Long well section sectional gravel filling tubular column for horizontal well and technique of long well section sectional gravel packing tubular column

A technology for gravel packing and horizontal wells, which is applied in the direction of boreholes/well components, earthwork drilling and production, and production fluids, etc. It can solve the problems of poor development effect of horizontal wells, low gravel packing efficiency, and construction failure, etc., to improve gravel packing The effect of improving efficiency, shortening construction waiting time, and avoiding filling failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention will be described in detail below in conjunction with preferred embodiments.

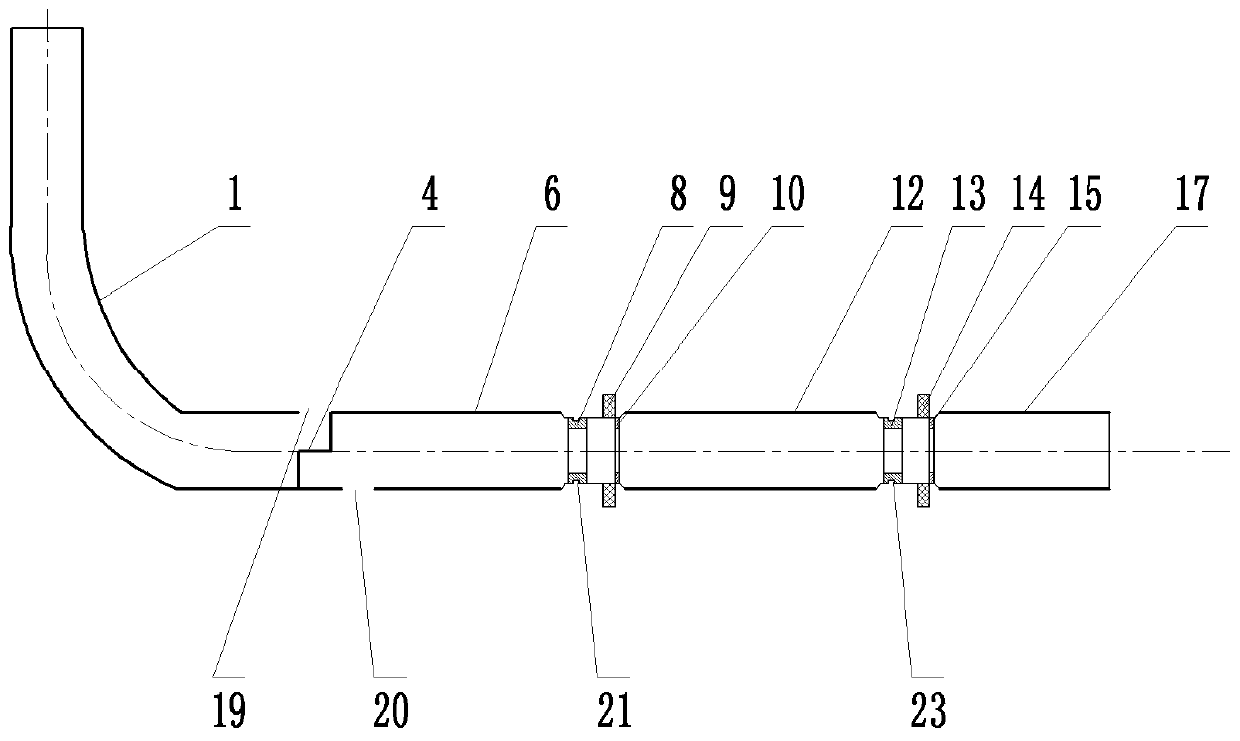

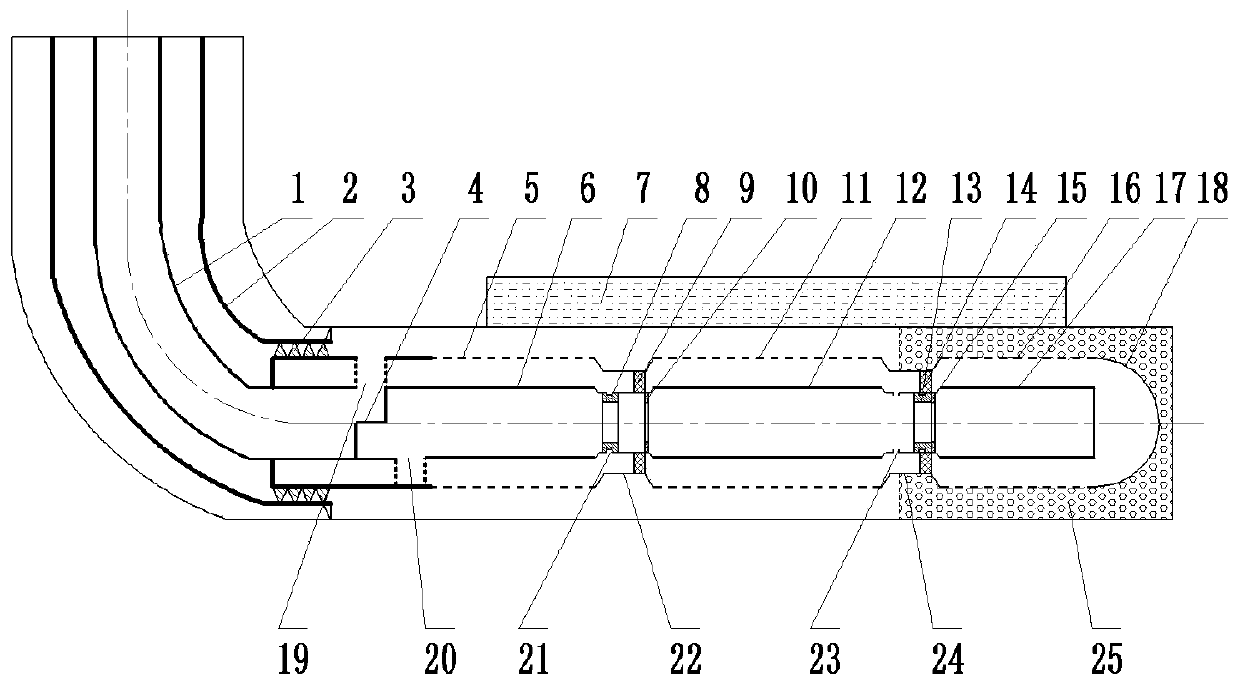

[0027] see attached figure 1 , 2 , the present invention adopts a segmented gravel-packing pipe string for a long section of a horizontal well, including an inner pipe string and an outer pipe string, and the inner pipe string includes a drill string 1 , a flow-around pipe string connected sequentially from left to right Device 4, upper flushing pipe 6, middle flushing pipe 12, and lower flushing pipe 17, the front end and rear end of the middle flushing pipe are respectively connected to the upper flushing pipe 6 and the lower flushing pipe 17 through the filling valve mechanism, and the filling valve mechanism Including the outer sleeve 13, the opening valve core 8 and the positioning ring piece 10, the outer sleeve is screwed between the upper flushing pipe 6 and the middle flushing pipe 12, and the outer sleeve is screwed between the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com