Building wall groove digging device

A technology for building walls and planing and digging, which is applied in construction, sheet pile walls, earth movers/excavators, etc., and can solve problems such as cumbersome work processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

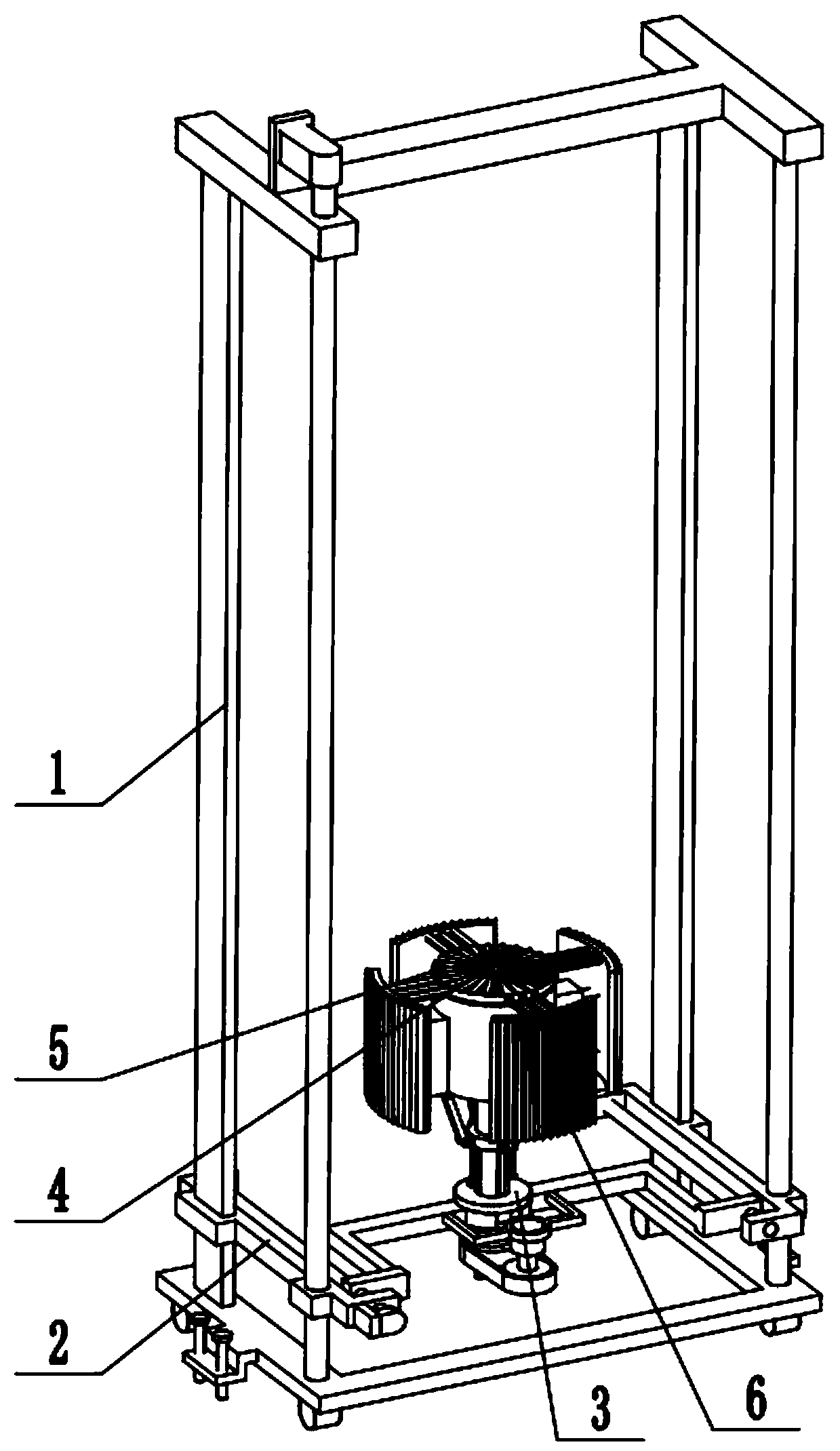

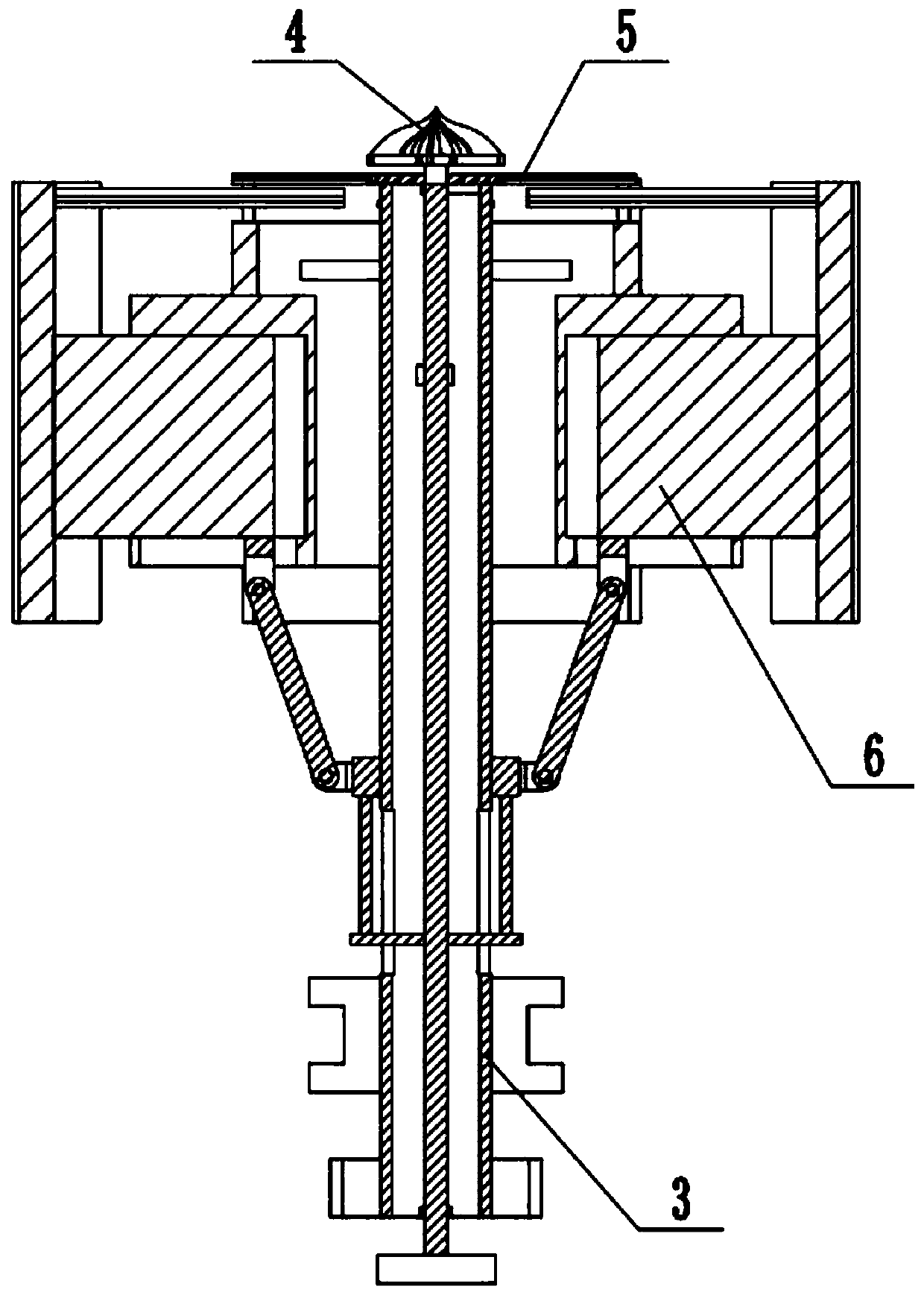

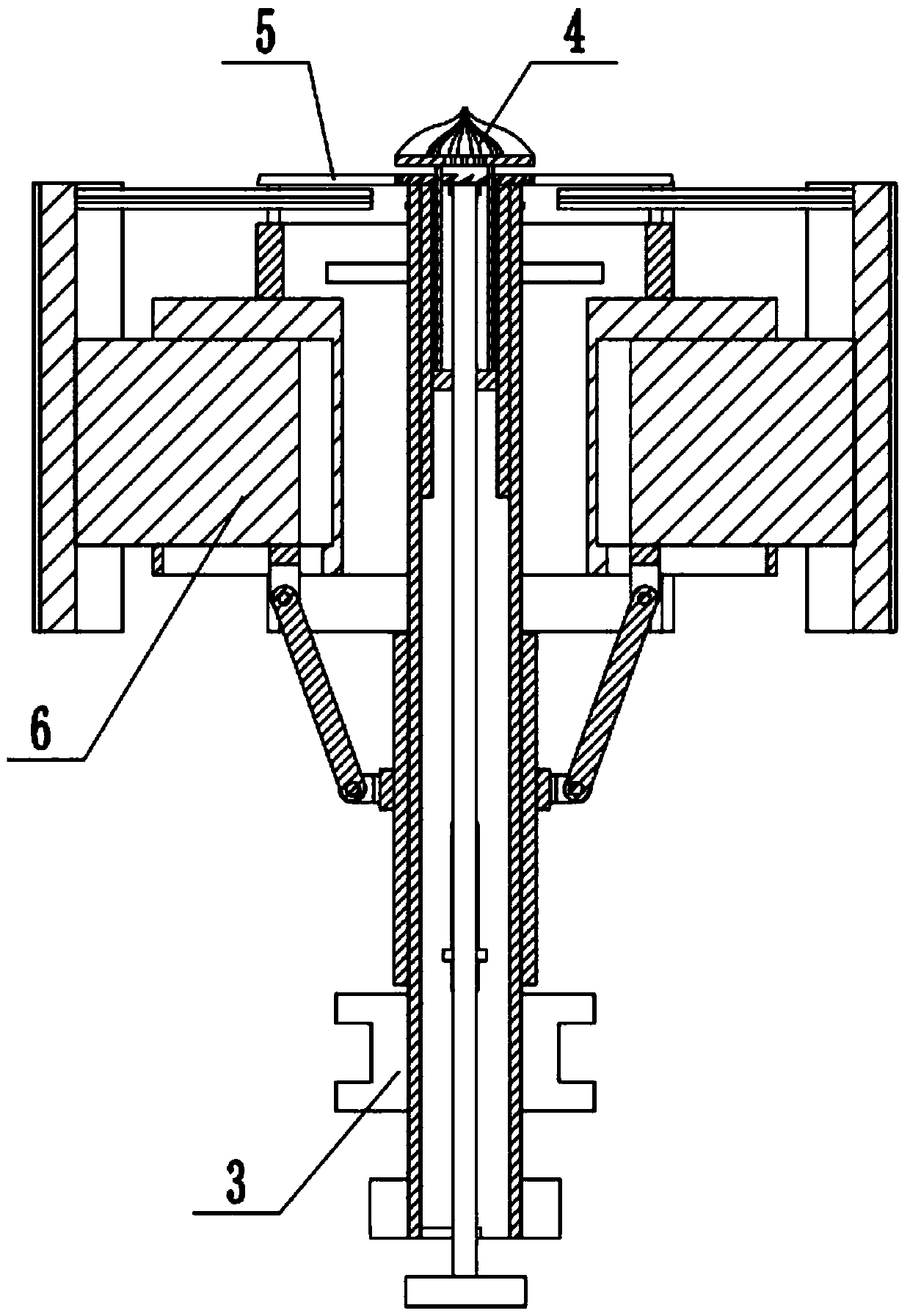

[0031] Combine below Figure 1-13 Describe this embodiment, a construction wall ditch digging device, including a support frame 1, a horizontal and vertical adjustment mechanism 2, a rotary drive member 3, a central drilling member 4, a main planing cutter head 5 and an inner wall grinding assembly 6, the The horizontal and vertical adjustment mechanism 2 is connected to the support frame 1, the rotary drive part 3 is clearance fit on the horizontal and vertical adjustment mechanism 2, the rotary drive part 3 and the horizontal and vertical adjustment mechanism 2 are connected by belt transmission, and the center drilling part 4 is connected by sliding fit. In the rotary driving part 3, the central drilling part 4 is connected with the rotary