A detachable tooling system and building wall for laminated shear walls

A technique of superimposing shear walls and dismantling tooling, which is applied in construction, building components, building structures, etc., can solve the problems of destroying the integrity and mechanical performance of wall panels, so as to ensure accuracy, save costs, and speed up construction progress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

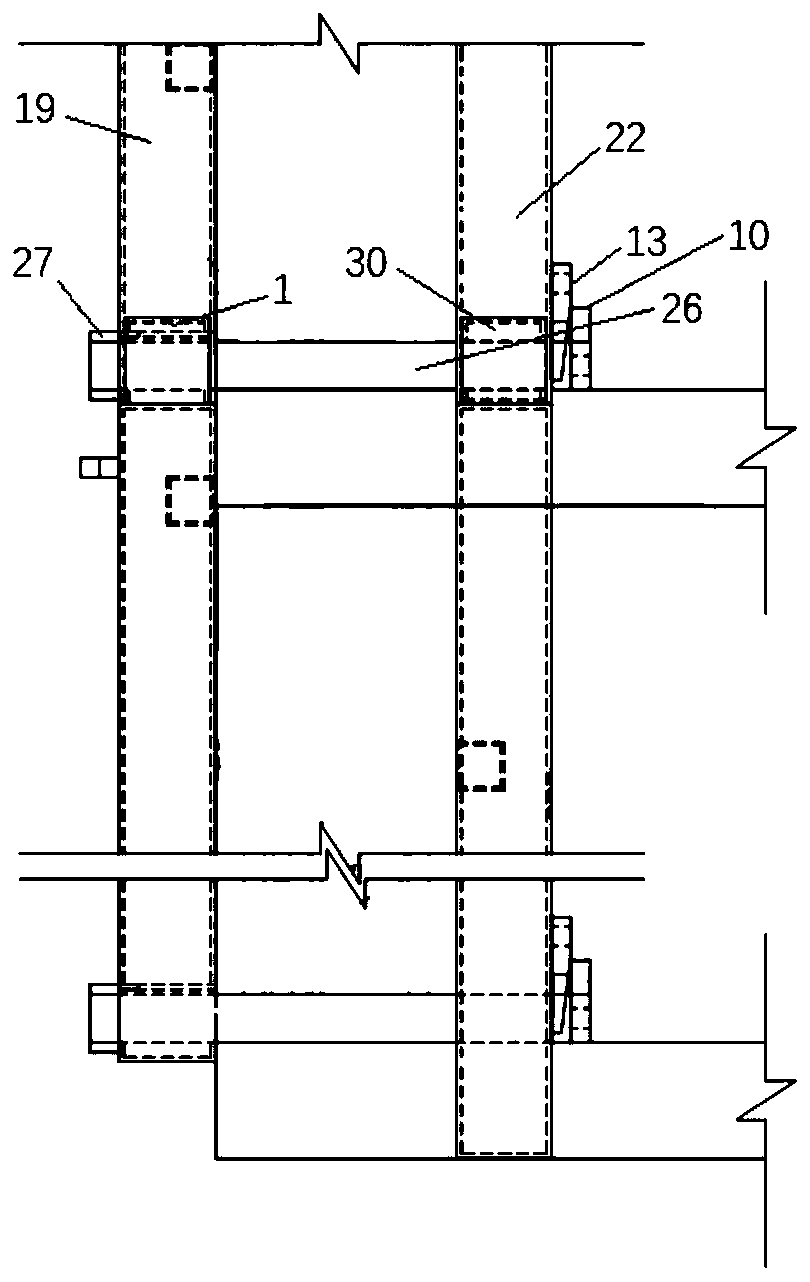

[0061] Attached below figure 1 - attached Figure 16 Further description will be made on the detachable tooling system disclosed in this embodiment;

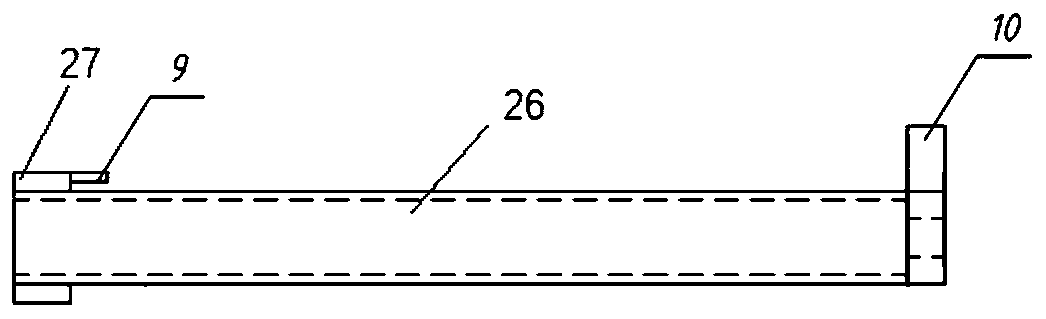

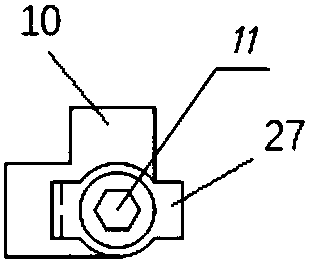

[0062] Refer to attached figure 1 As shown, the detachable tooling system for laminated shear walls includes multi-section inner steel frame units 22 connected up and down in sequence, multi-section outer steel frame units 19 connected up and down in sequence, inserts 26, and inner steel frame units 22 1. The outer steel frame units 19 are arranged side by side, and the plug-in 26 connects the steel frame units 22 in adjacent sections, the steel frame units 19 outside the adjacent sections, and connects the steel frame units 22 and 19 in the same section;

[0063] The first inter-column connecting plate 1 and the second inter-column connecting plate 30 are pierced on the plug-in 26 at intervals; The bottom is fixedly connected to the inner steel frame unit 22;

[0064] Such as figure 2 As shown, the first end of the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com