Sapo-34 molecular sieve and its preparation method and application

A SAPO-34, molecular sieve technology, applied in the field of molecular sieve, can solve the problem of high preparation cost, achieve the effects of high selectivity, reduced raw material cost, easy washing and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The present invention provides a kind of preparation method of SAPO-34 molecular sieve on the one hand, this method comprises: aluminum source, phosphorus source, silicon source, templating agent I, templating agent II and water are contacted to carry out crystallization reaction, and crystallization reaction obtains The solid product is dried and calcined, wherein, the template agent I is morpholine and / or triethylamine, and the template agent II is tetramethylammonium bicarbonate and / or tetraethylammonium nitrate.

[0012] In the present invention, the aluminum source, phosphorus source, and silicon source can be materials commonly used in the art to prepare SAPO-34 molecular sieves. Preferably, the aluminum source is pseudoboehmite, aluminum sol, alumina , at least one of soluble aluminum salt and aluminum isopropoxide, the phosphorus source is at least one of phosphoric acid, diphosphoric acid, metaphosphoric acid, diammonium hydrogen phosphate (more preferably phosp...

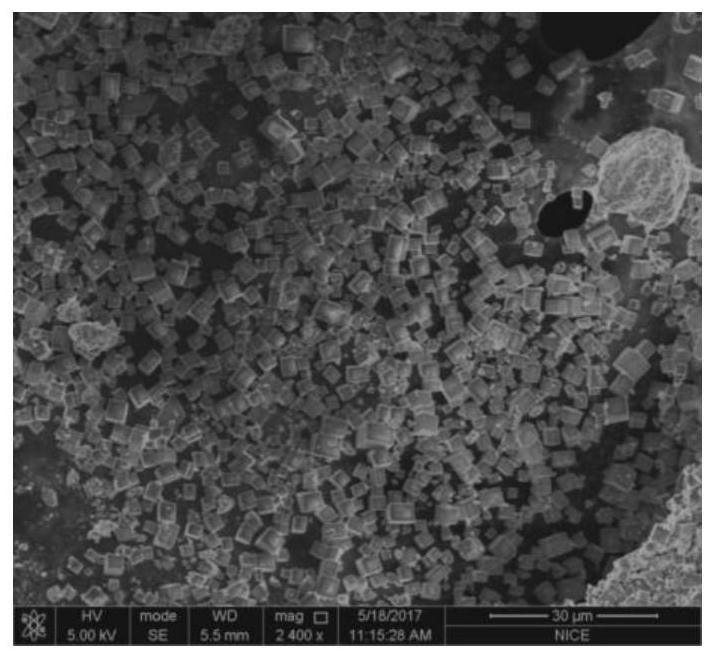

Embodiment 1

[0028] Mix pseudo-boehmite, phosphoric acid, aminopropyltrimethoxysilane, morpholine, tetramethylammonium bicarbonate and deionized water evenly, wherein the pseudo-boehmite is Al 2 o 3 In terms of phosphoric acid in P 2 o 5 In terms of aminopropyltrimethoxysilane as SiO 2 Calculated, the molar ratio of pseudo-boehmite, phosphoric acid, aminopropyltrimethoxysilane, morpholine, tetramethylammonium bicarbonate and deionized water is 1:0.9:0.75:0.05:1.8:60, and the crystallization After stirring evenly, crystallize at 210°C for 60 hours, take out the product, centrifuge to separate the solid product, wash the solid product with water, and dry it at 90°C for 8 hours to obtain the original SAPO-34 molecular sieve powder with a cubic structure. -34 molecular sieve raw powder was calcined at 600° C. for 5 hours to obtain SAPO-34 molecular sieve A1 with a particle size of 1-3 μm and cubic structure. The total diene selectivity of the SAPO-34 molecular sieve at 100% methanol conver...

Embodiment 2

[0031] Mix aluminum sol, phosphoric acid, ethyl orthosilicate, morpholine, tetraethylammonium nitrate and deionized water evenly, wherein the aluminum sol is Al 2 o 3 In terms of phosphoric acid in P 2 o 5 In terms of tetraethyl orthosilicate as SiO 2 Calculated, the molar ratio of aluminum sol, phosphoric acid, ethyl orthosilicate, morpholine, tetraethylammonium nitrate and deionized water is 1:1.4:0.15:5:0.2:18, prepare the crystallization solution, stir evenly, Crystallize at 160°C for 8 hours, take out the product, centrifuge to separate the solid product, wash the solid product with water and dry it at 150°C for 4 hours to obtain the cube-structured SAPO-34 molecular sieve raw powder, the SAPO-34 molecular sieve raw powder in Calcined at 480° C. for 10 h to obtain SAPO-34 molecular sieve A2 with a cubic structure with a particle size of 2-4 μm. The total diene selectivity of the SAPO-34 molecular sieve was 87.77% at 100% methanol conversion in methanol conversion to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com