Prediction method and device for service life of high-speed railway gearbox casing structure

A technology of gear box and prediction method, applied in the field of fatigue strength, can solve problems such as difficult fatigue life, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

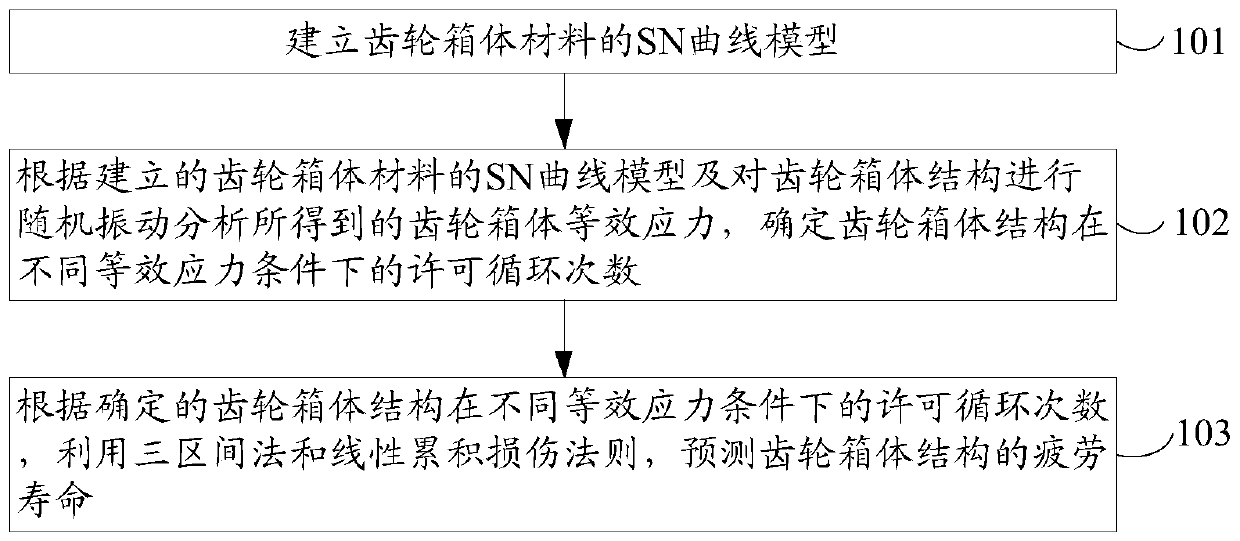

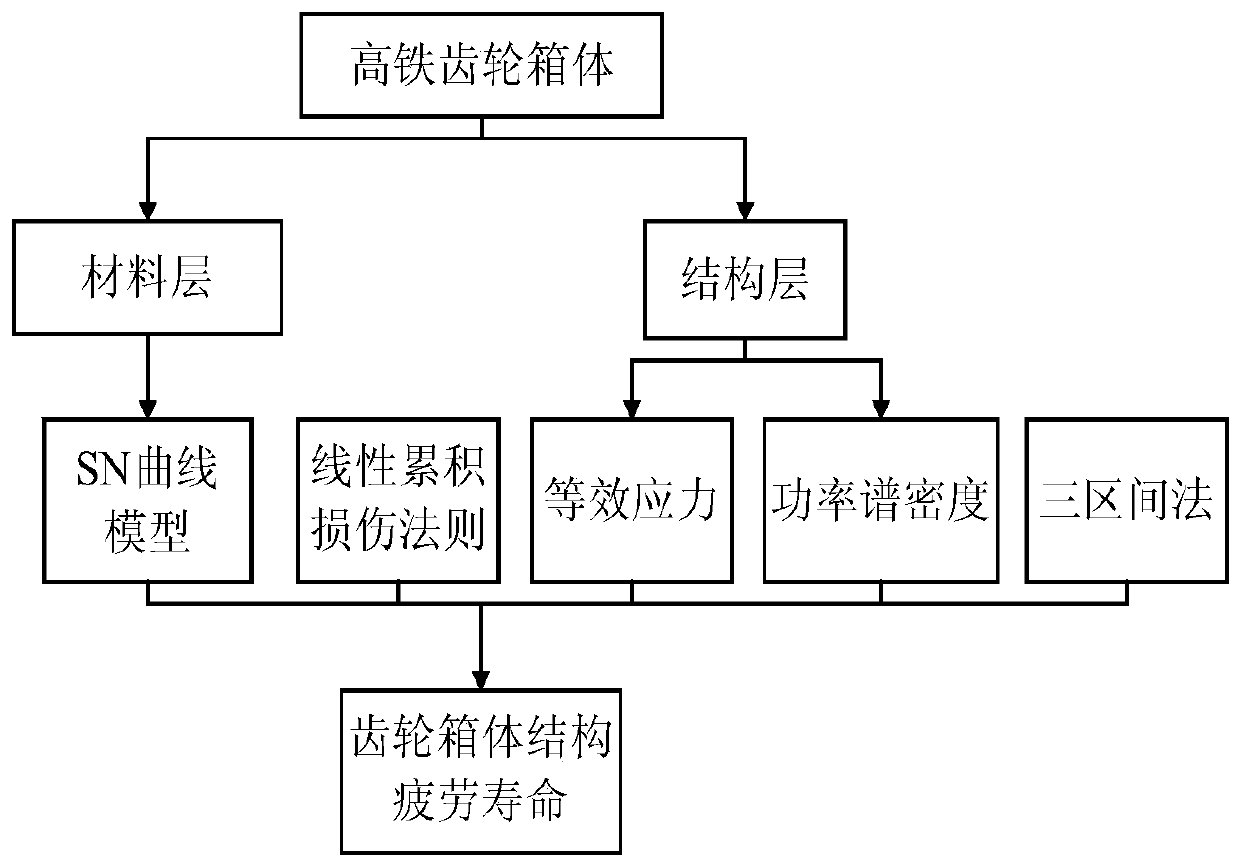

[0044] like figure 1 As shown, the prediction method for the structural life of the high-speed rail gear box provided by the embodiment of the present invention includes:

[0045] S101, establishing the SN curve model of the gear case material, wherein, N represents the allowable number of cycles of the gear case structure, and S represents the equivalent stress;

[0046] S102, according to the established SN curve model of the gear box material and the equivalent stress of the gear box obtained by random vibration analysis of the gear box structure, determine the allowable number of cycles of the gear box structure under different equivalent stress conditions;

[0047] S103. Predict the fatigue life of the gearbox structure by using the three-interval method and the linear cumulative damage rule according to the determined permissible cycle times of the gearbox structure under different equivalent stress conditions.

[0048]The method for predicting the life of the high-spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com