Method for evaluating effects of pores with different dimensions on compressibility of total pore during pressurization

A technology of pore compressibility and compressibility, which is used in suspension and porous material analysis, measurement devices, scientific instruments, etc., and can solve the problems of quantitative evaluation of compressibility of pores of different sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

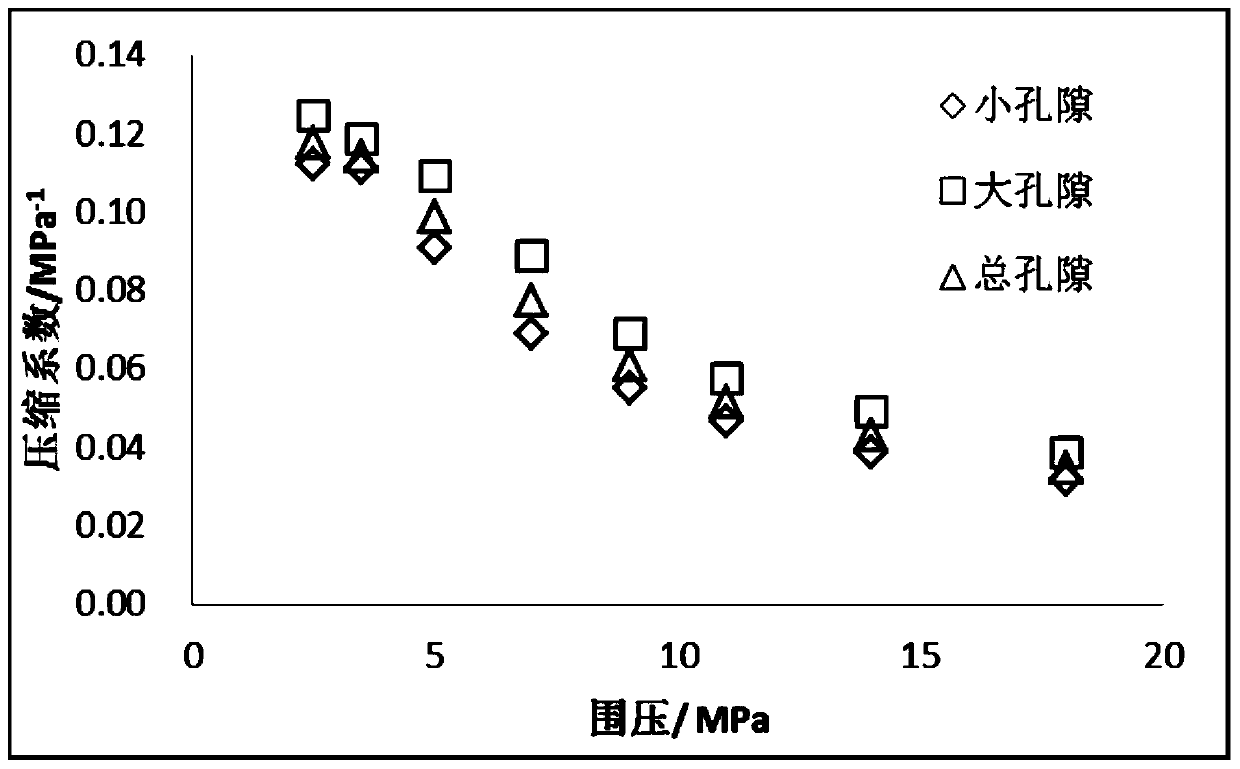

[0042] A method for quantitatively evaluating the influence of pores of different scales on the total pore compressibility during pressurization, comprising the following steps:

[0043] Step 1. Configure the simulated formation water for the experiment, and the salinity of the formation water is 30000mg / L;

