Lens assembly method and system

An assembly method and assembly system technology, applied in installation, focusing devices, instruments, etc., can solve problems such as difficulty in obtaining a complete picture of the focusing circle, and achieve the effects of improving the automatic focusing effect, small assembly and assembly errors, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

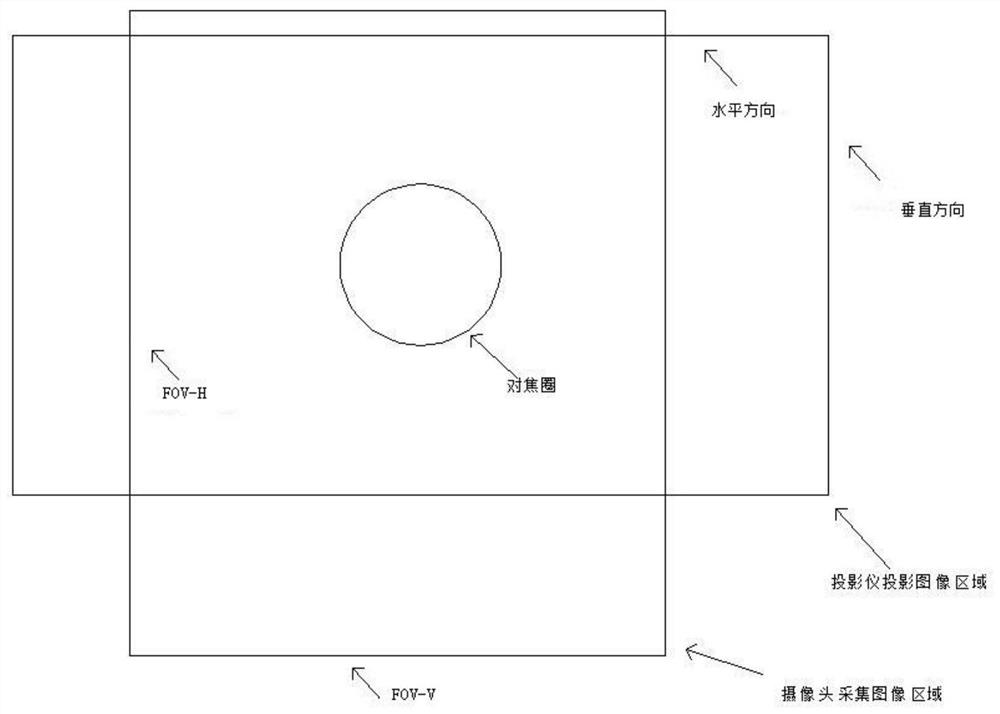

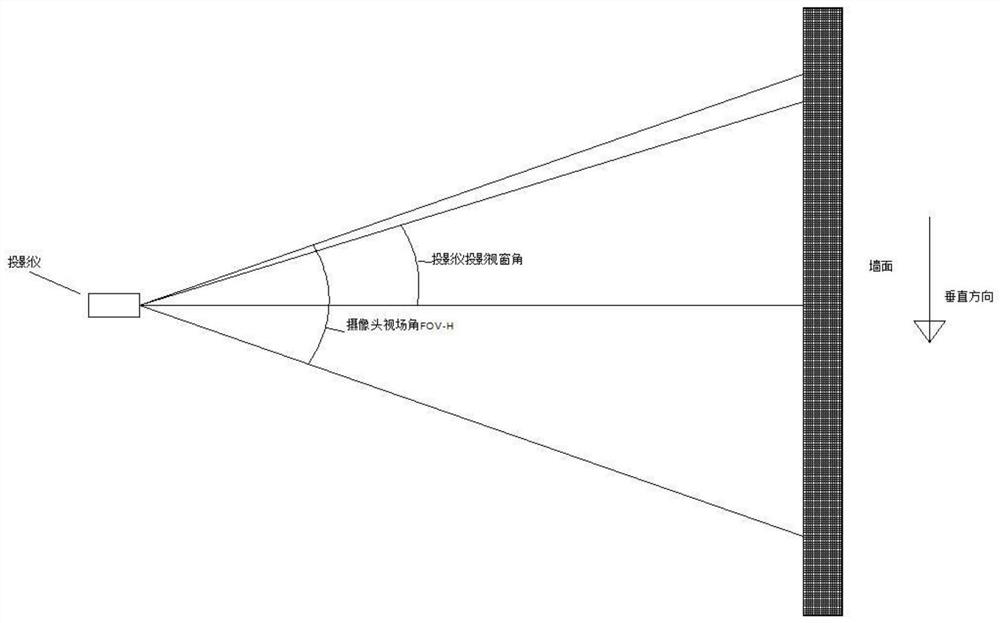

[0022] In the field of optics, FOV (Field of View) is the field of view, which refers to the maximum field of view that the lens can capture, including the diagonal field of view FOV-D, the horizontal field of view FOV-H and the vertical field of view FOV-V, its size relationship FOV-D>FOV-H>FOV-V. In order to adapt to the complete acquisition of the optical-mechanical focusing image during auto-focusing, and because the focusing circle has a high requirement for the vertical field of view, the PCB board needs to be rotated at a certain angle during assembly, which brings a certain error and assembly difficulty. Therefore, the solution provided in this embodiment can simply and quickly solve the above problems by converting the vertical viewing angle and the horizontal vertical viewing angle.

[0023] A lens assembly method, characterized in that: first determine the horizontal direction and vertical direction corresponding to the PCB board, and then determine the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com