Heating device and heating method inside refractory container

A heating device and heating method technology, which are applied in lighting and heating equipment, casting melt containers, furnace control devices, etc., can solve the problems of difficult to heat refractory container refractories, troublesome control, troublesome and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, a heating device and a heating method inside a refractory container according to an embodiment of the present invention will be specifically described based on the drawings. In addition, the heating device and heating method inside the refractory container of the present invention are not limited to the following embodiments, and can be appropriately changed and implemented within a range that does not change the gist of the invention.

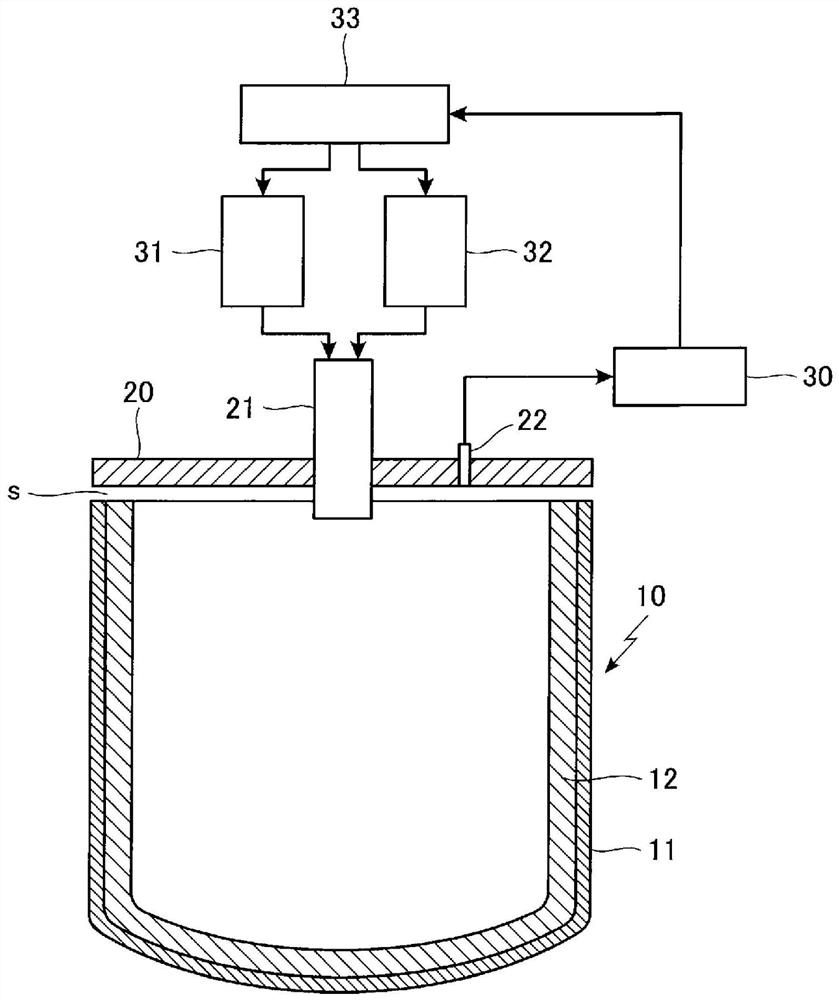

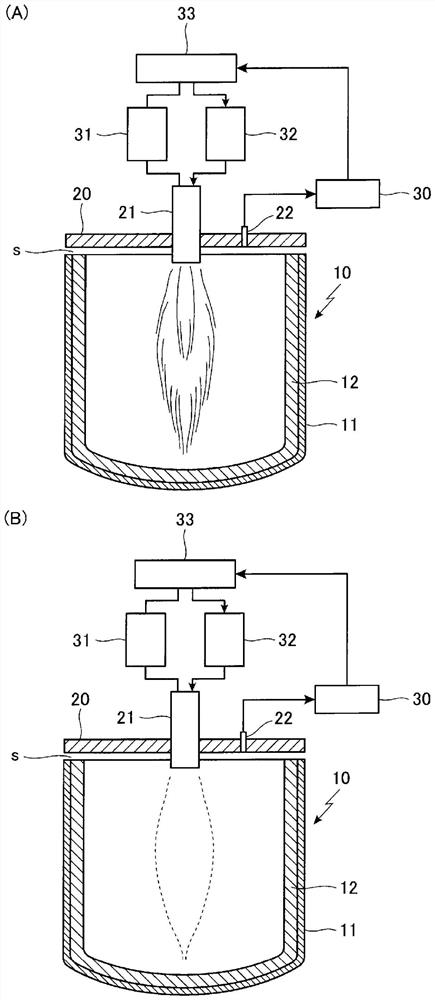

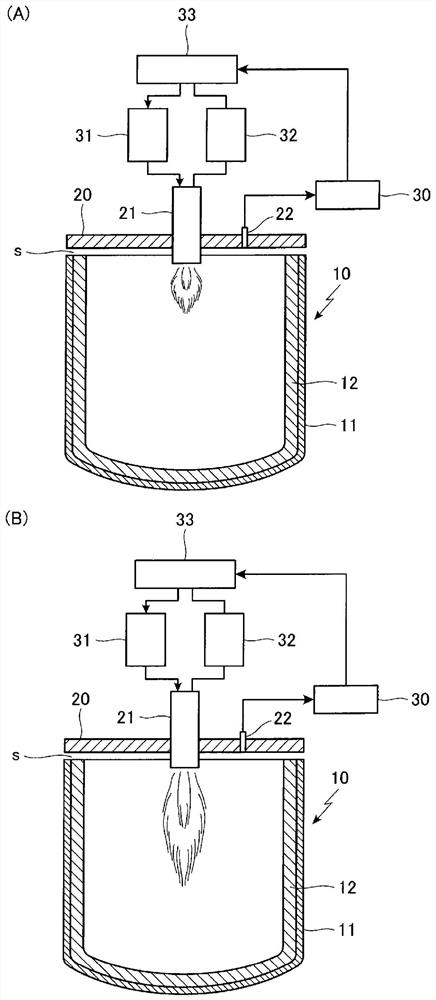

[0032] In the heating device inside the refractory container of this embodiment, if figure 1 , etc., as the refractory container 10, a pot-shaped member with an open upper surface, in which a refractory 12 is provided on the inner surface of an outer wall portion 11 made of steel or the like is used.

[0033] In addition, above the opening portion of the upper surface of the refractory container 10, a cover material 20 is arranged so as to cover it with a gap s (about 10 to 20 cm), and the refractory container is provided in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com