Special cerate for redwood furniture

A technology of mahogany furniture and wax paste, applied in the direction of polishing composition, chemical instruments and methods, etc., can solve the problems of wax paste cannot nourish, poor stability, etc., achieve the effect of enhancing aesthetics, enhancing stability, and reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

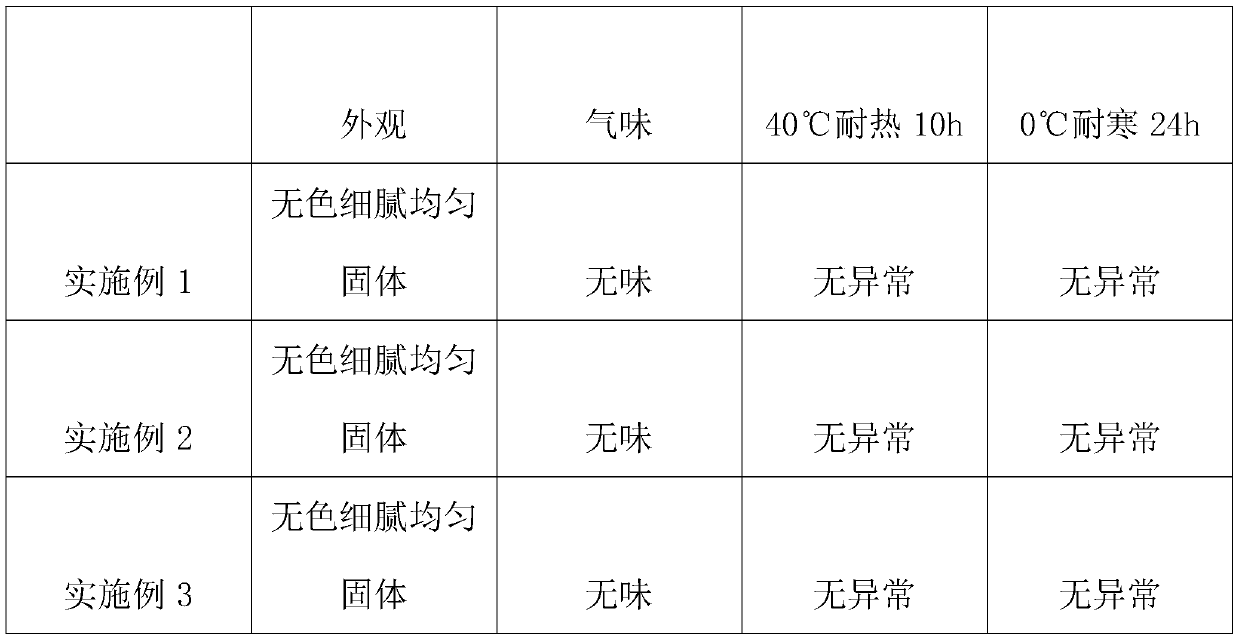

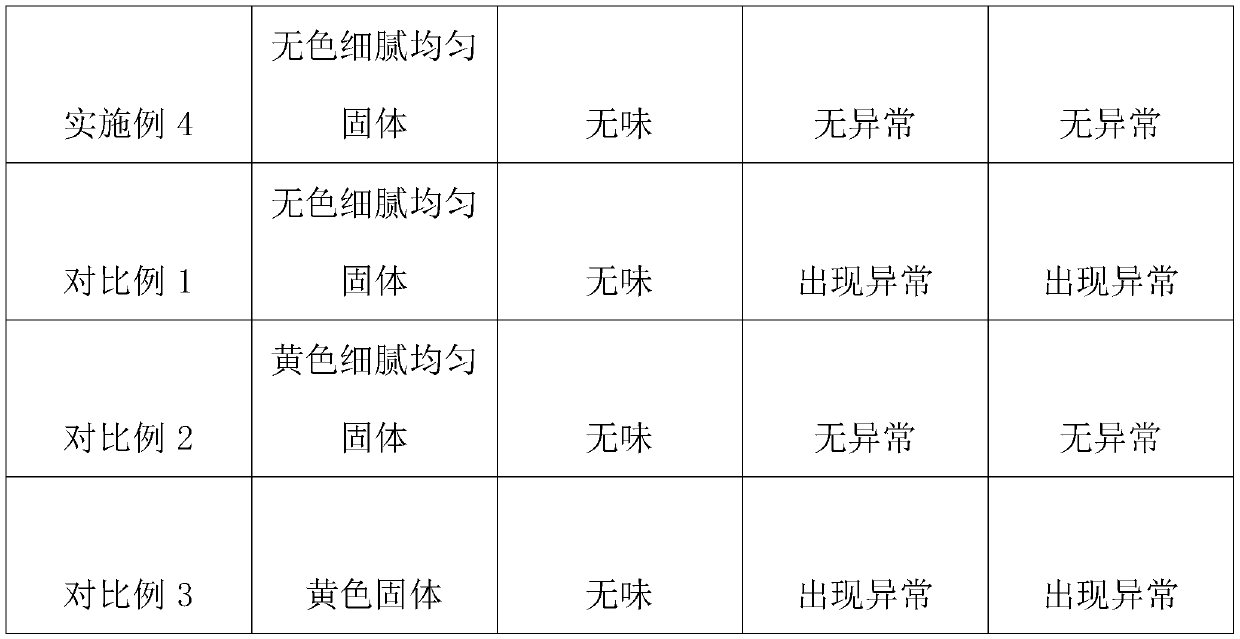

Examples

Embodiment 1

[0036] A special wax paste for mahogany furniture, made of the following raw materials in parts by weight: 10 parts of expansive clay, 20 parts of modified silicone oil emulsion, 15 parts of beeswax, 10 parts of tung oil, 15 parts of microcrystalline wax, 10 parts of rice bran wax, and 3 parts of laurel Sodium alcohol sulfate, 50 parts of absolute ethanol, 3 parts of sodium tripolyphosphate, 5 parts of ethoxylated lauramide, 25 parts of deionized water;

[0037] The special wax paste for mahogany furniture is made by the following method:

[0038] Step S1, pretreatment: Put expansive soil in a muffle furnace for calcination at 350°C for 1 hour, then add 100mL of 10% sodium chloride solution, heat in a water bath at 70°C for 2 hours, add 50mL of 10% dilute hydrochloric acid solution, heat up to 70°C, ultrasonicate, stir 20min, filter, put the filter residue in a beaker, rinse with deionized water until the solution is neutral, filter again, put the filter residue in a drying ov...

Embodiment 2

[0048] A special wax paste for mahogany furniture, made of the following raw materials in parts by weight: 12 parts of expansive soil, 22 parts of modified silicone oil emulsion, 18 parts of beeswax, 12 parts of tung oil, 16 parts of microcrystalline wax, 12 parts of rice bran wax, and 5 parts of laurel Sodium alcohol sulfate, 55 parts of absolute ethanol, 4 parts of sodium tripolyphosphate, 6 parts of ethoxylated lauramide, 28 parts of deionized water;

