Nuclear-grade water filter filter element filter material and production method thereof

A water filter and filter material technology, which is applied in the field of nuclear-grade water filter element filter material and its preparation, can solve the problems of poor water flow impact resistance and low filtration precision, and achieve strong water flow impact resistance and corrosion resistance Good performance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Nuclear grade water filter element filter material, including the base material and the non-woven fabric attached to the upper and lower surfaces of the base material, the base material and the non-woven fabric are soaked in water-based epoxy resin, sucked under negative pressure and then dried and bonded to each other. Together.

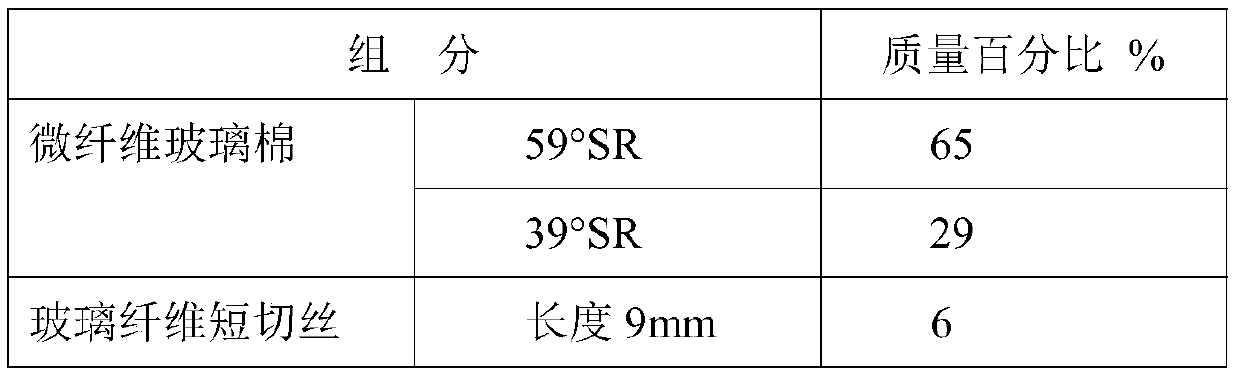

[0032] The composition of the base material is shown in Table 1:

[0033] The composition table of the base material of table 1 embodiment 1

[0034]

[0035] The chemical composition of microfiber glass wool is shown in Table 2:

[0036] The chemical composition table of the microfiber glass wool of table 2 embodiment 1

[0037] Element Mass proportion (%) SiO 2

60.5 Al 2 o 3

6.0 CaO 1.7 MgO 0.3 B 2 o 3

10.6 Na 2 o

8.6 K 2 o

2.9 BaO 5.0 ZnO 4.1

[0038] The preparation method of the nuclear grade water filter element filter material of embodime...

Embodiment 2

[0045] Nuclear-grade water filter element filter material, including the base material and the non-woven fabric attached to the upper and lower surfaces of the base material, the base material and the non-woven fabric are impregnated in water-based styrene-acrylic resin and water-based phenolic resin, then dried under negative pressure suction glued together.

