Transition primer composition

A technology of composition and primer, applied in the direction of primer and coating, can solve the problem of no adhesion, etc., and achieve the effect of moderate film thickness, good adhesion and good bridging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] Correspondingly, the embodiment of the present invention also provides the preparation method of above-mentioned transition primer composition, comprises the following steps:

[0019] S01, provide vinyl chloride resin and solvent according to the above formula;

[0020] S02, dissolving the vinyl acetate resin in the solvent to obtain.

[0021] As a preferred embodiment, after step S02, add the defoamer and leveling agent, and continue stirring and mixing until the components are fully mixed.

Embodiment 1

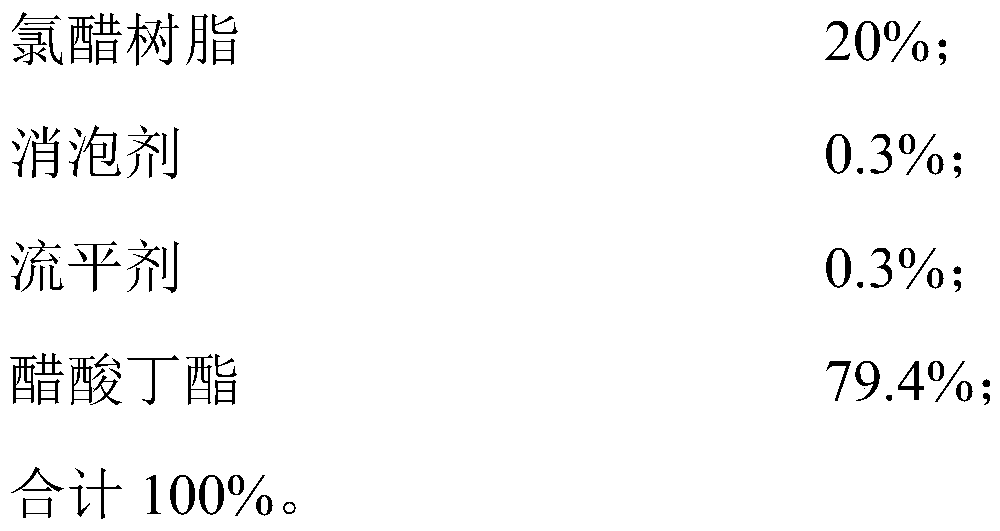

[0024] The present embodiment has prepared a kind of transition primer composition, comprises following weight percentage composition:

[0025]

[0026] Among them, the above-mentioned vinyl resin is selected as A-251 of Lihua Synthetic Resin; the above-mentioned defoamer is selected as BYK-141 of BYK Additives; the above-mentioned leveling agent is selected as BYK-331 of BYK Additives.

[0027] During the preparation, weigh the raw materials according to the above formula, then dissolve the vinyl acetate resin and additives in the solvent, stir and mix well to obtain the product.

[0028] When in use, the transition primer composition is directly sprayed on the PVC substrate with imitation wood grain effect. After about 30 minutes, the solvent is completely evaporated, and then the PU topcoat is continued to be sprayed on the paint film. After drying for 48 hours, Test the adhesion according to the national standard GB / T 9286-1998, and the adhesion can reach level 0 or abo...

Embodiment 2

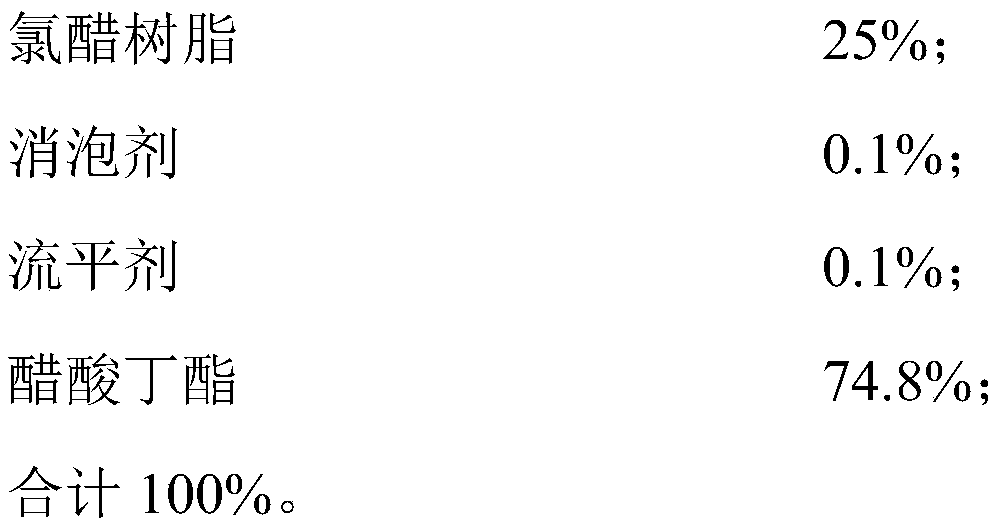

[0030] The present embodiment has prepared a kind of transition primer composition, comprises following weight percentage composition:

[0031]

[0032]Among them, the above-mentioned vinyl resin is selected as A-251 of Lihua Synthetic Resin; the above-mentioned defoamer is selected as BYK-141 of BYK Additives; the above-mentioned leveling agent is selected as BYK-331 of BYK Additives.

[0033] The preparation method and usage method are basically the same as those in Example 1, and will not be repeated here in order to save space.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com