Ultra-thin and ultra-wide stainless steel strip rolling process

A stainless steel strip, ultra-thin technology, applied in the direction of metal rolling, contour control, etc., can solve the problems of low yield of narrow ultra-thin stainless steel, unable to meet the use requirements, low market application value, etc., to achieve high quality, solve the problem of Type difference and stable surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

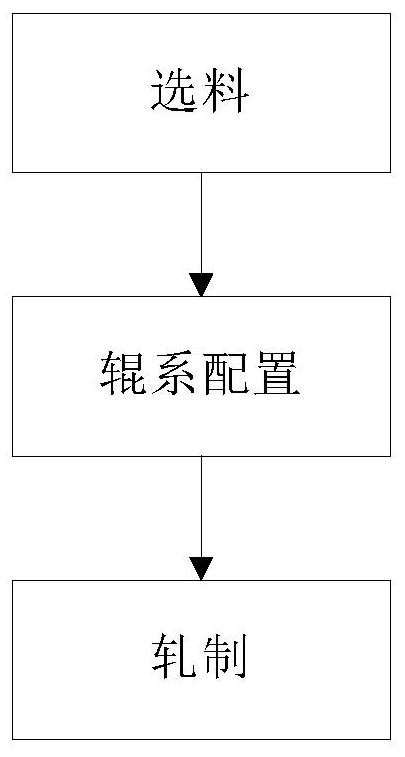

Method used

Image

Examples

Embodiment 1

[0046] A cold-rolled stainless steel coil with a thickness of 0.1mm and a width of 650mm is selected as the raw material, and the target thickness of the finished steel strip is 0.025mm.

[0047] The stainless steel cold-rolled coil with a thickness of 0.1mm is rolled by a 20-roller mill. During rolling, BP rolling oil is used for lubrication and cooling. The temperature of the rolling oil is 40°C. It is rolled to 0.025mm by 7 passes. The rolling speed of each pass is 160m / min, the deformation of each pass is 24%, the rolling speed of other passes is 350m / min, the deformation of each pass is within 18.6%, the rolling speed of the finished product is 150m / min, The secondary deformation is 8.5%.

[0048] Tension control adopts direct tension control, and the first pass entrance tension is set to 100N / mm according to the amount of deformation 2 , the outlet tension is controlled at 215N / mm 2 , the entrance tension of the remaining passes increases by about 30N / mm 2 , the outle...

Embodiment 2

[0055] A cold-rolled stainless steel coil with a thickness of 0.08mm and a width of 650mm is selected as the raw material, and the target thickness of the finished steel strip is 0.03mm.

[0056] The raw material of stainless steel cold-rolled coil with a thickness of 0.08mm is rolled by a 20-roller mill. During rolling, rolling oil is used for lubrication and cooling. The temperature of the rolling oil is 40°C. The rolling speed of each pass is 160m / min, and the deformation of each pass is 25%. The rolling speed of other passes is 260m / min, and the deformation of each pass is within 18.3%. The secondary deformation is 8.3%;

[0057] Tension control adopts direct tension control, and the first pass entrance tension is set to 100N / mm according to the amount of deformation 2 , the outlet tension is controlled at 215N / mm 2 , the entrance tension of the remaining passes increases by about 26N / mm 2 , the outlet tension increases by about 30N / mm 2 , the entrance tension of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com