Centralized water gate group monitoring device

A monitoring device, a centralized technology, applied in valve devices, measuring devices, lubrication indicating devices, etc., can solve the problems of inability to monitor dynamic video of sluice gates, inability to monitor water level rising speed in advance, and inability to achieve preventive management in advance, etc. The effect of monitoring range, reducing monitoring blind spot, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

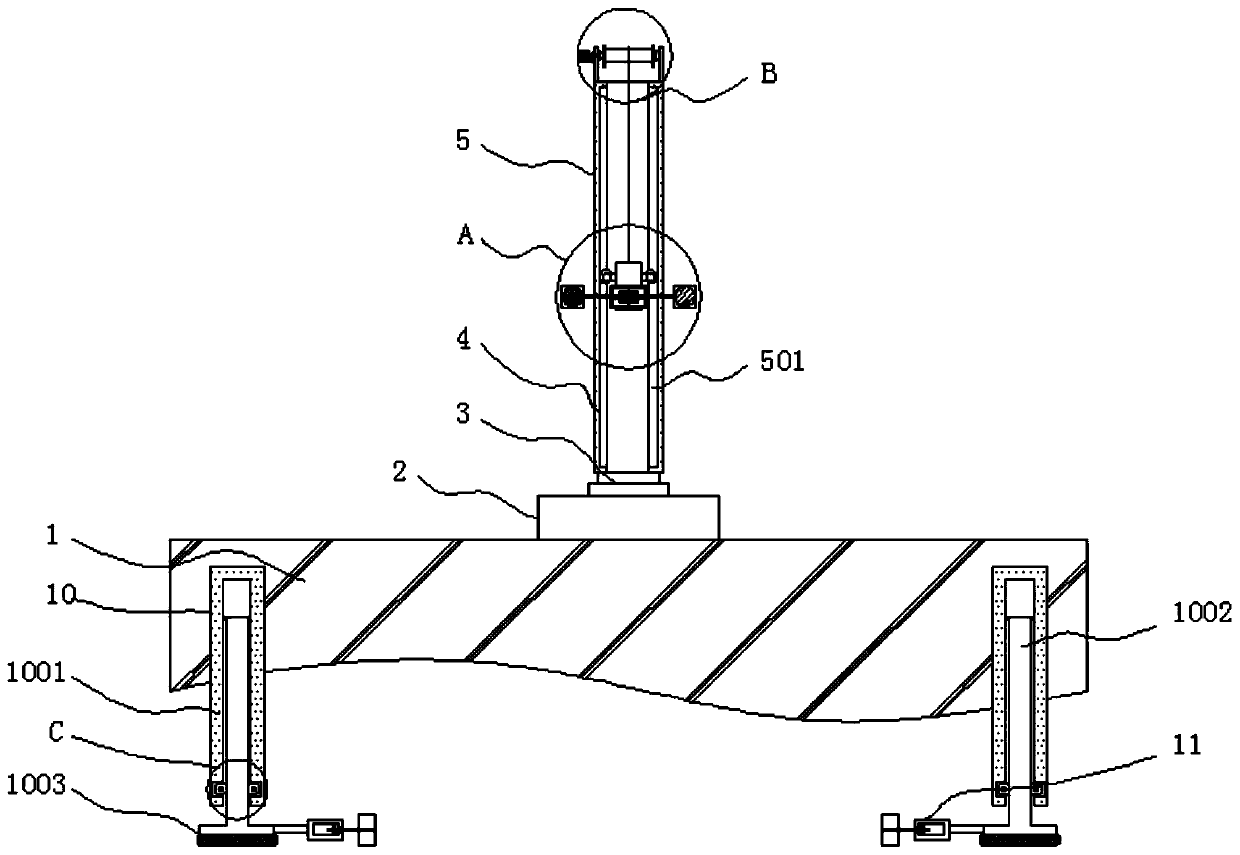

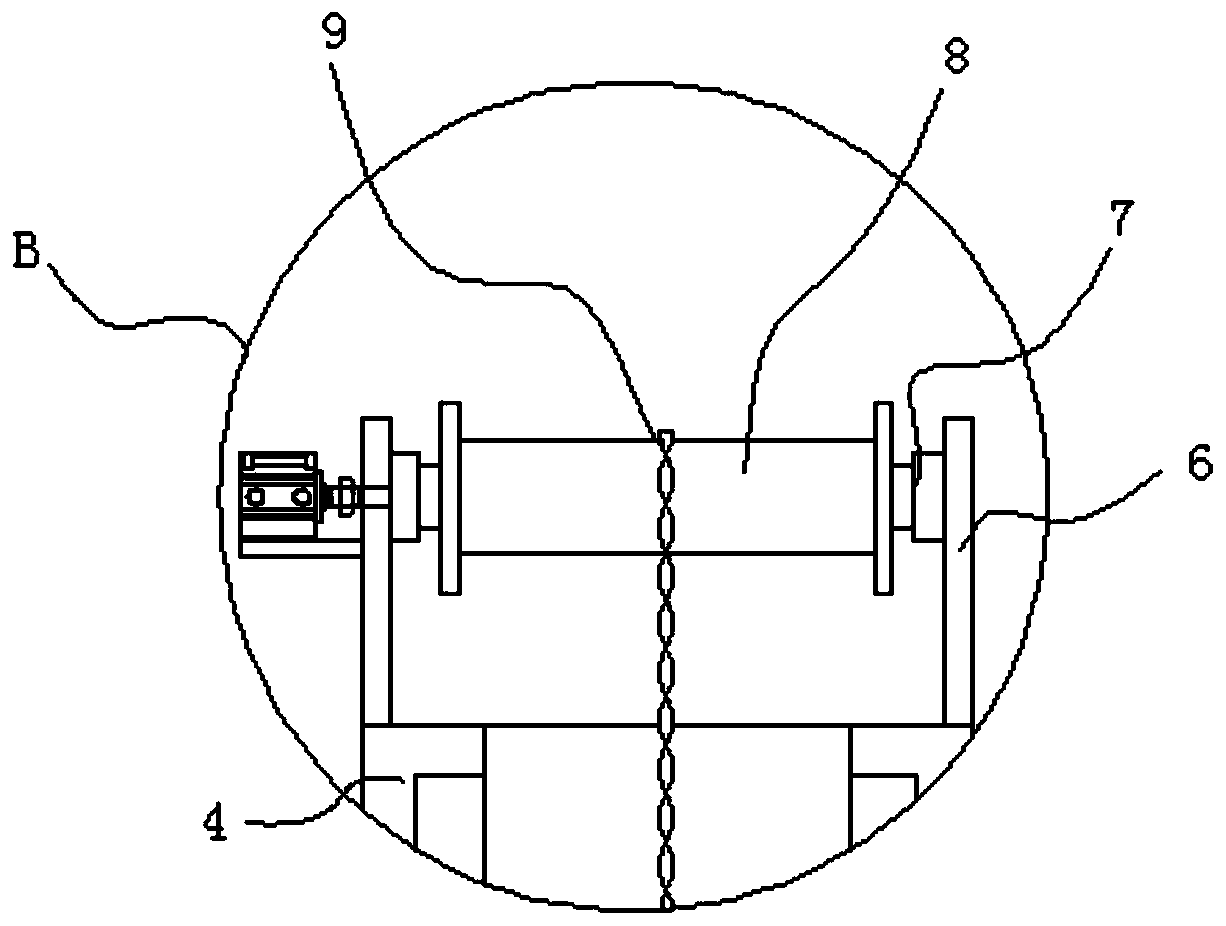

[0042] see Figure 1-7, a centralized sluice group monitoring device, including a sluice main body 1, a water level rising speed monitoring mechanism 10 and a self-cleaning mechanism 12, a control box 2 is arranged on the upper end of the sluice main body 1, and a first rotating shaft 3 is arranged on the upper end of the control box 2, The upper end of the first rotating shaft 3 is inlaid with a support tube 4, and the front of the support tube 4 is connected with a video monitoring mechanism 5, and the upper end of the support tube 4 is equipped with a support frame 6, and the inner two sides of the support frame 6 are fixed with a second The rotating shaft 7 and the end of the second rotating shaft 7 close to the centerline of the support frame 6 are provided with a reel 8, and the front of the reel 8 is provided with a steel chain 9, and the water level rising speed monitoring mechanism 10 is embedded in the front of the sluice main body 1 On both sides, and the end of the...

Embodiment 2

[0044] see figure 1 , the support tube 4 constitutes a rotating structure through the first rotating shaft 3 and the control box 2, and the control box 2 is fixedly connected to the main body 1 of the sluice, the supporting tube 4 can rotate along the first rotating shaft 3, then it can take its The monitoring probe 506 at the upper end rotates horizontally, so that the surroundings of the water gate can be monitored in a large area, the monitoring range of the water gate can be increased, and the monitoring blind area can be reduced.