[0049] The special wax paste for mahogany furniture is made by the following method:

[0050] Step S1, pretreatment: Put expansive soil in a muffle furnace for calcination at 350°C for 1 hour, then add 100mL of 10% sodium chloride solution, heat in a water bath at 70°C for 2 hours, add 50mL of 10% dilute hydrochloric acid solution, heat up to 70°C, ultrasonicate, stir 20min, filter, put the filter residue in a beaker, rinse with deionized water until the solution is neutral, filter again, put the filter residue in a drying ov...

Embodiment 3

[0056] A special wax paste for mahogany furniture, made of the following raw materials in parts by weight: 15 parts of expansive soil, 24 parts of modified silicone oil emulsion, 23 parts of beeswax, 18 parts of tung oil, 18 parts of microcrystalline wax, 14 parts of rice bran wax, and 6 parts of laurel Sodium alcohol sulfate, 65 parts of absolute ethanol, 6 parts of sodium tripolyphosphate, 8 parts of ethoxylauramide, 35 parts of deionized water;

[0057] The special wax paste for mahogany furniture is made by the following method:

[0058] Step S1, pretreatment: Put expansive soil in a muffle furnace for calcination at 350°C for 1 hour, then add 100mL of 10% sodium chloride solution, heat in a water bath at 70°C for 2 hours, add 50mL of 10% dilute hydrochloric acid solution, heat up to 70°C, ultrasonicate, stir 20min, filter, put the filter residue in a beaker, rinse with deionized water until the solution is neutral, filter again, put the filter residue in a drying oven at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com