Sorting screen surface material status monitoring system and control method thereof and combine harvester

A condition monitoring system, a technology of cleaning and screening, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve problems such as difficulties and the accumulation of grain exudates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

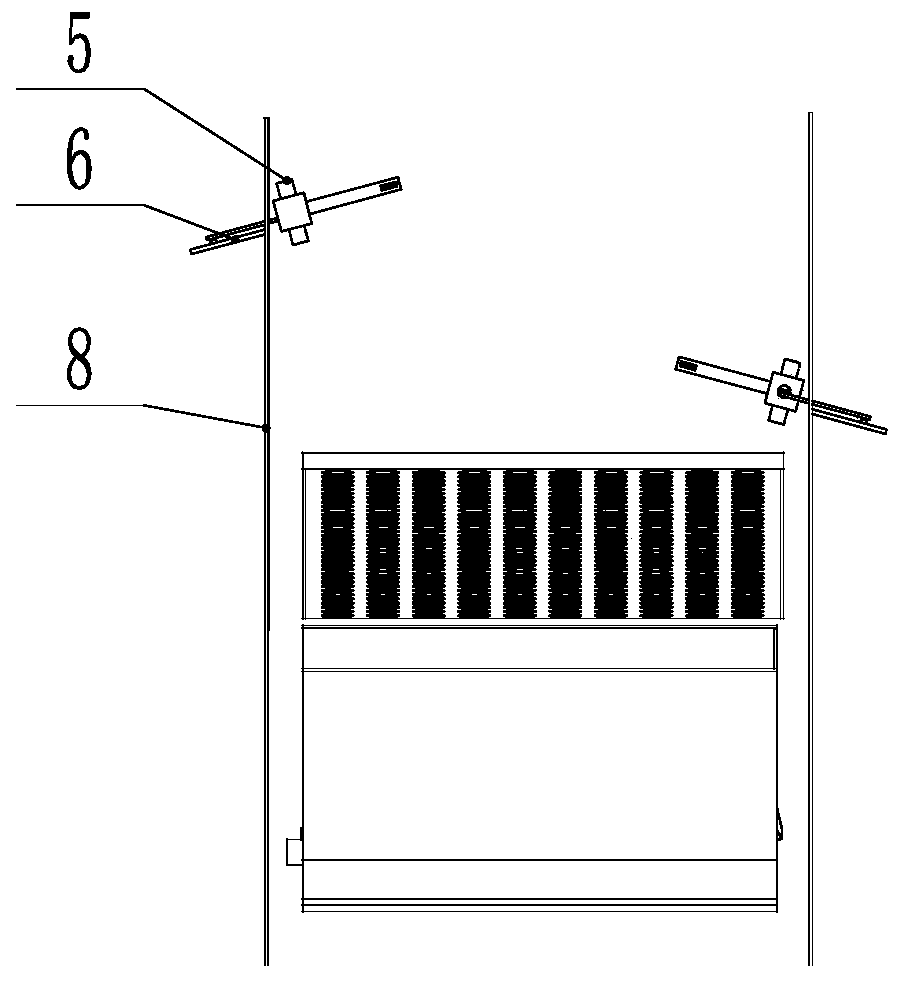

[0049] A wind speed monitoring device 6 is installed at the feed end and the waste outlet of the cleaning space, and the torque sensor 4 is installed on the grain auger shaft. The control method of embodiment 1 of the present invention, such as Figure 10 As shown, specifically:

[0050] Due to the different planting conditions and growth conditions of the fields where the combine harvester operates, it is impossible to set a unified standard to judge whether the airflow measured by the wind speed sensor 602 is within the normal range. The plots in a certain area are tested for cutting, and the torque value under normal working conditions and the airflow state measured by the wind speed sensors on both sides of the wall are respectively obtained, and the data are stored in the computer to obtain the torque standard library (X 1 ~X 2 ), through the sieve airflow standard library 1 (X 左min ~X 左max ) and sieve airflow standard library 2(X 右min ~X 右max ).

[0051] When work...

Embodiment 2

[0053] A wind speed monitoring device 6 is respectively installed at the feeding end and the miscellaneous outlet of the cleaning space, and the acceleration sensor 4' is adsorbed on the outside of the slide plate below the grain auger. The control method of embodiment 2 of the present invention, such as Figure 12 As shown, specifically:

[0054] Due to the different planting conditions and growth conditions of the fields where the combine harvester operates, it is impossible to set a unified standard to judge whether the airflow measured by the wind speed sensor 602 is within the normal range. Therefore, before the combine harvester starts formally, first Trial cutting is carried out on a certain area of land, and the impact vibration of the grains on the sliding plate under normal working conditions and the airflow state measured by the wind speed sensors on the two side walls are respectively obtained, and the data are stored in the computer to obtain the shock vibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com