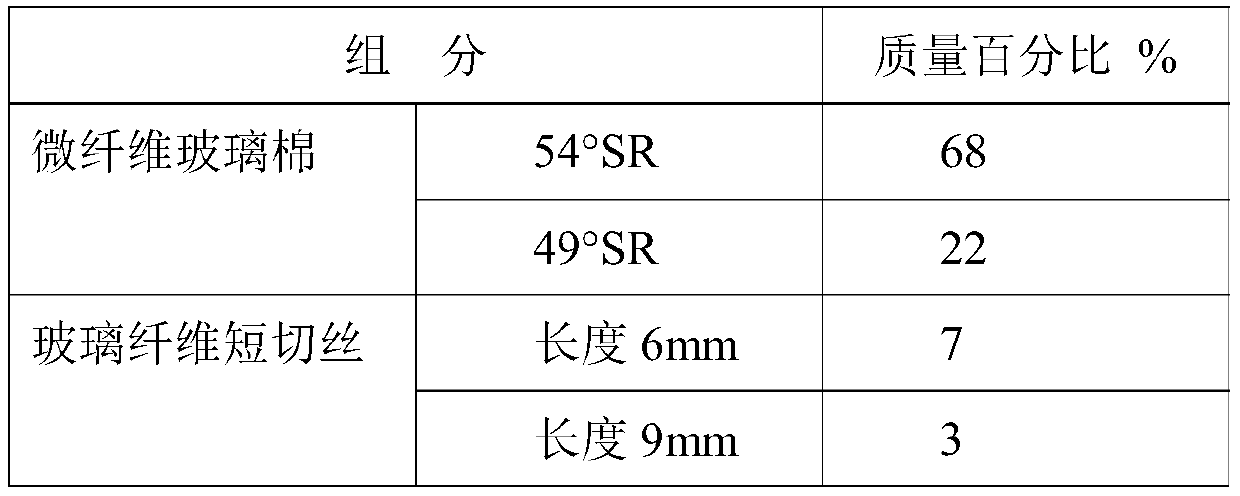

[0046] The composition of the base material is shown in Table 3:

[0047] The composition table of the base material of table 3 embodiment 2

[0048]

[0049] The chemical composition of microfiber glass wool is shown in Table 4:

[0050] The chemical composition table of the microfiber glass wool of table 4 embodiment 2

[0051] Element Mass proportion (%) SiO 2

59.2 Al 2 o 3

5.7 CaO 2.5 MgO 0.1 B 2 o 3

10.9 Na 2 o

10.3 K 2 o

1.9 BaO 4.8 ZnO 3.7

[0052] The preparation method of the nuclear grade water filter element fil...

Embodiment 3

[0059] Nuclear grade water filter element filter material, including the base material and the non-woven fabric attached to the upper and lower surfaces of the base material, the base material and the non-woven fabric are soaked in water-based acrylic resin, water-based polyurethane resin, dried and bonded after negative pressure suction. tied together.

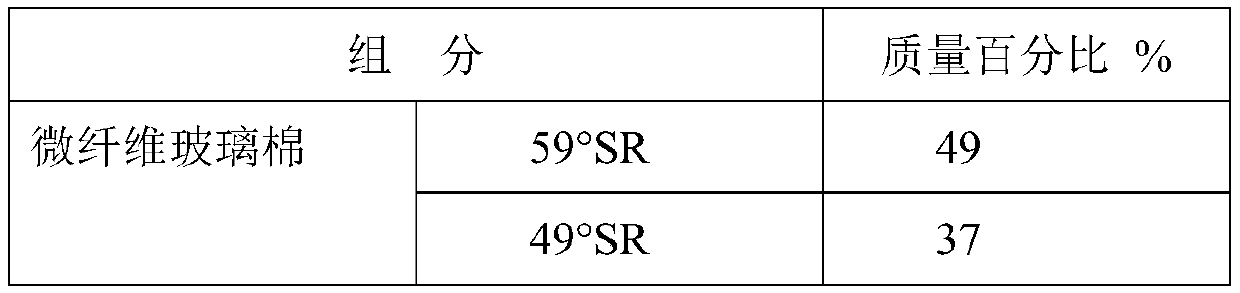

[0060] The composition of the base material is shown in Table 5:

[0061] The composition table of the base material of table 5 embodiment 3

[0062]

[0063]

[0064] The chemical composition of microfiber glass wool is shown in Table 6:

[0065] The chemical composition table of the microfiber glass wool of table 6 embodiment 3

[0066] Element Mass proportion (%) SiO 2

58.3 Al 2 o 3

4.8 CaO 2.8 MgO 2.3 B 2 o 3

13.3 Na 2 o

12.9 K 2 o

2.9 BaO 1.0 ZnO 1.5

[0067] The preparation method of the nuclear grade water filter eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com