Large snow and ice removal operation mechanism with more firm combination of perching knife

A technology of operating mechanism and shovel blade, which is applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of high production, preparation and maintenance costs, difficulty in widespread application, low bonding strength of shovel edge and shovel edge buffer guard, etc. problems, to achieve the effect of uncomplicated overall structure, low production, preparation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

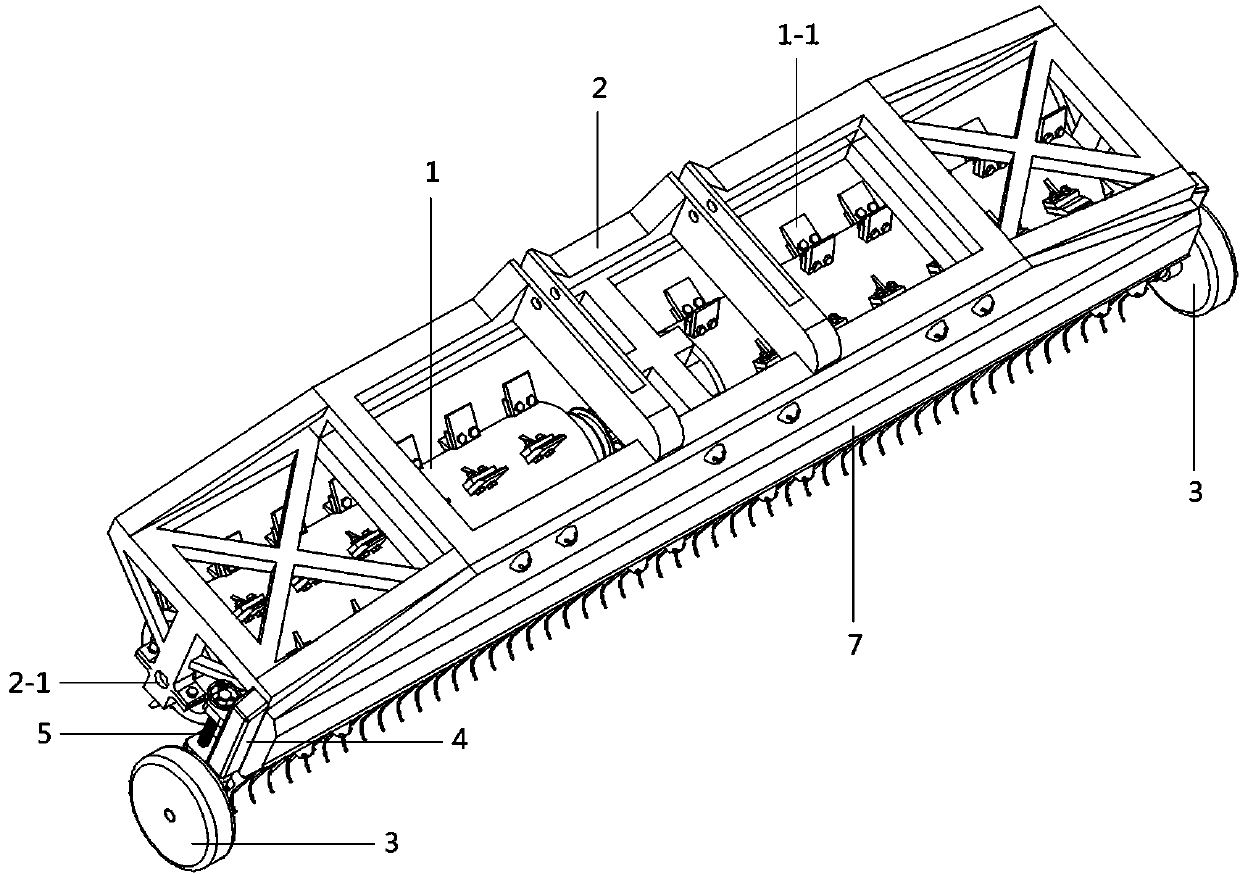

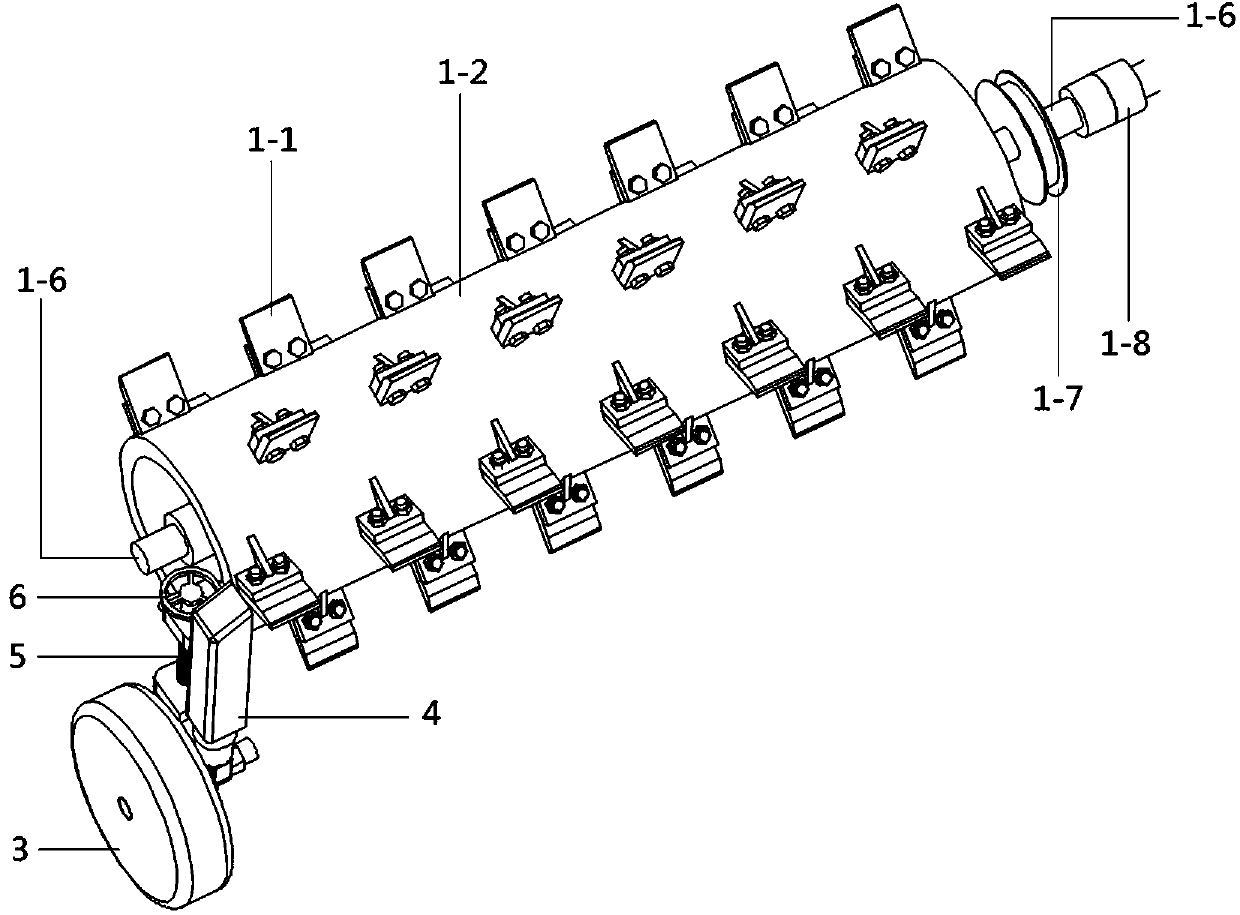

[0056] as attached figure 1 As shown, the present invention specifically relates to a large-scale snow and ice removal operation mechanism with a more firm blade combination, and its composition includes a snow and ice removal operation