Method for depolymerizing and purifying TPA by using waste polyester textiles and adding film-blowing LDPE for modification

A polyester and modified technology, which is used in the field of extrusion special alloy new materials, can solve the problems that cannot be directly reprocessed, cannot be reused, landfill or incinerate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] A method of chemically depolymerizing and purifying TPA with polyester waste textiles according to the present invention, adding extrusion grade LDPE material, and modifying it into a special alloy material for extrusion is carried out according to the following process procedures:

[0010] Depolymerize polyester waste textiles with glycerin residue heated to 260-280 degrees, filter the dregs in the solution, decolorize and purify to obtain liquid TPA. Prepare TPA plus LDPE extrusion grade raw materials in the following parts by weight.

[0011] TPA 10 parts

[0012] Extrusion grade LDPE 85 parts

[0013] Compatibility modifier 5 parts

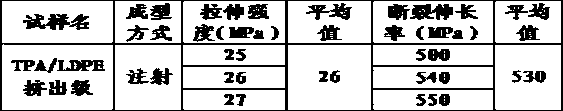

[0014] Test results

[0015]

[0016] The above-mentioned prepared components and parts by weight are mixed, extruded and granulated, and a new TPA / LDPE extrusion-grade alloy material is obtained.

Embodiment 2

[0018] Referring to the method of Example 1, each component and parts by weight were prepared in the following proportions to prepare TPA plus LDPE extrusion grade raw materials.

[0019] TPA 20 parts

[0020] Extrusion grade LDPE 75 parts

[0021] Compatibility modifier 5 parts

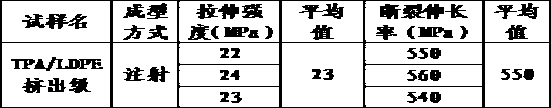

[0022] Test results

[0023]

[0024] The above-mentioned prepared components and parts by weight are mixed, extruded and granulated, and a new TPA / LDPE extrusion-grade alloy material is obtained.

Embodiment 3

[0026] Referring to Examples 1 and 2, prepare TPA plus LDPE extrusion grade raw materials with each component and parts by weight in the following proportions.

[0027] 30 parts of TPA

[0028] Extrusion grade LDPE 65 parts

[0029] Compatibility modifier 5 parts

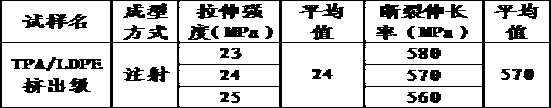

[0030] Test results

[0031]

[0032] The above-mentioned prepared components and parts by weight are mixed, extruded and granulated, and a new TPA / LDPE extrusion-grade alloy material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com