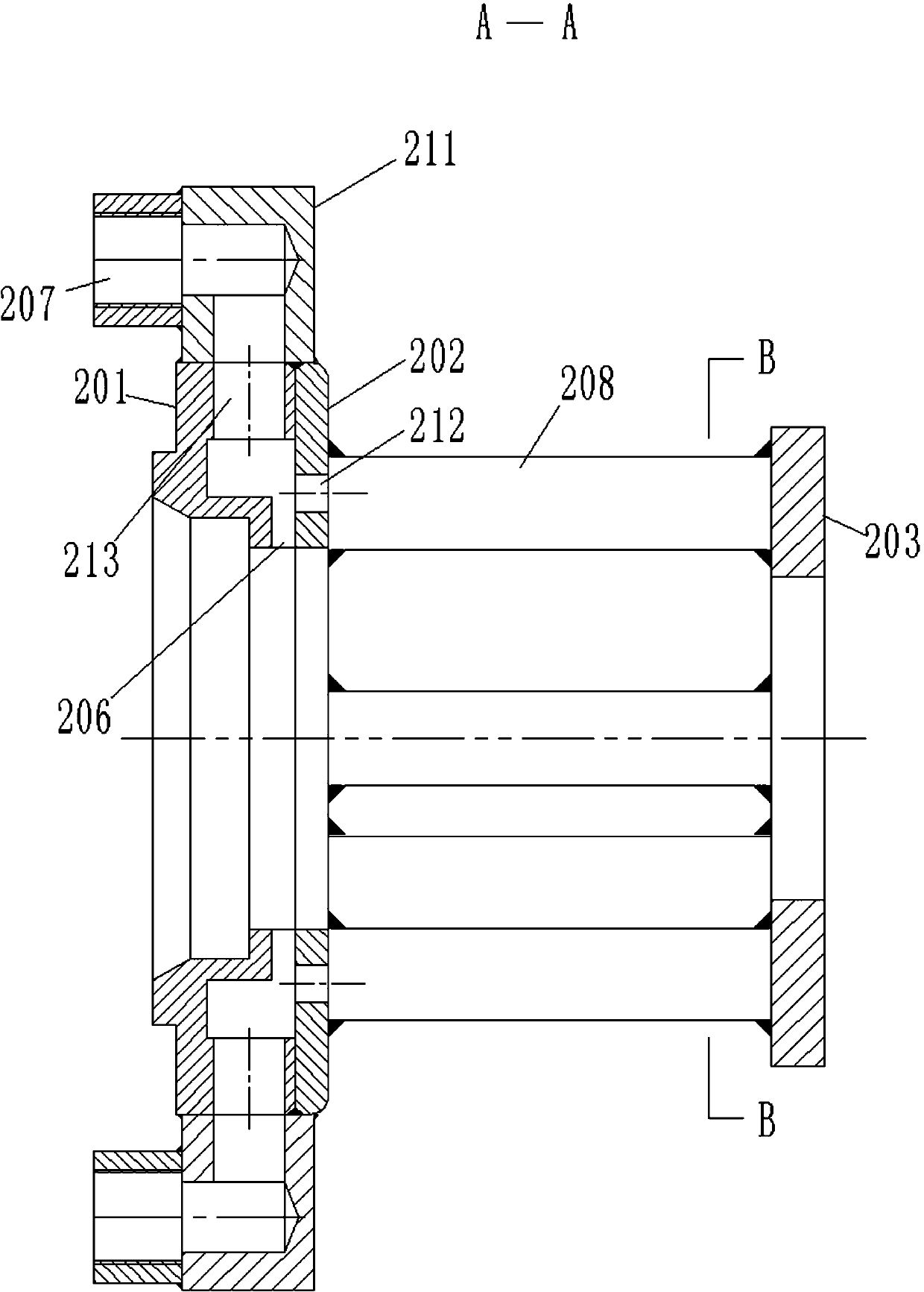

[0025] Such as Figure 1-5 As shown, a halogen submersible electric pump includes a brine submersible motor 300, a brine submersible pump 100 located above the brine submersible motor 300, and a water inlet section 200 connected between the brine submersible pump 100 and the brine submersible motor 300, and the water inlet section The outer circumference of 200 is provided with a water inlet net cover, and the water inlet section 200 includes an upper flange 201, a lower flange 203 and two or more connecting pipes 208 connected between the upper flange 201 and the lower flange 203, The outer peripheral surface of the upper flange 201 is provided with a water inlet joint 211, the water inlet joint 211 is provided with a fresh water injection port 207, the upper flange 201 is provided with a fresh water flow channel 213 communicating with the fresh water injection port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com