mechanism assembly 1, a mounting bracket assembly 2, a support wheel mounting bracket 4, and a blade height adjustment wire Bar 5, handwheel 6, pine snow ice comb 7 etc., its main structure and function are as follows.

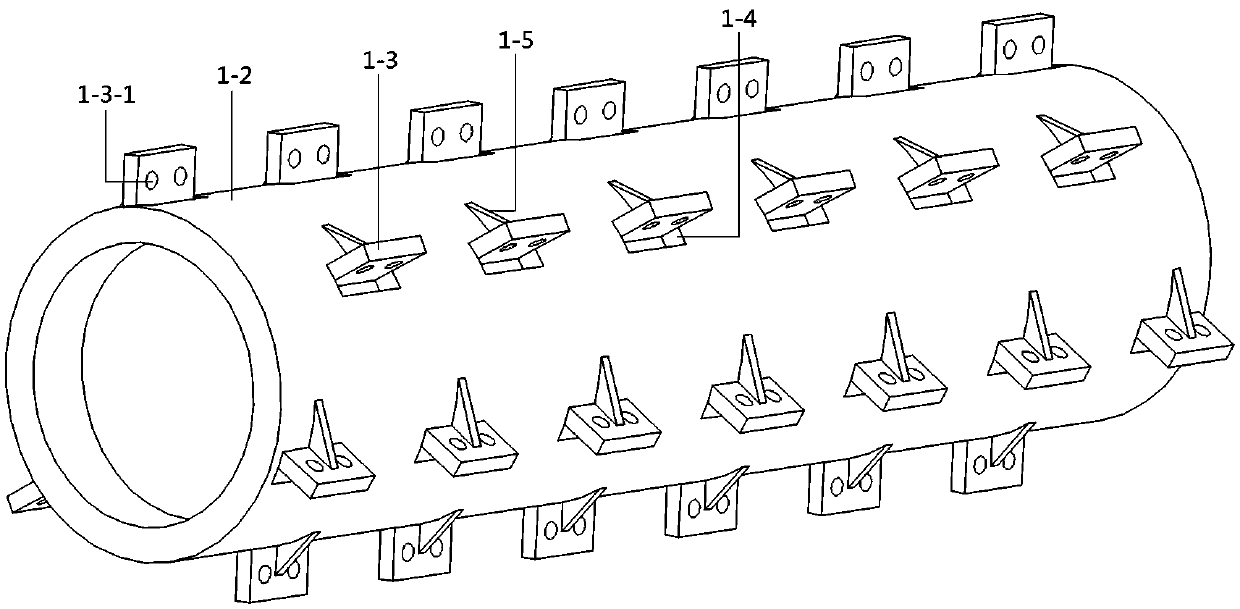

[0057] Such as figure 1 , figure 2 with image 3 As shown, the shovel 1-1 is installed on the connecting plate 1-3 by bolt fastening, the shovel, the lower end of the shovel 1-1 is inserted into the shovel positioning groove 1-4, the shovel positioning groove 1 -4 has a depth of 16 mm, and a reinforcing rib plate 1-5 is provided to enhance the impact load resistance of the blade 1-1 and the connecting plate 1-3. Since the drum 1-2, the connecting plate 1-3 and the blade positioning groove 1-4 are integrally cast, the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com