Scraper device, solder paste printing machine and manufacturing method of circuit board

A solder paste printing machine and printed circuit board technology, which is applied in the direction of assembling printed circuits with electrical components, printing machines, rotary printing machines, etc., can solve problems such as the decline in chip production efficiency, fast chip placement, and affecting chip placement efficiency , to achieve the effect of improving efficiency, avoiding patch operation, and speeding up the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] SMT (Surface Mounting Technology, surface mount technology), also known as surface mount or surface mount technology, is currently the most popular technology and process in the electronics assembly industry. It is a surface mount component (referred to as SMC / SMD, Chinese called chip component) packaged in a matrix arrangement without leads or short leads or balls, mounted on the surface of a printed circuit board (PCB) or On the surface of other substrates, the circuit assembly technology is soldered and assembled by methods such as reflow soldering or dip soldering.

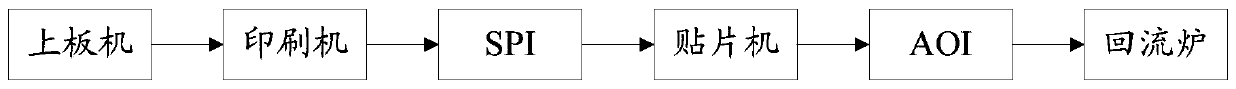

[0020] refer to figure 1 , figure 1 It is the first flow diagram of the SMT process provided by the embodiment of the present application. The SMT process mainly includes a board loading machine, a printing machine, SPI (solder paste inspection, solder paste inspection), a placement machine, and AOI (Automated Optical Inspection, automatic optical inspection) , Six processes of reflow furnace.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com