Reflective multi-core circular fiber optic shape sensor

A multi-core optical fiber and reflective technology, which is applied in the field of reflective multi-core circularly connected shape sensors, can solve the problems of real-time sensing and other problems, and achieve the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

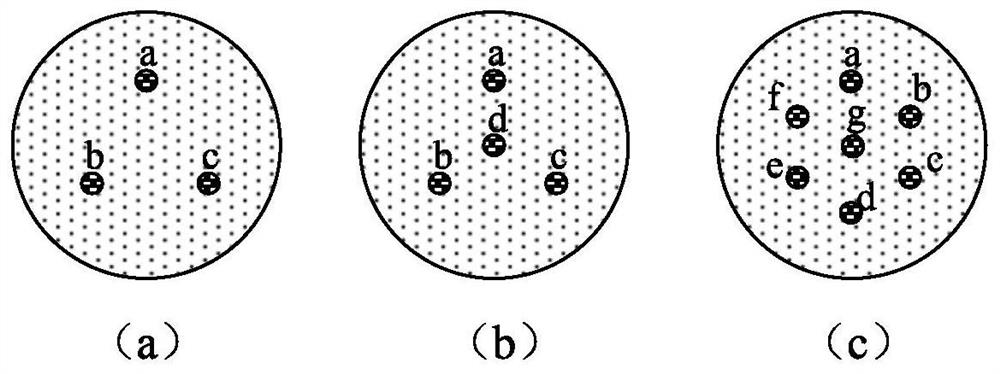

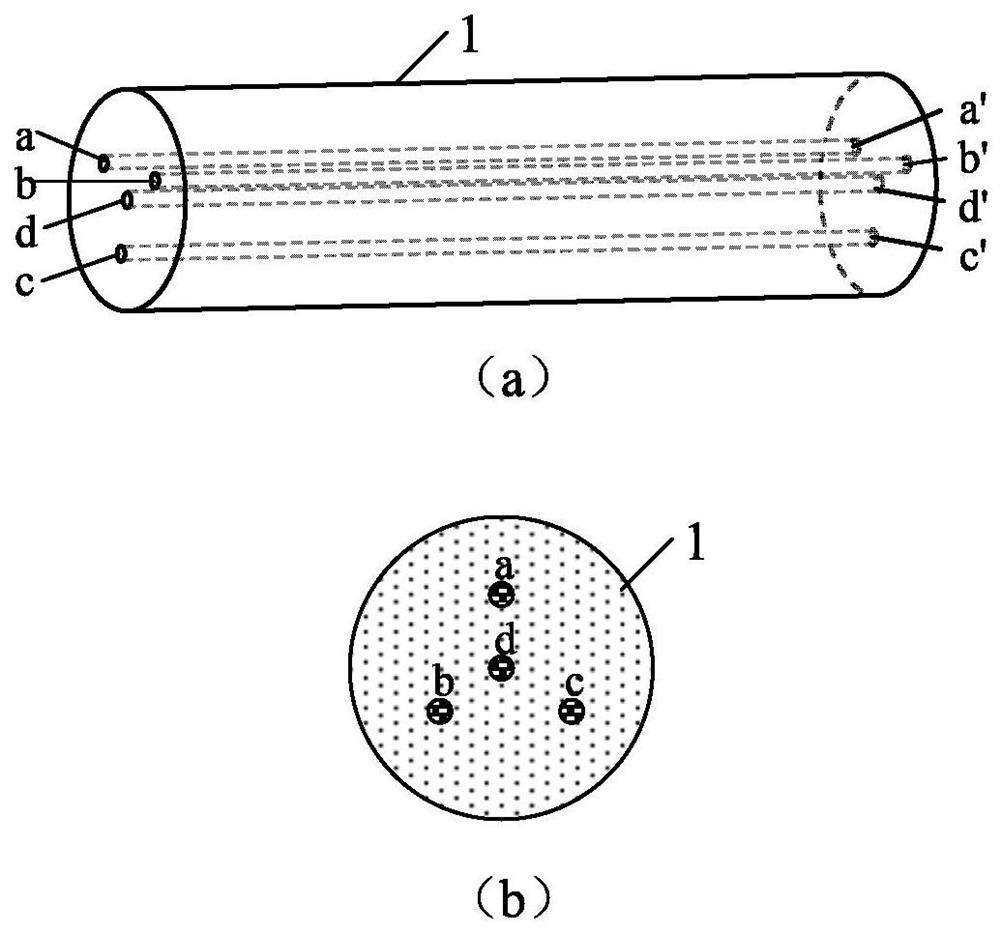

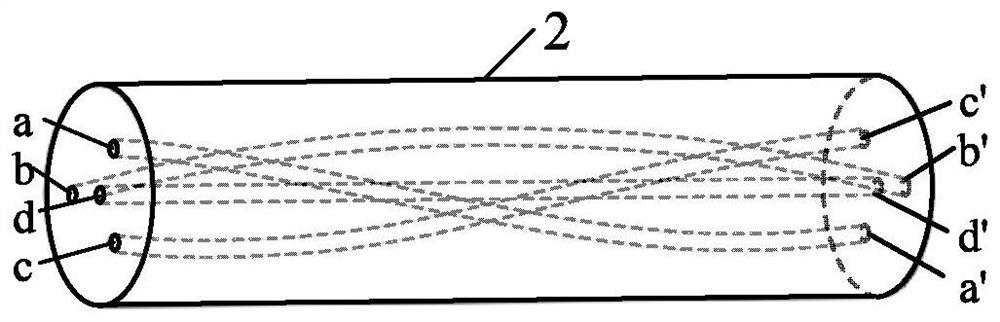

[0032] In order to obtain 3D shape sensing, distributed bending and torsional sensing are required simultaneously. On multi-core fiber, this goal can be achieved by using Brillouin Optical Time Domain Analysis Technology (BOTDA). To this end, the invention provides a reflective multi-core circular fiber optic shape sensor used in a dynamic BOTDA system. The sensor uses multi-core optical fiber. This kind of multi-core fiber can have many forms: (1) a multi-core fiber with multiple cores arranged in a circle and the number of cores N≥3, such as figure 1 (a) The three-core optical fiber shown; (2) A multi-core optical fiber with an intermediate core and three or more circumferentially distributed peripheral cores, such as figure 1 Four-core optical fiber and seven-core optical fiber shown in (b) and (c); (3) spiral multi-core optical fiber in which peripheral cores are helically distributed around the middle core. For convenience, the following content and drawings use a four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com