Embodiment 3

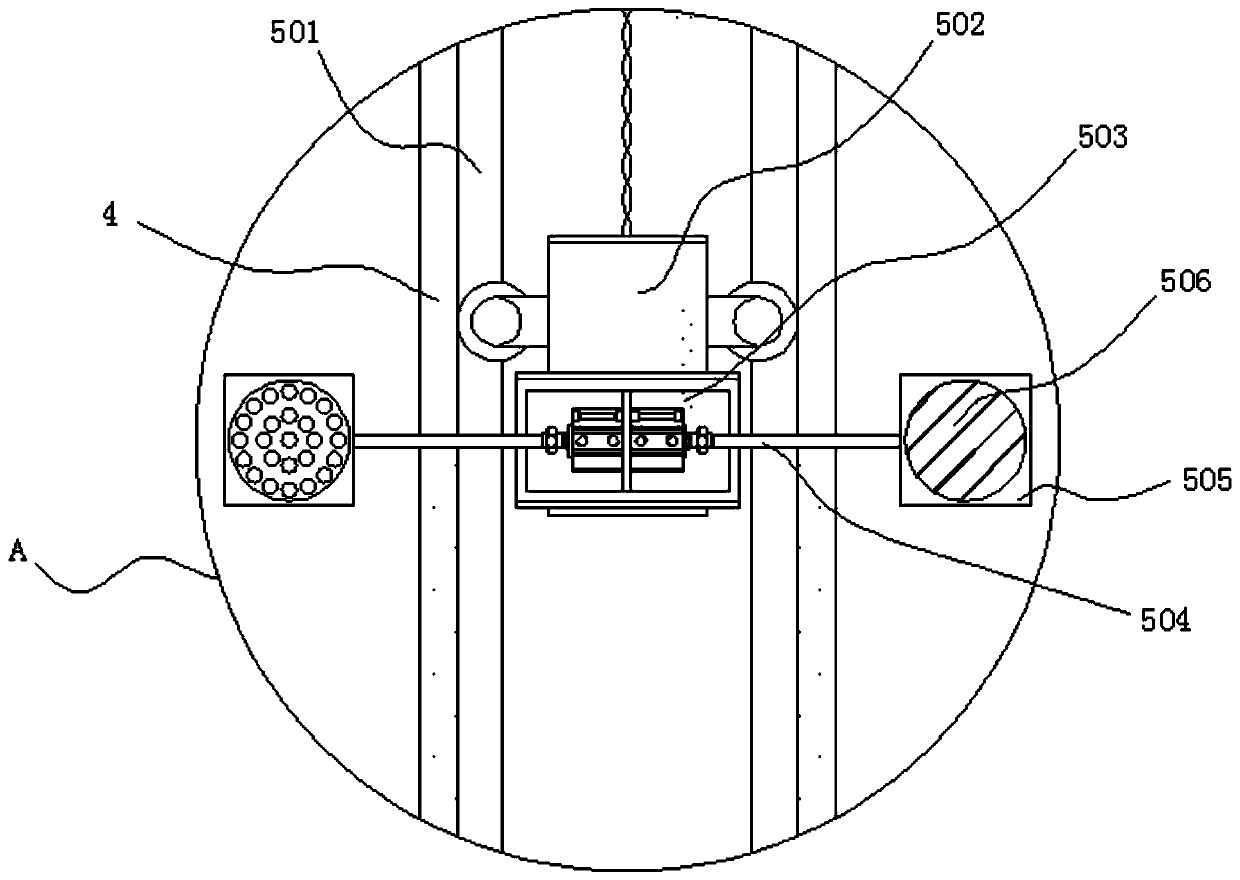

[0046] see figure 1 with 2 , the inside of the video monitoring mechanism 5 includes a chute 501, and an integral connection is formed between the chute 501 and the inner wall of the support tube 4 by injection molding, the inside of the support tube 4 is provided with a sliding frame 502, and the front side of the sliding frame 502 is welded There is a first chassis 503, and drive shafts 504 are arranged on both sides of the interior of the first chassis 503, and an installation box 505 is inlaid on the end of the drive shaft 504 away from the center line of the first chassis 503, and a monitoring probe 506 is connected inside the installation box 505, Sliding frame 502 is connected with steel chain 9, is movable connection between cylinder 1005 and movable plate 1002, and is sliding connection between movable plate 1002 and fixed plate 1001, and cylinder 1005 is symmetrical about the central line of fixed plate 1001, and its cylinder 1005 The rotating structure is formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com