Forming device for marble manufacturing

A molding device, marble technology, applied in the direction of non-rotational vibration suppression, etc., can solve problems such as skin injury, marble skin injury, operator injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

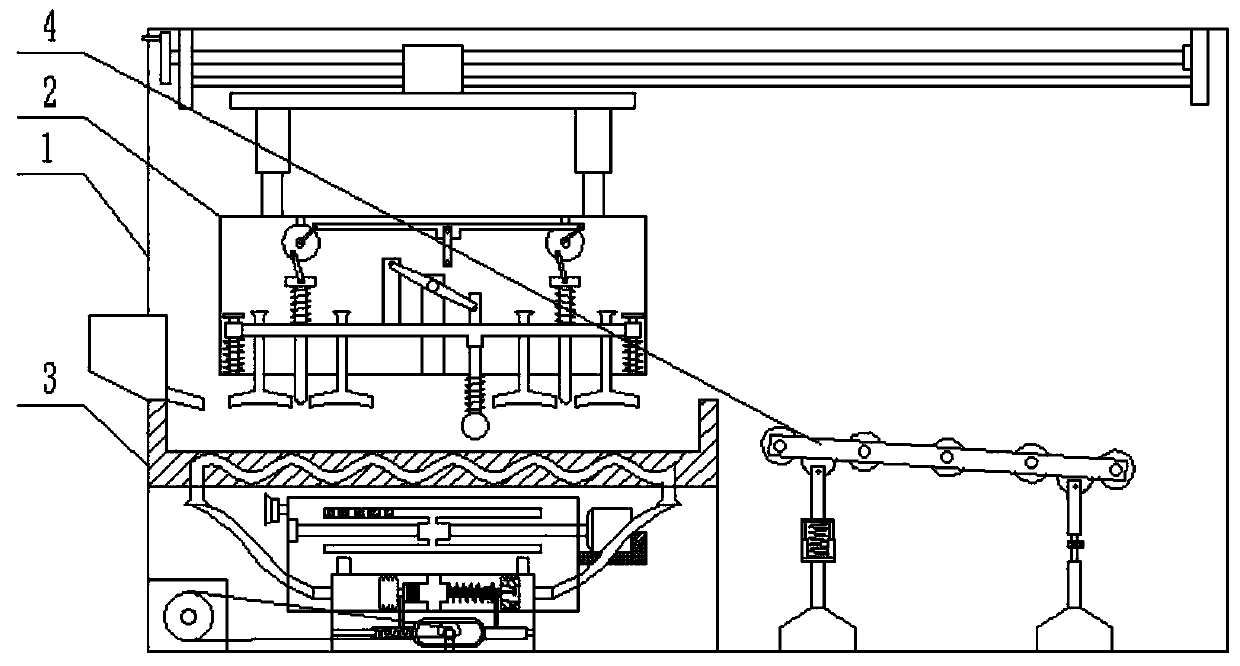

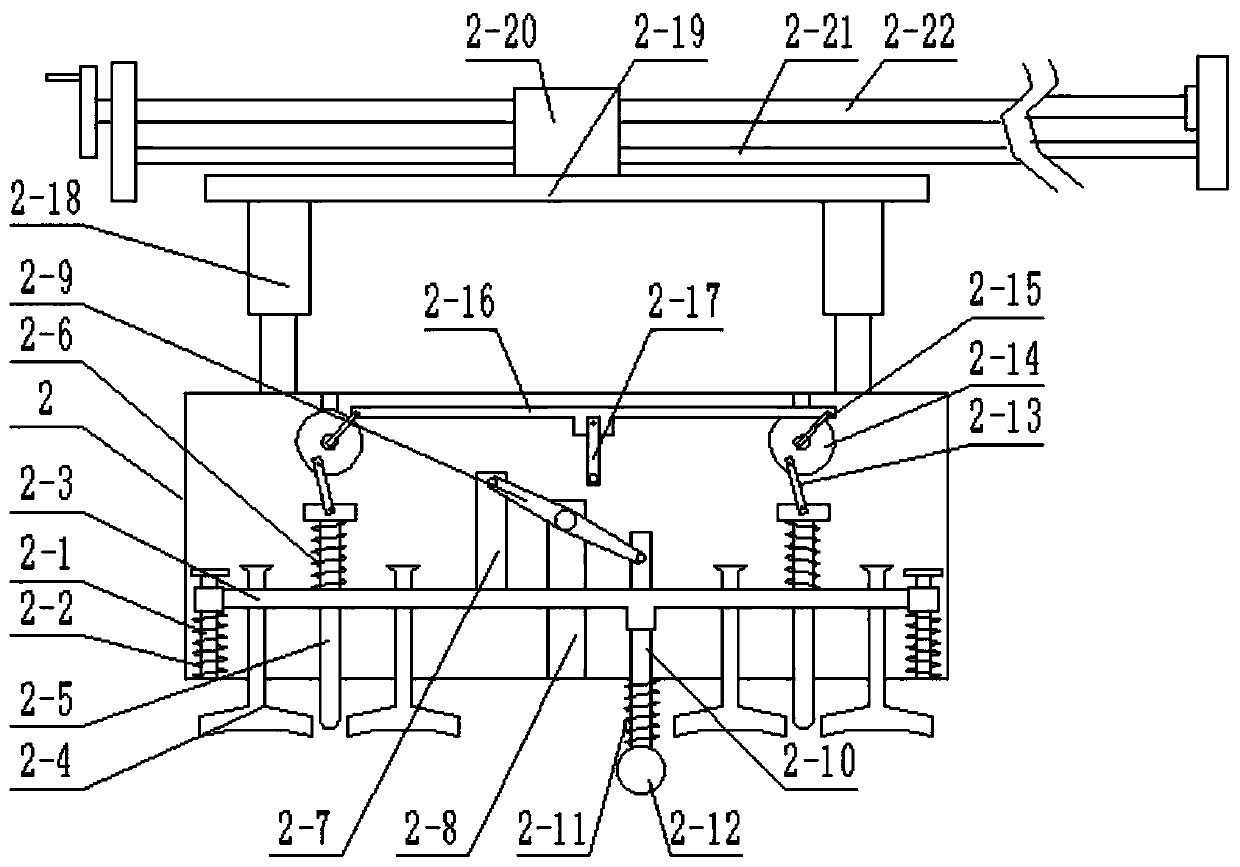

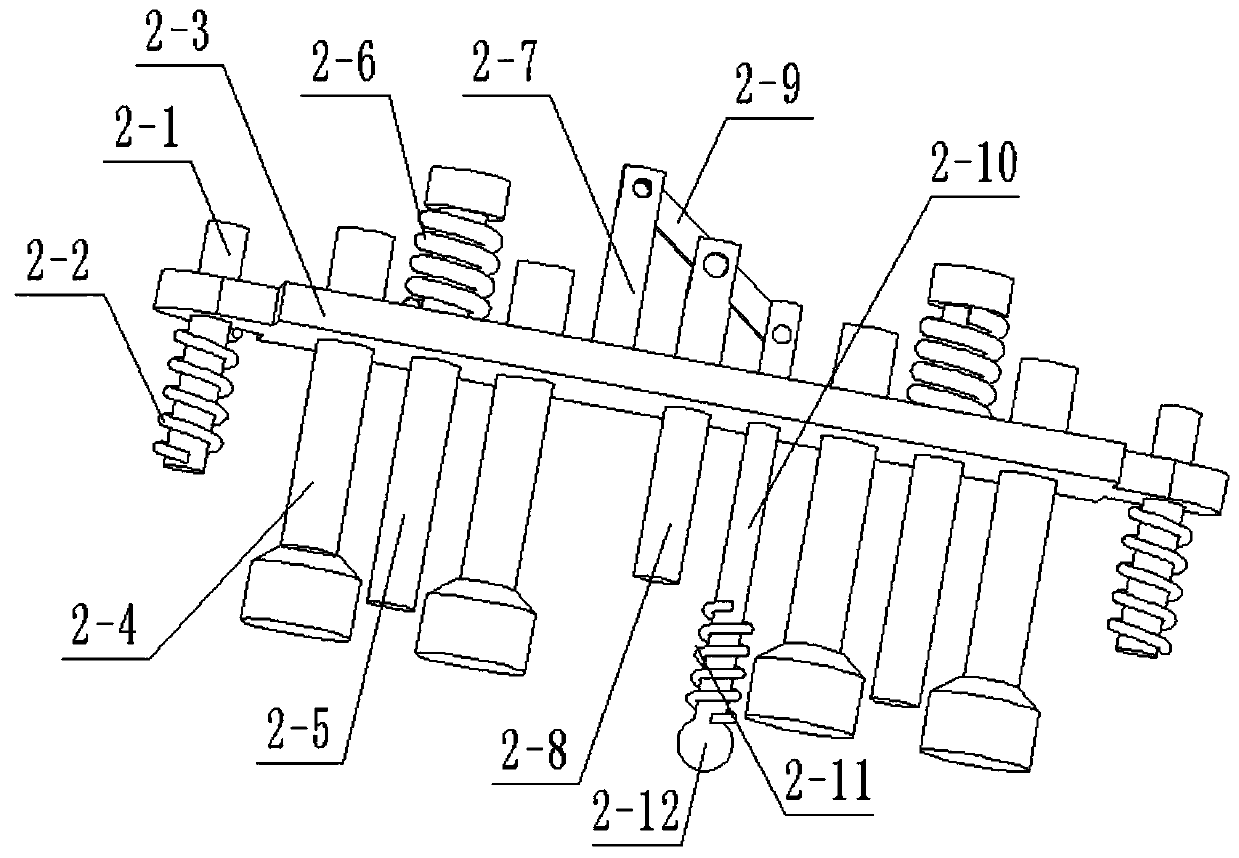

[0036] Combine below figure 1 , 2 . More specifically, it is a marble manufacturing molding device. Including shell 1, moving box 2, molding box 3, and transportation base 4, it can solve the preparation of marble by grinding raw material powder into powder and adding a mixture to make it. Marble needs to be heated and then mixed with a curing agent and then cooled. The problem to be dealt with in the next step can also