Circular comb with combing and alignment sections

A technology for circular combing and carding machine, applied in the direction of combing machine, fiber processing, textile and papermaking, etc., can solve the problems of unsatisfactory results, irregular carding machine, low carding effect, etc., to achieve increased efficiency The effect of contacting surfaces, optimizing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

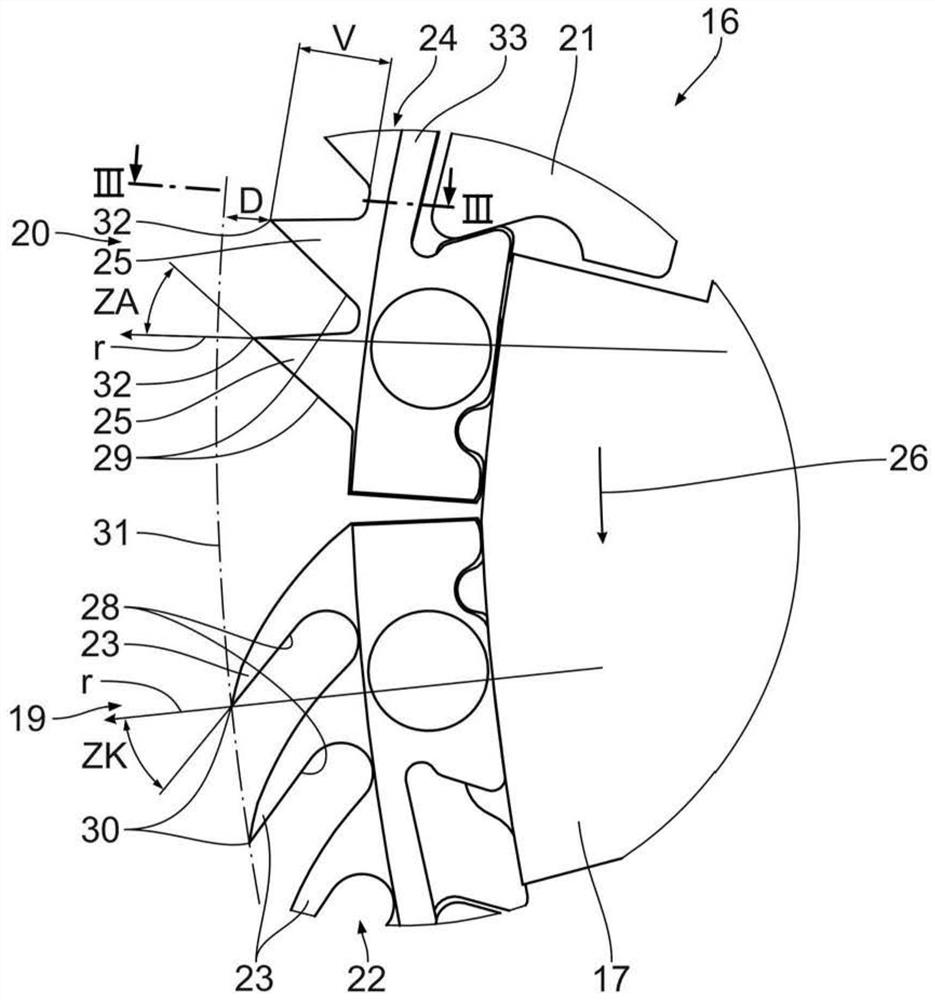

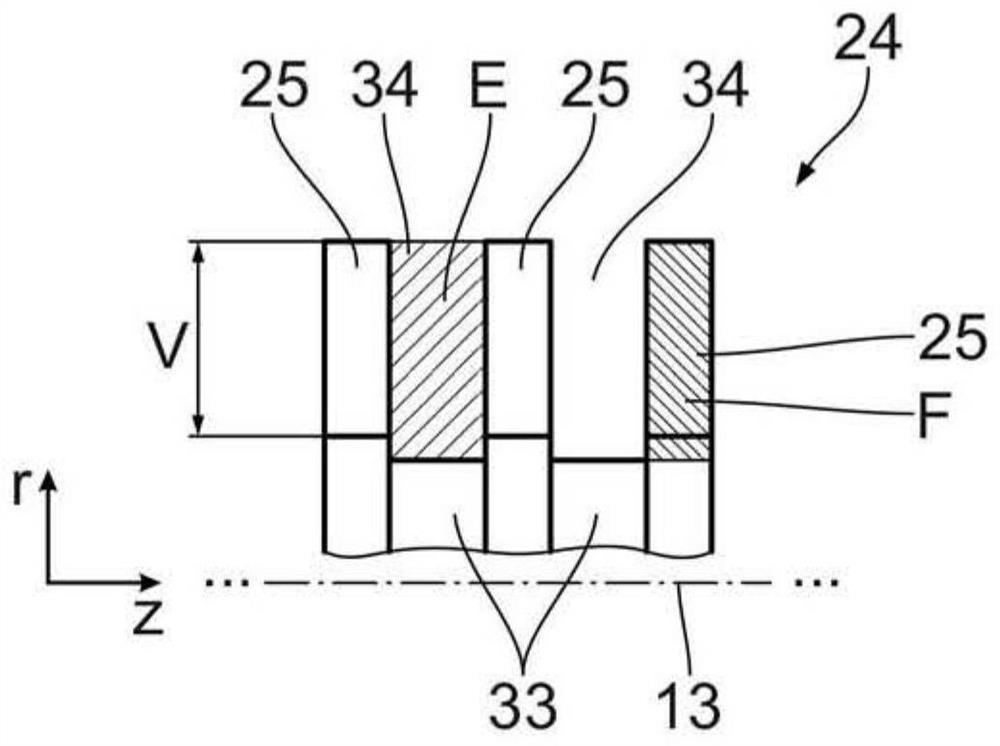

[0035] The corresponding parts are in Figures 1 to 7 Indicated with the same reference numerals. Details of the exemplary embodiments taken alone and explained in more detail hereinafter may also form part of the inventive or patentable subject matter.

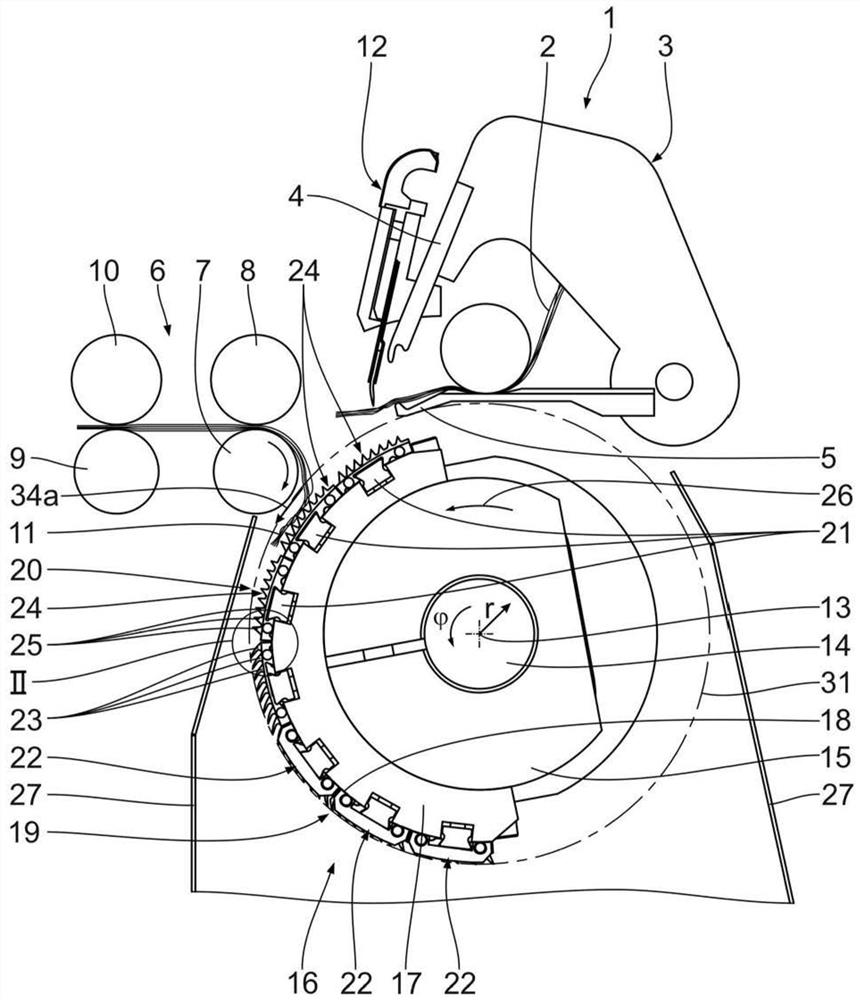

[0036] figure 1 An exemplary embodiment of a carding machine 1 for carding textile fibers 2 is shown, said figure showing only some components of this carding machine 1 . Therein, the card has a nipper assembly 3 with an upper nipper 4 and a lower nipper 5 for feeding the textile fibers 2 to be carded. The upper nipper 4 and the lower nipper 5 can be opened and closed during the carding cycle (=nipping cycle). exist figure 1 , shows the open state. The nipper assembly also performs a relative movement with respect to the other machine components of the carding machine 1 , in particular with respect to the separating unit 6 comprising stationary traction rollers 7 , 8 , 9 and 10 . The pulling rollers 7 to 10 are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com