Preparation method of benzotriazole derivatives

A technology of benzotriazole derivatives and benzotriazole, which is applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of environmental protection and economy, difficult removal, complicated preparation, etc., and achieve simple post-treatment, less side reactions, The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

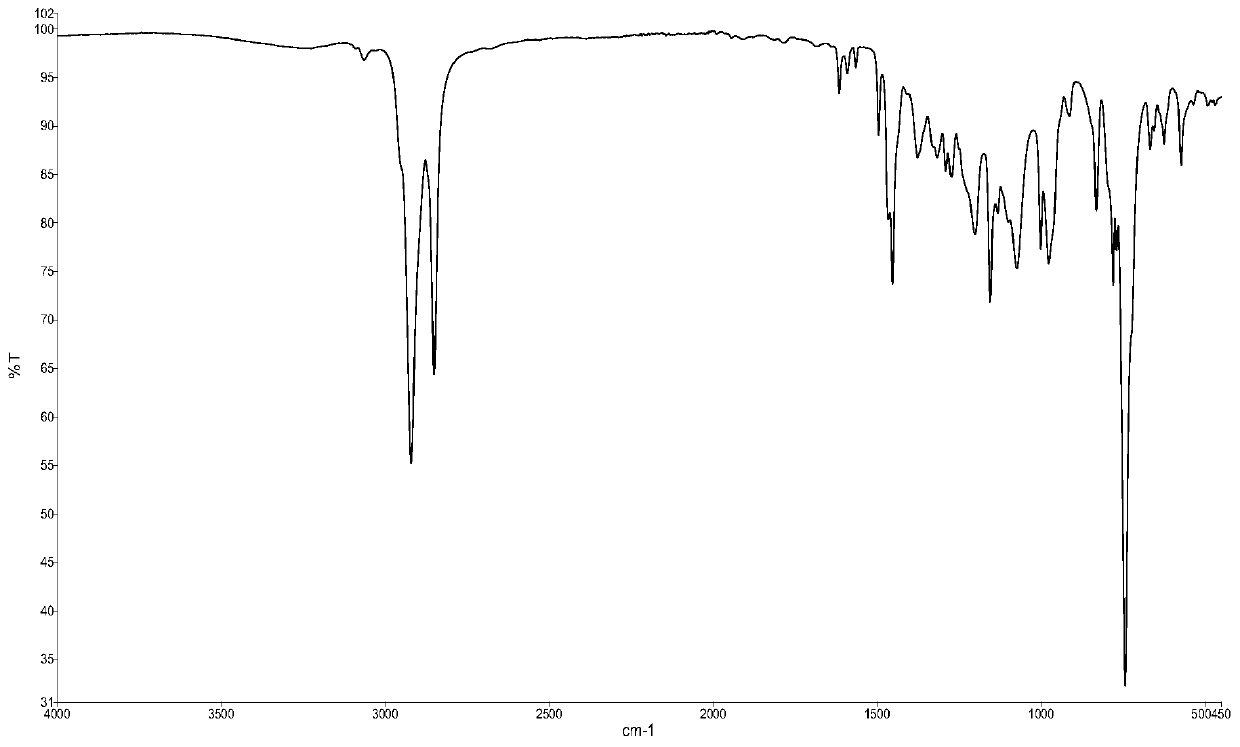

Image

Examples

preparation example Construction

[0028] The invention provides a preparation method of benzotriazole derivatives, comprising: under certain conditions, performing Mannich and electrophilic addition of benzotriazole (benzotriazole), formaldehyde and octadecylamine in an organic solvent reaction to generate benzotriazole derivatives.

[0029] Specifically:

[0030] Mix benzotriazole and octadecylamine with a certain amount of organic solvent, heat, dissolve, and keep warm; then slowly add formaldehyde at a certain temperature to carry out aminomethylation reaction; finally carry out Mannich reaction under reflux conditions. And electrophilic addition reaction, generate benzotriazole derivatives.

[0031] Wherein, the reaction process of benzotriazole, formaldehyde and octadecylamine according to a certain feed ratio under reflux conditions according to the present invention is:

[0032] S1,

[0033] S2,

[0034] S3,

[0035] S4,

[0036] Further, no catalyst is used in the preparation method of th...

Embodiment 1

[0050]Add 119g of benzotriazole, 134.5g of octadecylamine, 120g of ethanol and 125g of 120# gasoline in a 1000ml four-necked flask equipped with a thermometer and a condenser. Nitrogen gas was passed into the reaction bottle, and after the air in the bottle was fully replaced, heating was started. Start stirring when the temperature reaches about 30°C, and the stirring rate is 350 rpm. Gradually raise the temperature to 45°C, keep it warm for half an hour, add 98.5g of formaldehyde solution to the dropping device, slowly drop the formaldehyde solution at 45°C to start the reaction, after the dropwise addition, react at this temperature for 1.5h, and then continue to heat up React at 70-72°C for 4 hours under reflux, stop the reaction; cool the reaction to room temperature, add 125 grams of 120# gasoline for extraction, and then perform layered filtration to obtain an organic phase and an aqueous phase. Pour the organic phase into another three-necked flask, reduce and evapora...

Embodiment 2

[0053] Add 121.8g of benzotriazole, 121.1g of octadecylamine and 240g of ethanol in a 1000ml four-necked flask equipped with a thermometer and a condenser. Nitrogen gas was passed into the reaction bottle, and after the air in the bottle was fully replaced, heating was started. Start stirring when the temperature reaches about 30°C, and the stirring rate is 350 rpm. Gradually raise the temperature to 45°C, keep it warm for half an hour, add 101.3g of formaldehyde solution to the dropping device, slowly add formaldehyde solution dropwise at 45°C to start the reaction, after the addition is complete, continue to heat up at 82-84°C, Under the state of reaction for 4 hours, the reaction was stopped; the reaction was cooled to normal temperature, and 350 grams of 120# gasoline was added for extraction, followed by layered filtration to obtain an organic phase and an aqueous phase. Pour the organic phase into another three-necked flask, reduce and evaporate to 150°C under the condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com