A kind of slotting equipment for sheet metal

A technology for slotting equipment and plates, which is applied in the direction of slotting machines, mortising machines, wood processing equipment, etc., which can solve the problems of low precision, inconvenient replacement of cutting wheels, and reduced processing efficiency, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

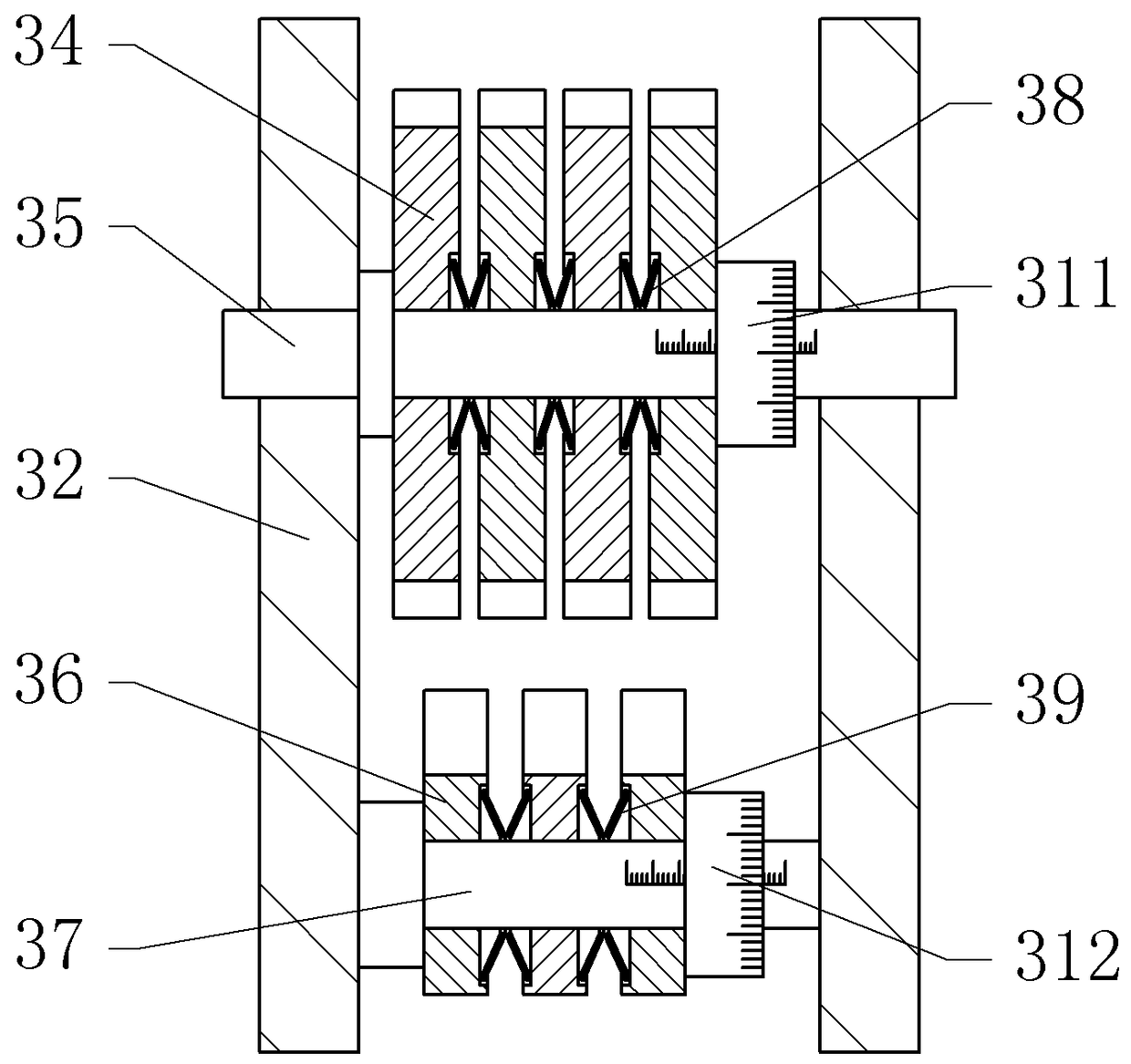

[0023] The reference signs in the accompanying drawings of the description include: workbench 10, positioning block 11, clamping block 12, clamping cylinder 13, feed rod 21, lead screw 22, seat body 31, knife rest 32, second cylinder 33, rotary Knife 34, first knife shaft 35, broach 36, second knife shaft 37, first compression spring 38, second compression spring 39, first adjustment nut 311, second adjustment nut 312.

[0024] The embodiment is basically as figure 1 , figure 2 Shown:

[0025] The slotting equipment of the sheet material of this embodiment comprises frame, workbench 10, clamping device and slotting device, and workbench 10 is fixed on the frame, and clamping device comprises positioning block 11, clamping block 12 and clamping cylinder 13. The positioning block 11 is fixed on the workbench 10 by bolts, and the position of the positioning block 11 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com