driving part 3 through thread fit, the main planing cutter head 5 is fixedly connected to the upper end of the rotary driving part 3, and the upper end of the inner wall grinding assembly 6 is fixedly connected to the rotary driving part ...

specific Embodiment approach 2

[0033] Combine below Figure 1-9 To illustrate this embodiment, the support frame 1 includes a door-shaped base 1-1, a universal wheel 1-2, a guide plate 1-3, an I-shaped plate 1-4, a longitudinal adjustment screw 1-5, and a motor Ⅰ1-6, L-shaped screw seat plate 1-7, ground screw 1-8 and guide rod 1-9; the two ends of the door-shaped base 1-1 are respectively fixedly connected with two universal wheels 1-2, two The guide plate 1-3 is symmetrically fixedly connected to the rear end of the door-shaped base 1-1, the I-shaped plate 1-4 is fixedly connected to the two guide plates 1-3, and the two ends of the longitudinal adjustment screw 1-5 are respectively Rotately connected to the door-shaped base 1-1 and the I-shaped plate 1-4 through the bearing with seat, and the two ends of the guide rod 1-9 are fixedly connected to the I-shaped plate 1-4 and the door-shaped base 1-4 respectively. 1, the longitudinal adjustment screw 1-5 and the guide rod 1-9 are located at the front end o...

specific Embodiment approach 3

[0035] Combine below Figure 1-9 To illustrate this embodiment, the horizontal and vertical adjustment mechanism 2 includes a motor II 2-1, a driving pulley 2-2, a shift fork 2-3, two left and right L-shaped linkage rods 2-4, and a horizontal adjustment screw 2-5. , left bracket 2-6, motor III 2-7, right slide bar 2-8 and right bracket 2-9; the output shaft of motor II 2-1 is fixedly connected to driving pulley 2-2, and motor II 2-1 passes through the motor frame Fixedly connected to two shift forks 2-3, the two shift forks 2-3 are arranged symmetrically, the outer ends of the two shift forks 2-3 are fixedly connected to an L-shaped linkage rod 2-4, and the left L-shaped linkage The rod 2-4 is connected to the horizontal adjustment screw 2-5 through thread fit, the horizontal adjustment screw 2-5 is rotatably connected to the left bracket 2-6 through the bearing with seat, and the motor III 2-7 is fixedly connected to the On the left bracket 2-6, the output shaft of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com