Energy-saving and environmentally friendly industrial waste gas treatment device

A technology of industrial waste gas and treatment equipment, which is applied in the direction of gas treatment, combustion type, transportation and packaging, etc., and can solve the problems of incomplete reaction of substances in waste gas, cumbersome engineering, accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

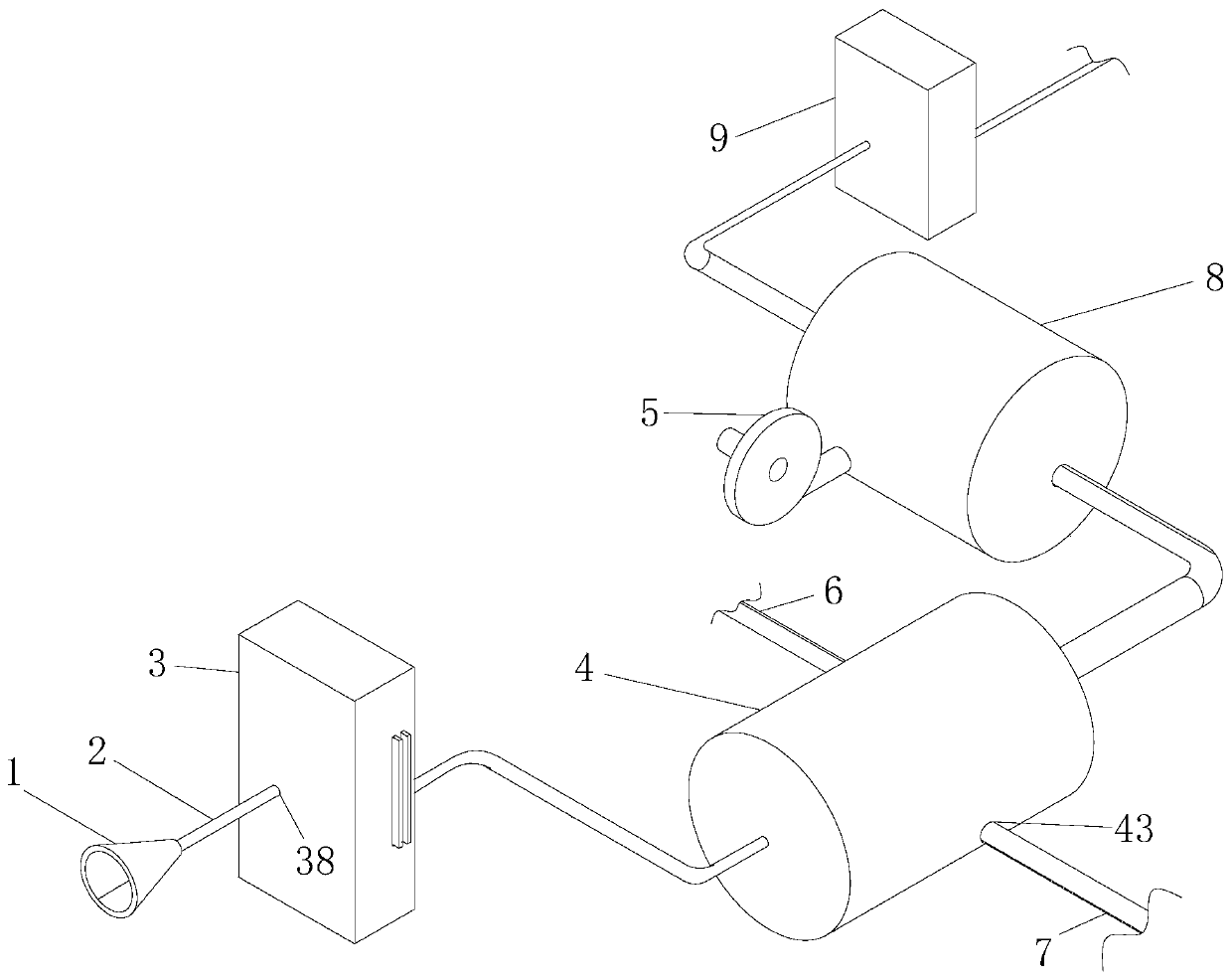

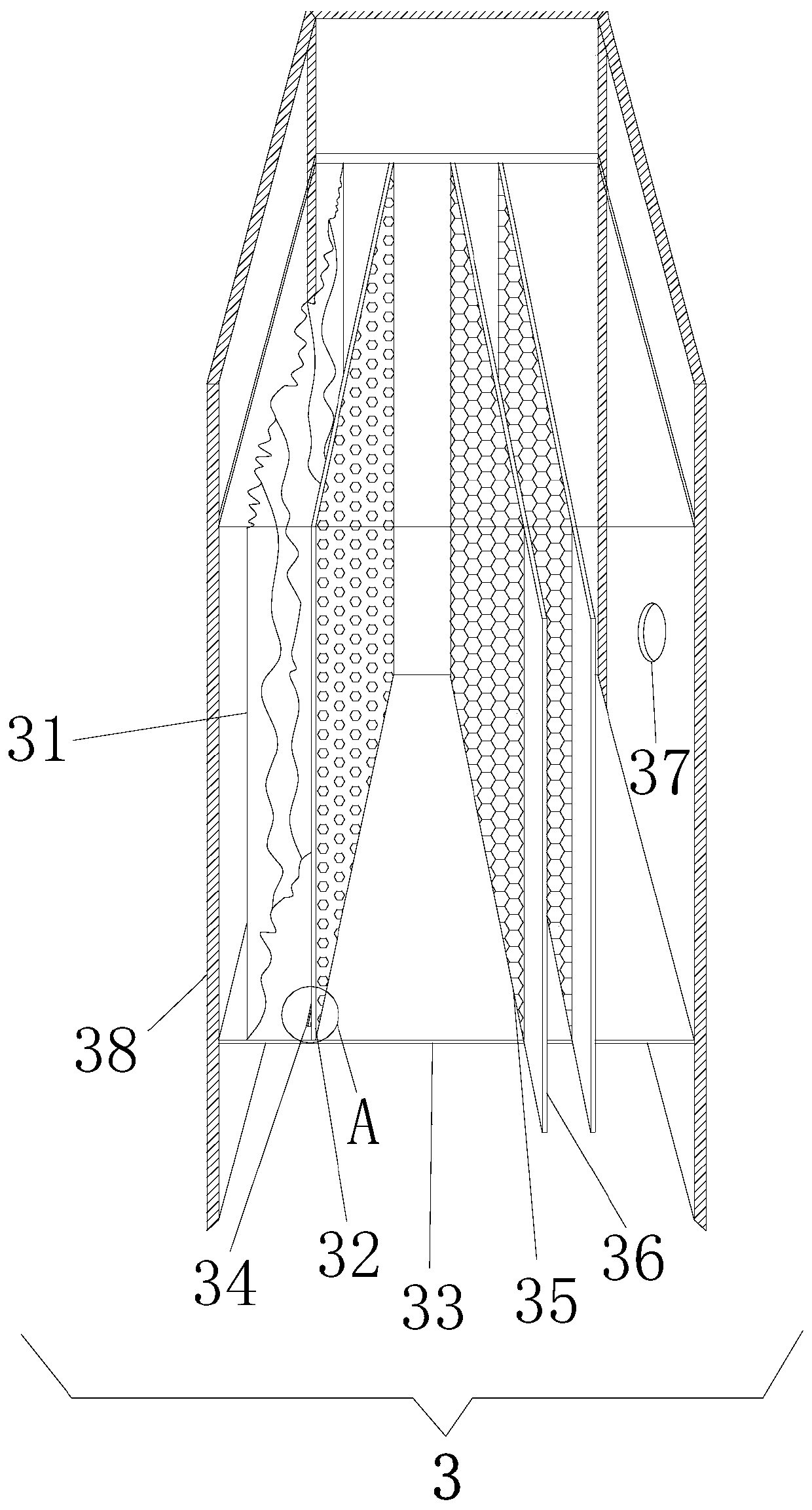

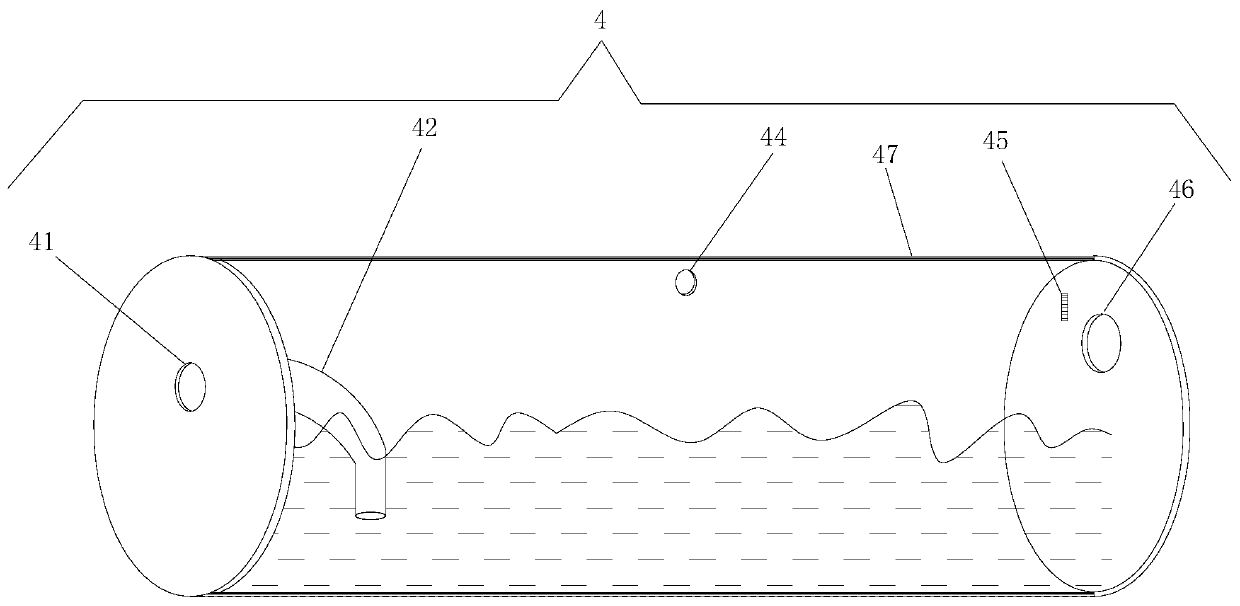

[0031] Such as Figure 1-5 As shown, the present invention provides a technical solution: an energy-saving and environment-friendly industrial waste gas treatment device, including a waste gas collection device 1, the waste gas collection device 1 is a hollow conical shape with a large front and a small rear, and the small mouth end of the waste gas collection device 1 passes through the pipe 2 The filter air inlet 38 on the filter box 39 is fixedly connected, and the filter air inlet 38 is provided with a filter air outlet 37 on the opposite side of the filter box 39, and the filter air inlet 38 and the filter air outlet 37 are in the filter box 39 The positions are relatively symmetrical, the pipeline 2 is an ordinary connecting pipeline, and the filter box 39 is a composition of the filter device 3. The filter box 39 is a hollow cuboid, and the inside of the filter box 39 is fixedly equipped with two fixed plates 33, and the fixed plate 33 four sides are all fixed on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com