Electric screwdriver with adjustable torsion

An electric screwdriver and torque adjustment technology, applied in screwdrivers, power tools, wrenches, etc., can solve the problems affecting the practicability of electric screwdrivers and the prompt of inability to torque gears, so as to increase practicability, reduce operation difficulty, and improve The effect of using the experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

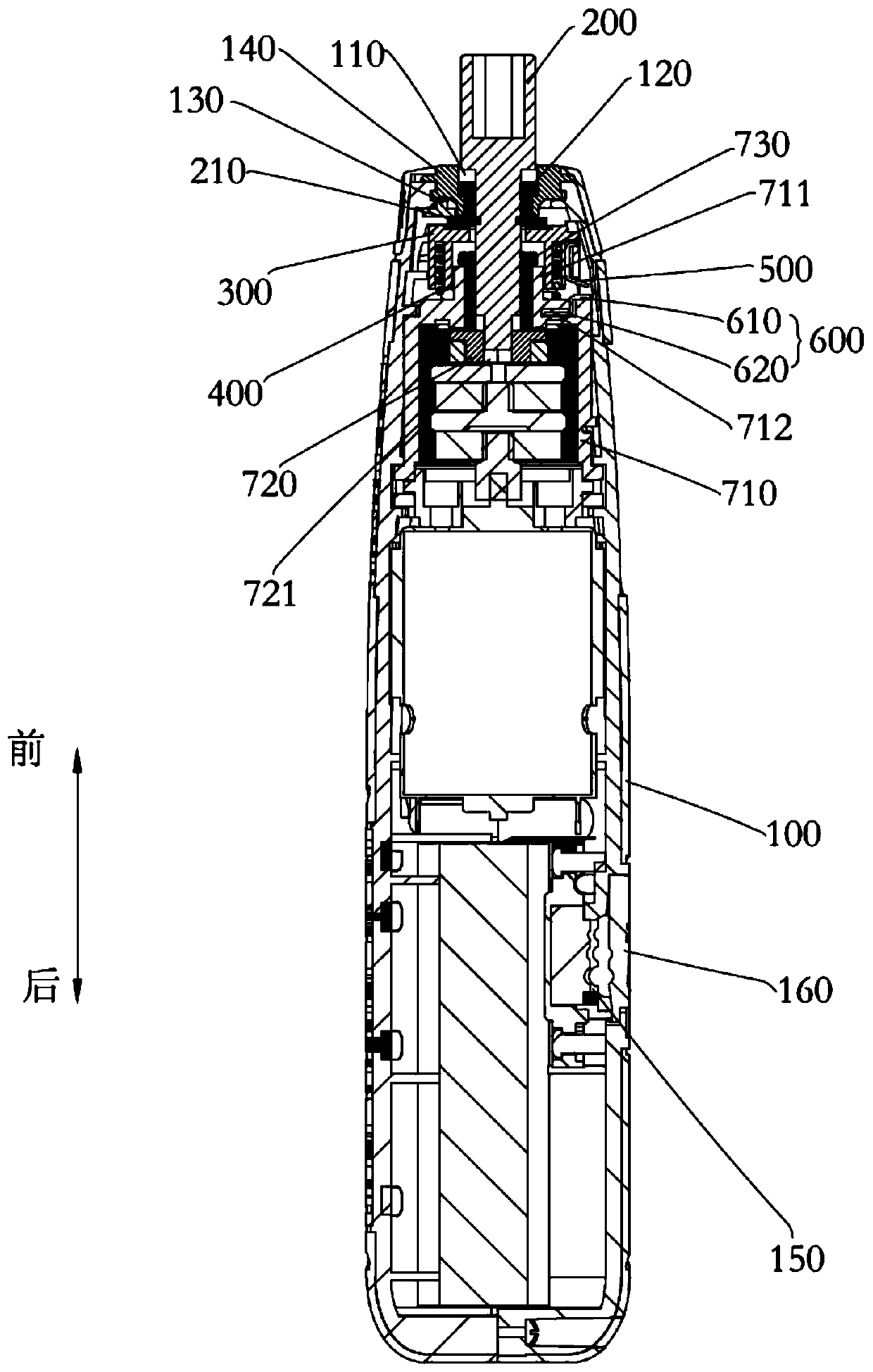

[0039]The invention discloses an electric screwdriver with adjustable torque. A torque adjustment circuit is arranged in the electric screwdriver. The torque adjustment circuit includes a torque adjustment button and a micro control unit electrically connected with the torque adjustment button. The peripheral of the micro control unit is also electrically connected to the memory chip that stores the current torque gear value and the protection current corresponding to each torque gear value, as well as the LED array; when the torque adjustment button is pressed, the trigger torque adjustment signal is transmitted to the micro control unit, and the micro The control unit obtains the current torque gear value from the memory chip, adds one to the current torque gear value, and transmits the torque gear value after the one-plus operation to the memory chip to replace the stored current torque gear value , and at the same time adjust the lighting quantity of the LEDs in the LED arr...

Embodiment 2

[0052] The invention discloses an electric screwdriver, which comprises a handle housing, a driving mechanism, an output shaft and a working circuit connected with the driving mechanism. The driving mechanism is installed in the handle housing and drives the output shaft to rotate. The output shaft can slide relative to the drive mechanism and the handle housing along its axial direction, and a pressure block and an elastic member located in front of the drive mechanism are also installed in the handle housing, and the working circuit includes a pressure block mounted on the pressure block The upper contact piece and the lower contact piece installed at the front end of the driving mechanism, the elastic member is sandwiched between the pressure block and the driving mechanism to keep the upper contact piece away from the lower contact piece, the output shaft After being pressed, the pressure block is driven to drive the upper contact piece to move, so that the upper contact pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com