Synthesis method of 1T-phase molybdenum disulfide/carbon fiber cloth nano composite material

A technology of nanocomposite materials and carbon fiber cloth, which is applied in the direction of carbon fiber, chemical instruments and methods, fiber treatment, etc., can solve the problems of mutual agglomeration, reduction of electrocatalytic effect, reduction of effective contact area of electrolyte, etc., and achieve product stability and preparation Simple method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

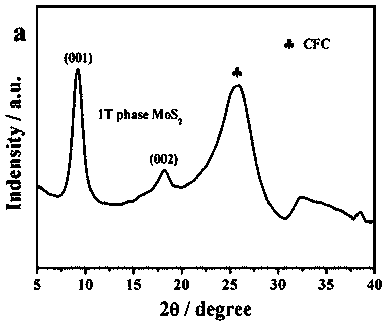

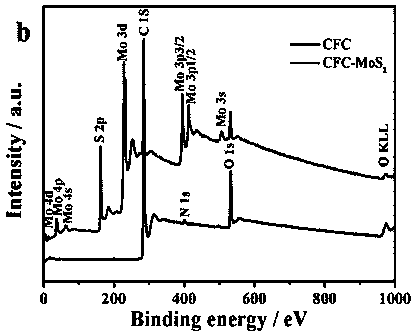

[0014] The present invention also provides a method for synthesizing 1T-phase molybdenum disulfide / carbon fiber cloth nanocomposite material, comprising the following steps: step S1: preparing solution; step S2: hydrothermal reaction; step S3: sample processing.

[0015] Preferably, the method for synthesizing 1T phase molybdenum disulfide / carbon fiber cloth nanocomposites is characterized in that: in the step S1, it is characterized in that moderate sodium molybdate and L-cysteine (concentration ratio 1:5) are dissolved In 80 mL of deionized water, stir vigorously for 30 min.

[0016] Preferably, the method for synthesizing 1T phase molybdenum disulfide / carbon fiber cloth nanocomposites is characterized in that: in the step S2, the uniform mixed solution is transferred to a 100 mL stainless steel autoclave, and a treated carbon fiber cloth (3 cm *6cm) was immersed in the mixture and heated at 200°C for 24 hours.

[0017] Preferably, the method for synthesizing 1T-phase mol...

Embodiment 2

[0019] The present invention also provides a method for synthesizing 1T-phase molybdenum disulfide / carbon fiber cloth nanocomposite material, comprising the following steps: step S1: preparing solution; step S2: hydrothermal reaction; step S3: sample processing.

[0020] Preferably, the method for synthesizing 1T phase molybdenum disulfide / carbon fiber cloth nanocomposites is characterized in that: in the step S1, it is characterized in that moderate sodium molybdate and L-cysteine (concentration ratio 1:10) dissolve In 80 mL of deionized water, stir vigorously for 30 min.

[0021] Preferably, the method for synthesizing 1T phase molybdenum disulfide / carbon fiber cloth nanocomposites is characterized in that: in the step S2, the uniform mixed solution is transferred to a 100 mL stainless steel autoclave, and a treated carbon fiber cloth ( 3cm*6cm) immersed in the mixture, heated at 200°C for 24 hours.

[0022] Preferably, the method for synthesizing 1T-phase molybdenum disu...

Embodiment 3

[0024] The present invention also provides a method for synthesizing 1T-phase molybdenum disulfide / carbon fiber cloth nanocomposite material, comprising the following steps: step S1: preparing solution; step S2: hydrothermal reaction; step S3: sample processing.

[0025] Preferably, the method for synthesizing 1T phase molybdenum disulfide / carbon fiber cloth nanocomposites is characterized in that: in the step S1, it is characterized in that moderate sodium molybdate and L-cysteine (concentration ratio 1:15) dissolve In 80 mL of deionized water, stir vigorously for 30 min.

[0026] Preferably, the method for synthesizing 1T phase molybdenum disulfide / carbon fiber cloth nanocomposites is characterized in that: in the step S2, the uniform mixed solution is transferred to a 100 mL stainless steel autoclave, and a treated carbon fiber cloth ( 3cm*6cm) immersed in the mixture, heated at 200°C for 24 hours.

[0027] Preferably, the method for synthesizing 1T-phase molybdenum disu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com