A multi-stage vane compressor structure with independent rotation and sequential acceleration without stationary vanes

An independent rotating, compressor technology, applied in the field of fluid compressors, can solve the problems of surge, short service life, energy consumption, etc., and achieve the effect of preventing surge, reducing equipment size, and eliminating surge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

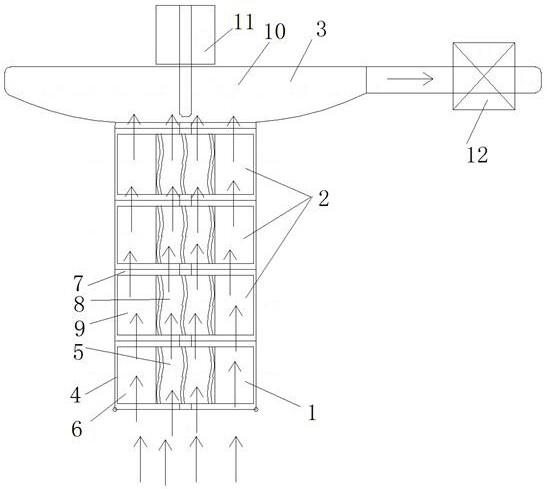

[0018] Such as figure 1 As shown, the present invention is a multi-stage non-stationary vane independent rotation and sequentially accelerated vane compressor structure, including a first-stage compressor 1, a plurality of intermediate compressors 2 and last-stage compressors 3 that are sequentially stacked and connected, and the first-stage compressor 1 and the middle compressor 2 have the same structure, the air inlet of the middle compressor 2 is sealed and connected with the air outlet of the first-stage compressor 1, and the air outlet of the middle compressor 2 is sealed and connected with the air inlet of the last-stage compressor 3; the first-stage compressor 1 Including the first-stage casing 4, the first-stage motor 5 is arranged on the central axis of the first-stage casing 4, and the first-stage impeller 6 is arranged around the first-stage motor 5, and the first-stage impeller 6 is connected with the rotating end of the first-stage motor 5; the middle compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com