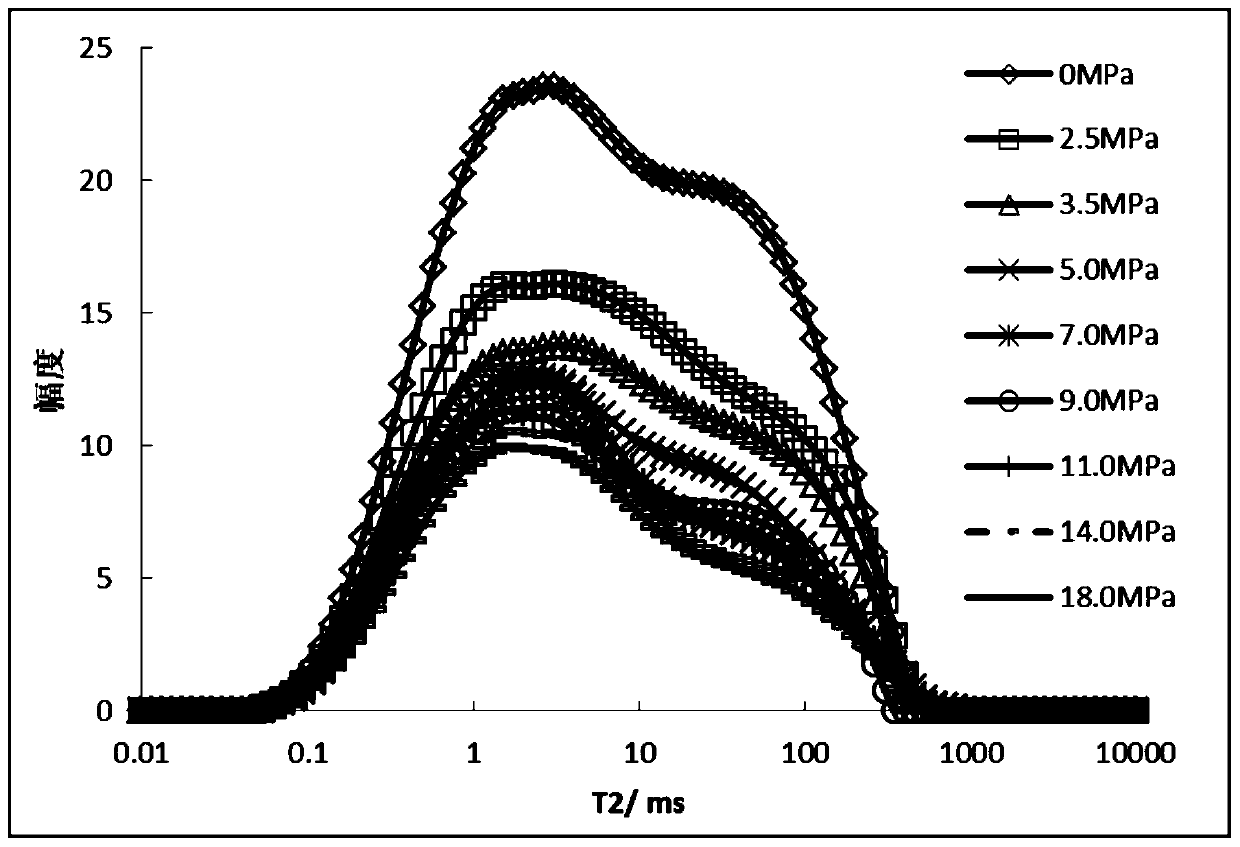

[0044] Step 2. Saturation of the core with a diameter of 2.5 cm and a length of 4 cm with simulated formation water, and placed it in a nuclear magnetic resonance high temperature and high pressure displacement system. The experimental temperature is 55 ° C, the confining pressure is 0 MPa, and the nuclear magnetic resonance T 2 Spectrum;

[0045] Step 3: The confining pressure is increased to 2.5MPa, and the simulated formation water is continuously injected into the core to 1 times the pore volume, and the nuclear magnetic resonance T is measured. 2 Spectrum;

[0046] Step 4: Increase the confining pressure to 3.5MPa, 5MPa, 7MPa, 9MPa, 11MPa, 14MPa, and 18MPa respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com