Method for improving water stability of porous polyurethane mixture

A water stability, polyurethane technology, applied in the field of road building materials preparation, can solve the problems of poor water stability, insufficient stability, poor water stability, etc., to fill the gap in the industry and solve the effect of poor water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

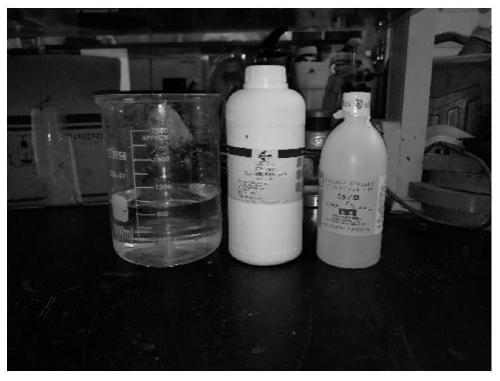

Image

Examples

Embodiment 1

[0056] 1. According to the corresponding national standards, test the performance parameters of the one-component polyurethane adhesive, the specific parameters are shown in Table 1

[0057] Table 1 Performance parameters of one-component polyurethane adhesive

[0058]

[0059]

[0060] 2. Determine the type and gradation of the aggregate and design the mix ratio

[0061] The gradation design of the porous polyurethane mixture refers to the OGFC-13 asphalt mixture, and is carried out within the mineral material gradation range specified in the "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004). The gradation composition is shown in Table 2.

[0062] Table 2 Gradation Composition

[0063]

[0064] 3. Polyurethane adhesive mixed with aggregate

[0065] Adhesive dosage is 5.9% of aggregate mass.

[0066] 4. Use of silane coupling agent

[0067] (1) Parameters of three silane coupling agents

[0068] KH550, the chemical name is γ-aminopr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com