Horizontal type glass detection platform

A glass detection and glass technology, which is applied in the field of horizontal glass detection table, can solve the problems of low efficiency and achieve the effect of multiple functions, improved efficiency and fast detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

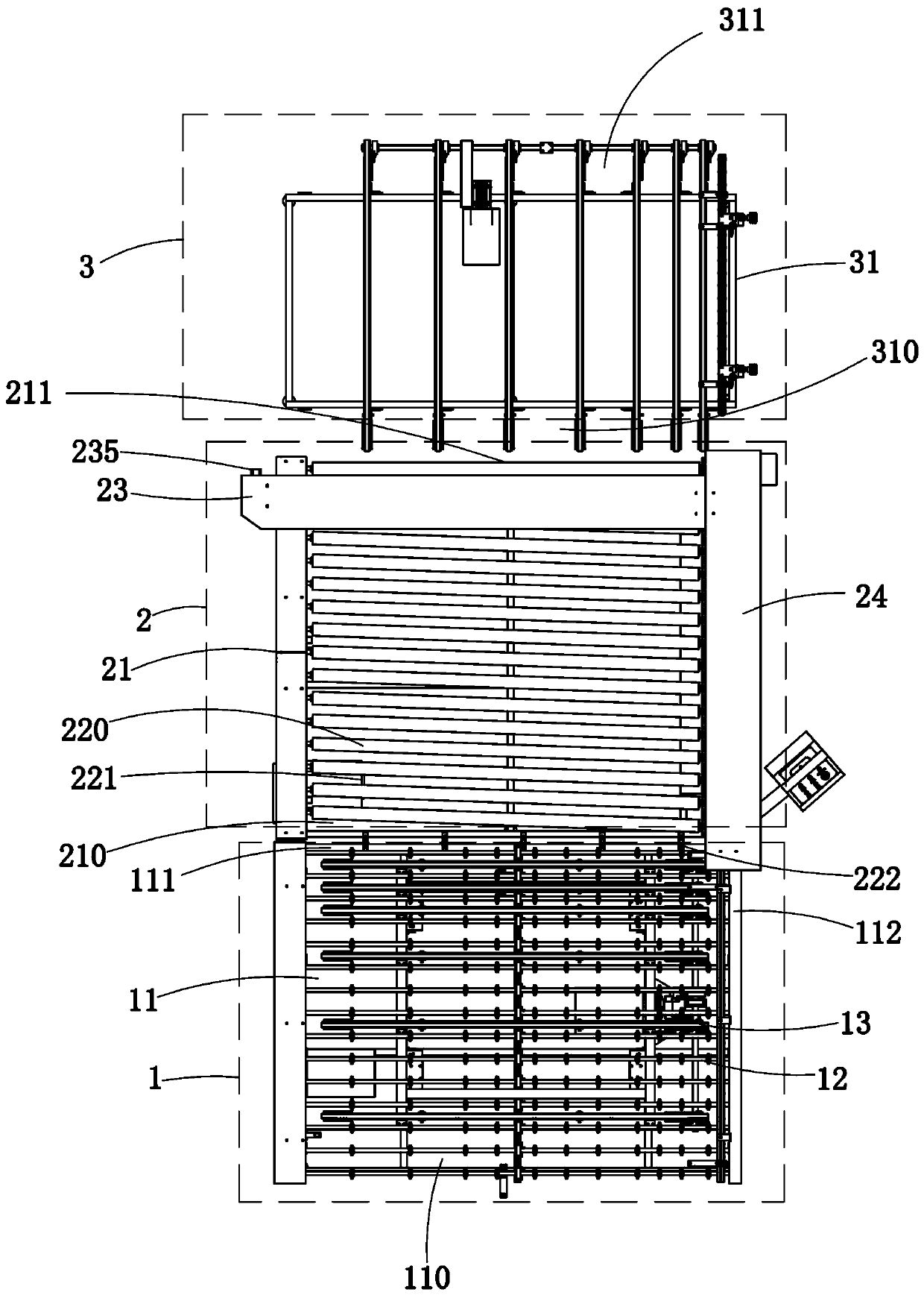

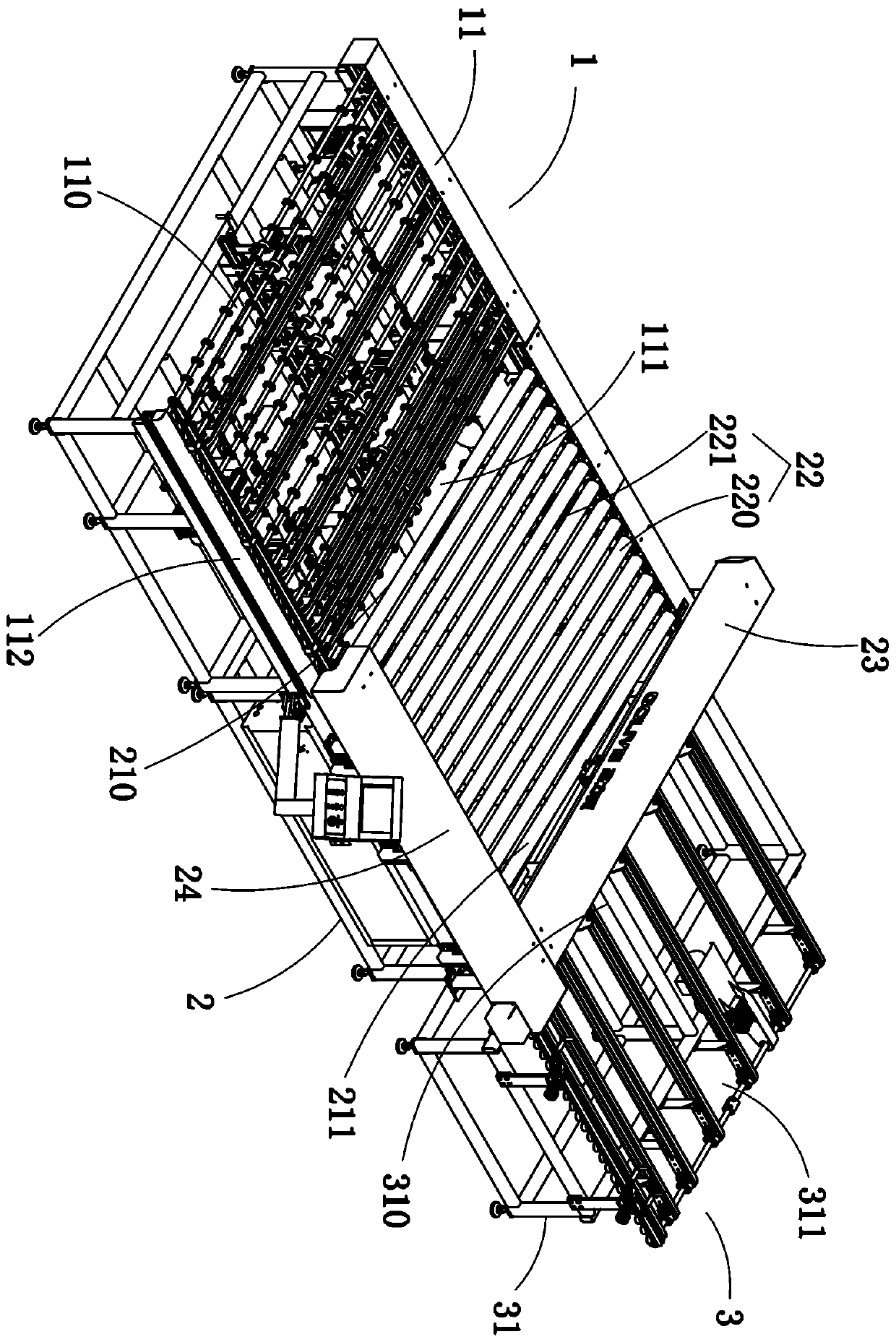

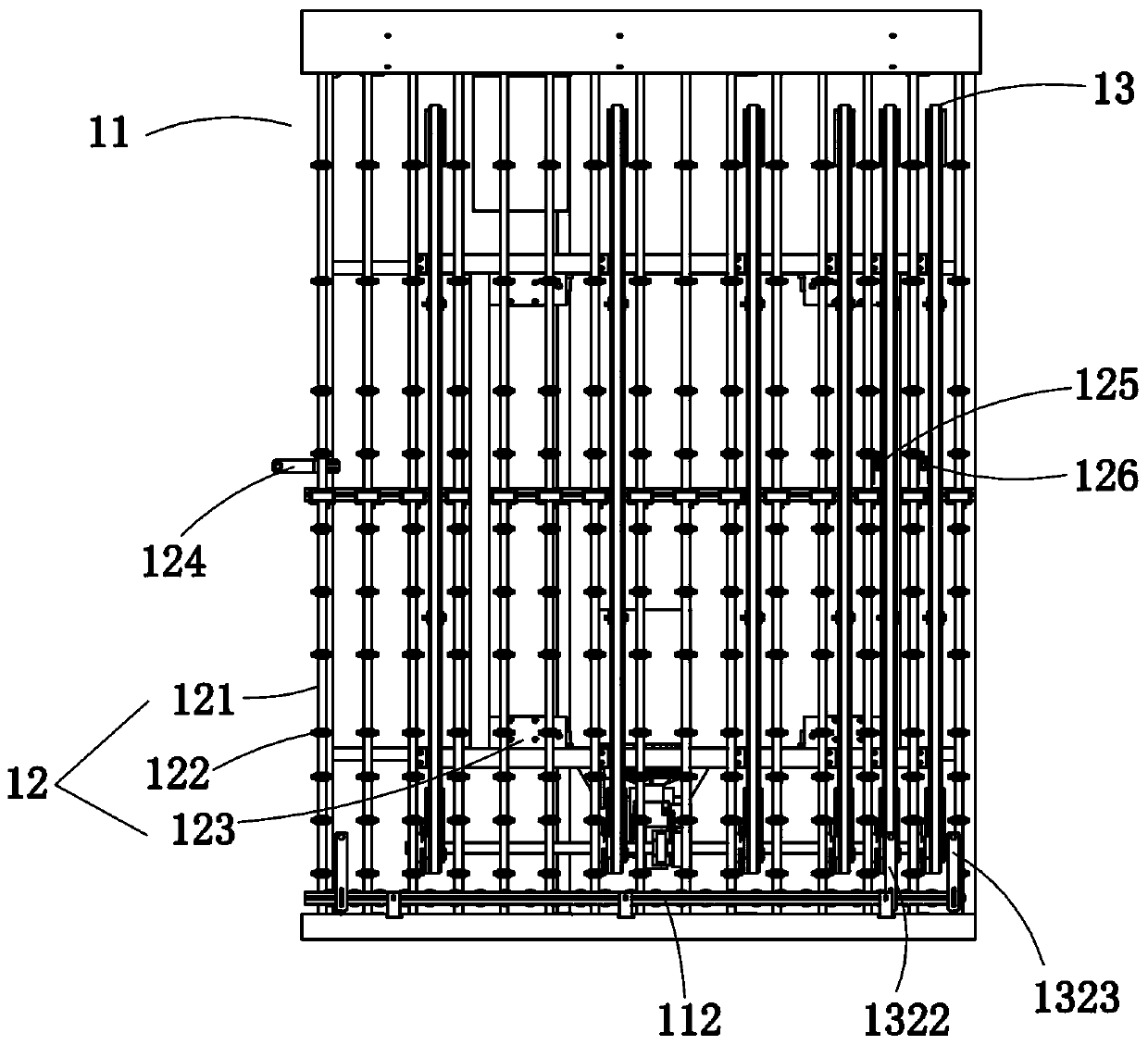

[0040] Examples, combined Figure 1 to Figure 10 As shown, a horizontal glass measuring table includes an edge section 1, a detection section 2, and a transition section 3. The detection section 2 is located between the edge section 1 and the transition section 3. The edge section 1 includes an edge table 11, The first glass transport device 12 used to drive the glass to move on the side table 11 and the side side device 13 used to close the glass to the side of the side table 11, the detection section 2 includes a measuring table 21, used to drive the glass on the measuring table 21 The moving second glass transport device 22, the X-axis measuring device 23 for measuring the transverse length of the glass, the Y-axis measuring device 24 for measuring the longitudinal length of the glass, and the thickness measuring device 25 for measuring the thickness of the glass, the transition section 3 includes a transition table 31 and a third glass transport device 32 for driving glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com