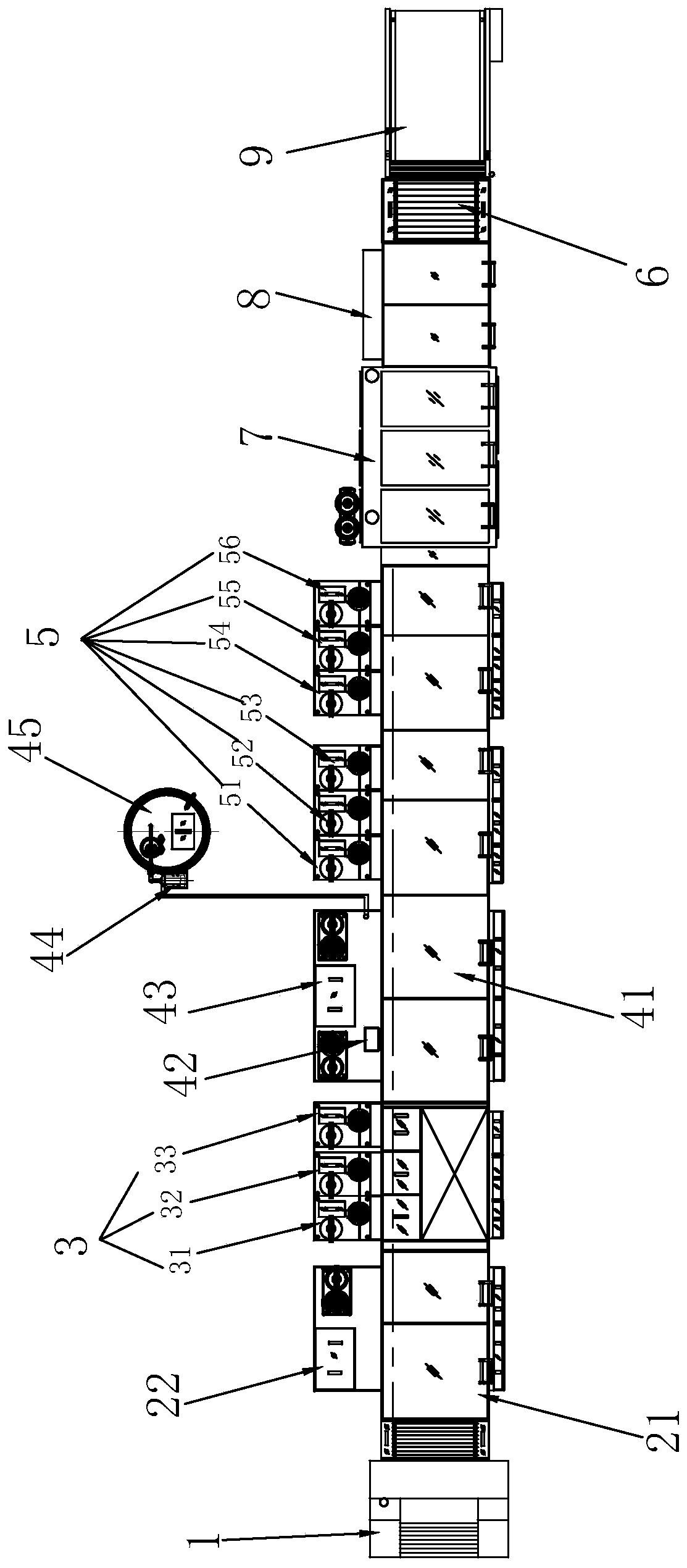

Cleaning process and device for removing ionic contamination from PCB (printed circuit board)

A PCB board and deionization technology, applied in the field of PCB ion cleaning, can solve the problems of ion cleaning process failing to reach customers, ignoring oxide layers, etc., and achieve the effect of reducing ion pollution, saving labor costs, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preferably, the liquid medicine used for pickling is a citric acid solution, wherein the mass percent concentration of citric acid is controlled at 4%.

[0038] Preferably, the pickling includes using pickling solution to rinse the PCB board by spraying, and the spraying pressure is controlled at 1.5Kg / cm 2 , The temperature value of the pickling solution is controlled at 20°C.

[0039]Preferably, in order to wash away the remaining chemical solution for pickling in the pickling, the first multi-stage overflow washing sequentially includes overflow washing one, overflow washing two, and overflow washing three; wherein the overflow washing The first and the overflow washing are distilled water, which is used to initially wash off the pickling solution and other impurities on the PCB, and then the overflow washing is the third washing with DI. DI water is deionized water, which removes impurities in the form of ions. Water, DI water meets the requirements of ion pollutio...

Embodiment 2

[0044] Preferably, the liquid medicine used for pickling is a citric acid solution, wherein the mass percent concentration of citric acid is controlled at 5%.

[0045] Preferably, the pickling includes using pickling solution to rinse the PCB board by spraying, and the spraying pressure is controlled at 1.5Kg / cm 2 , The temperature value of the pickling solution is controlled at 30°C.

[0046] Preferably, in order to wash away the remaining chemical solution for pickling in the pickling, the first multi-stage overflow washing sequentially includes overflow washing one, overflow washing two, and overflow washing three; wherein the overflow washing The first and the overflow washing are distilled water, which is used to initially wash off the pickling solution and other impurities on the PCB, and then the overflow washing is the third washing with DI. DI water is deionized water, which removes impurities in the form of ions. Water, DI water meets the requirements of ion polluti...

Embodiment 3

[0051] Preferably, the liquid medicine used for pickling is a citric acid solution, wherein the mass percent concentration of citric acid is controlled at 6%.

[0052] Preferably, the pickling includes using pickling solution to rinse the PCB board by spraying, and the spraying pressure is controlled at 2Kg / cm 2 , The temperature value of the pickling solution is controlled at 40°C.

[0053] Preferably, in order to wash away the remaining chemical solution for pickling in the pickling, the first multi-stage overflow washing sequentially includes overflow washing one, overflow washing two, and overflow washing three; wherein the overflow washing The first and the overflow washing are distilled water, which is used to initially wash off the pickling solution and other impurities on the PCB, and then the overflow washing is the third washing with DI. DI water is deionized water, which removes impurities in the form of ions. Water, DI water meets the requirements of ion pollution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com