Narrow tape gluing device and full-automatic mirror cabinet edge gluing machine based on same

A gluing device and gluing mechanism technology, applied in the direction of transportation and packaging, winding strips, sending objects, etc., can solve the problems of reducing the efficiency of gluing, wrinkles of the adhesive layer, and low winding tension, so as to improve the gluing The effect of glue quality, reducing wrinkles, and small tension deviation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples of implementation and accompanying drawings. The present invention can be implemented in the following ways:

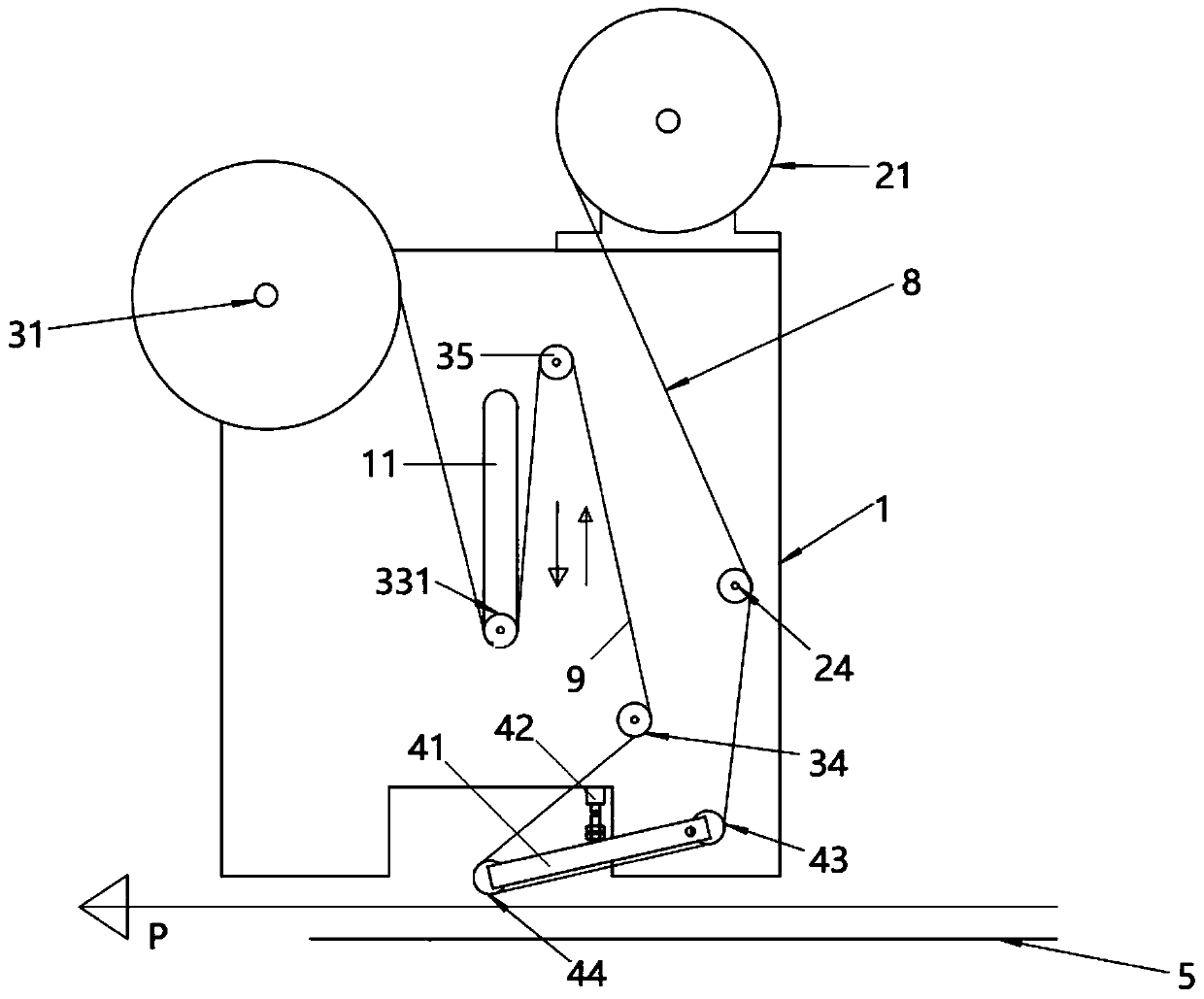

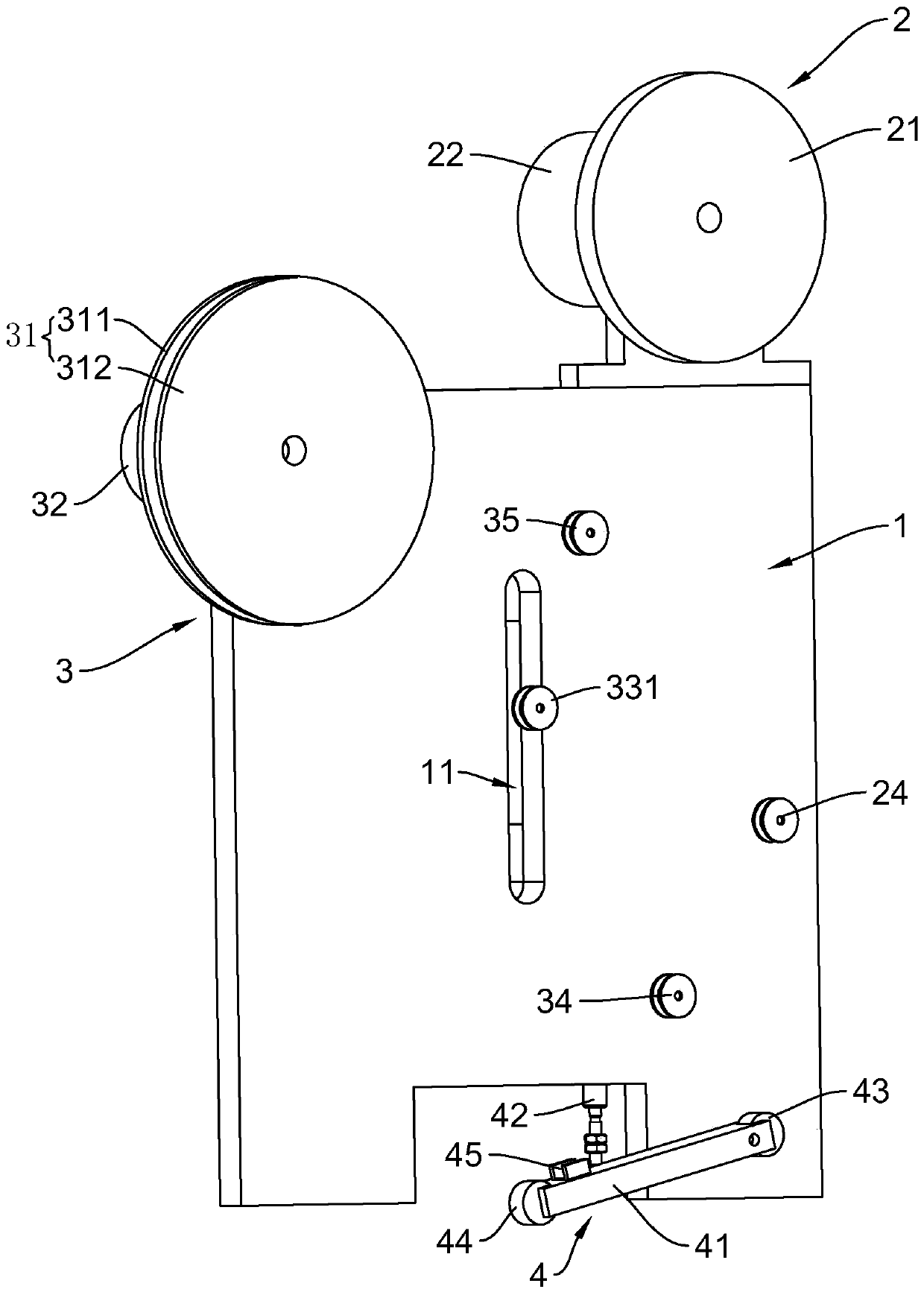

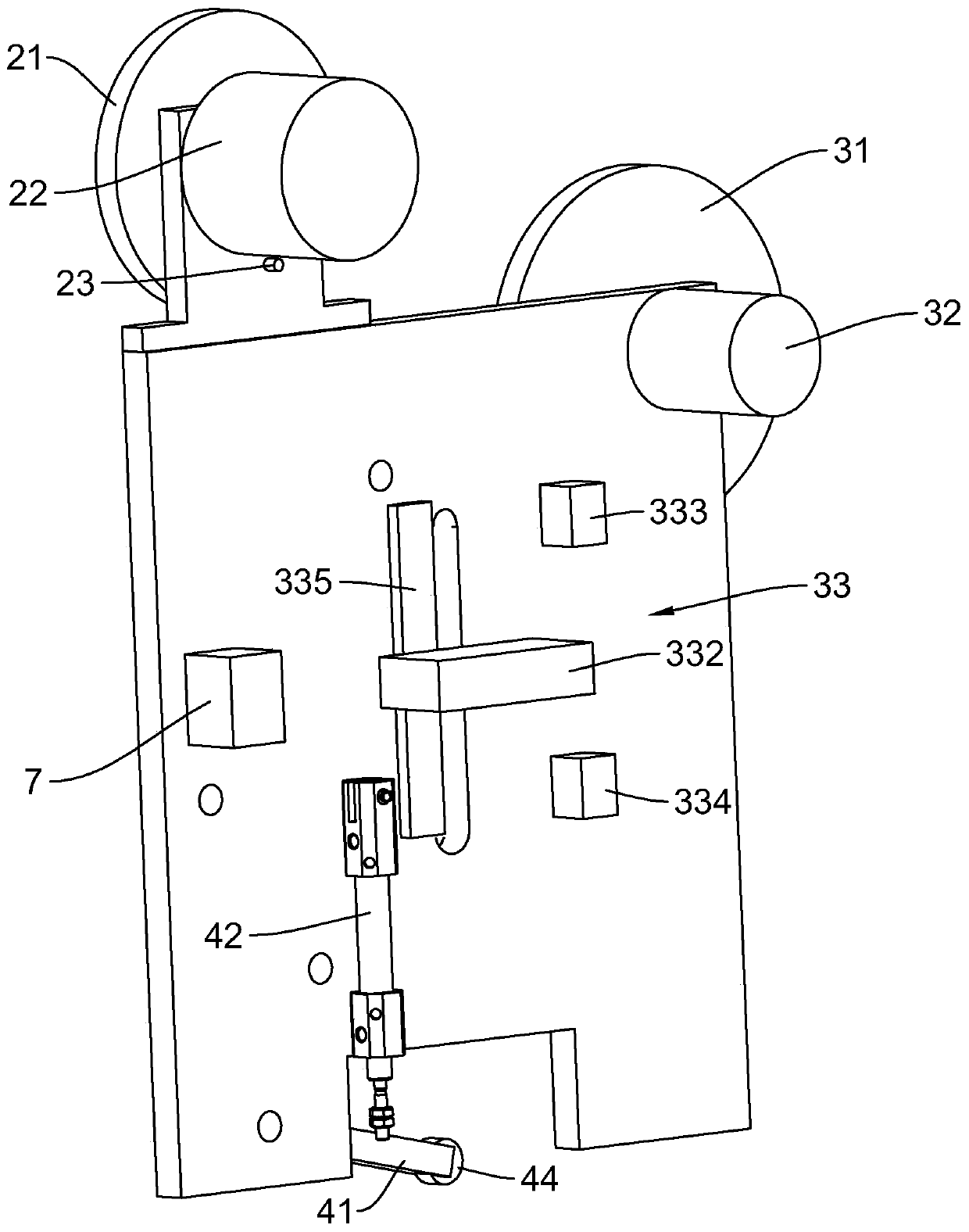

[0034] refer to Figure 1-3 , a narrow adhesive tape gluing device, including a mounting plate 1 arranged on the assembly line, the mounting plate 1 is provided with a discharge control mechanism 2, a material receiving control mechanism 3 and a gluing mechanism 4, and the gluing mechanism 4 It is located below the discharging control mechanism 2 and the receiving control mechanism 3; the adhesive tape is first unwound through the discharging control mechanism 2, and then the adhesive layer of the adhesive tape is separated from the release paper by the adhesive mechanism 4, and the adhesive layer is pasted on the On the edge of the mirror surface, the final release paper is rewound by the rewinding control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com