solve the problem that the marble will generate high temperature during the heating and cooling process and easily injure the operator, and it can also solve the problem that the residual temperature of the marble just after cooling will cause damage to the skin.

[0037] The inside of the shell 1 is fixed with a mobile box 2 , the inside of the shell 1 is fixed with a forming box 3 , and the inside of the shell 1 is fixed with a transport base 4 .

specific Embodiment approach 4

[0041] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, and 17 illustrate this implementation mode. The upper end of seat 4 is provided with transport roller 4-1, damping base 4-2, damping sleeve 4-3, damping sliding plate 4-4, damping spring 4-5, damping base support arm 4 -6, angle adjustment base 4-7, angle adjustment sleeve 4-8, two-way threaded screw 4-9, the upper end of transport base 4 rotates with transport roller 4-1, the upper end of damping base 4-2 The damping sleeve 4-3 is fixed, and the inside of the damping sleeve 4-3 slides with a damping sliding plate 4-4, and the upper end of the damping sleeve 4-3 is fixed with a damping spring 4-5, and the damping slides The upper end of plate 4-4 is welded with damping base support arm 4-6, and the upper end of damping slide plate 4-4 is hinged with damping base support arm 4-6, and the upper end of angle adjustment base 4-7 is fixed with The angle adjustment sleeve 4-8 is provided with a t...

specific Embodiment approach 5

[0043] Combine below figure 1 , 2 . 16. The one-way valve D3-18 is connected to the cooling pipe 3-2 through a hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com