Potato and peanut harvesting machine

A technology for peanut harvesters and potatoes, which is applied to digging harvesters, harvesters, excavators, etc., can solve the problems of high labor intensity, different crop varieties, and poor versatility, so as to save harvesting costs and improve market prospects The effect of opening up and saving manpower work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

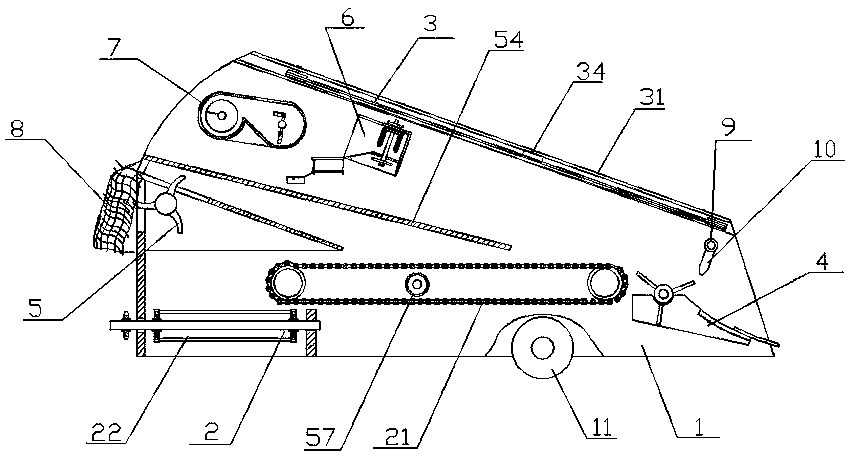

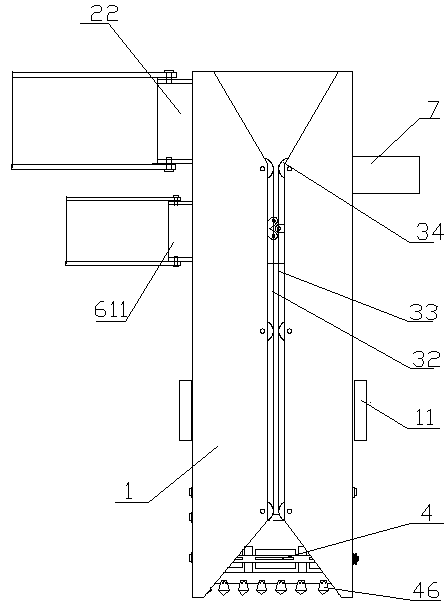

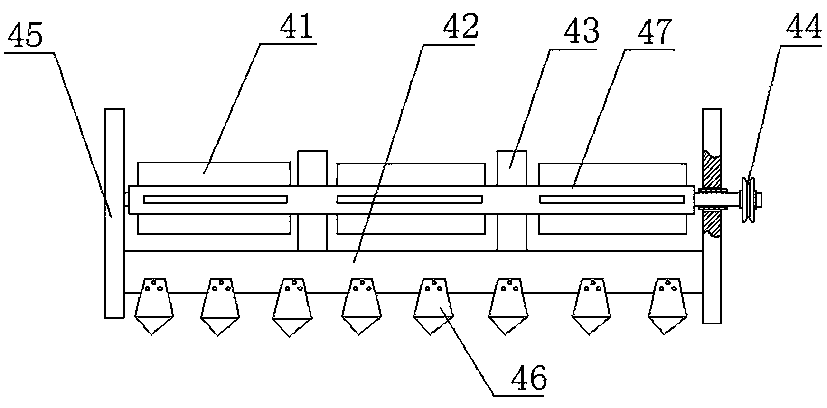

[0036] refer to Figure 1-16 , a potato and peanut harvester, comprising a frame 1, the rear end of the frame 1 is provided with a hitch frame hinged with the tractor, and a lift cylinder can also be connected to the rear upper end of the frame, and the rear lower end of the frame is provided with A hanging ear is convenient for other power machinery connection. The lower end of the lower frame is provided with a walking wheel 11, and the frame 1 is provided with a potato conveyor 2, a peanut conveyor 3, a plow frame 4, a plastic film recovery device 5, a peanut picking device 6 and a peanut seedling killing device 7, and the plow frame 4 is arranged at the front end of the frame, the potato conveyor 2 is located at the rear side of the frame 1, the feeding port of the potato conveyor 2 corresponds to the discharge end of the upper end of the plow frame 4, and the discharge end of the potato conveyor 2 extends To the outside of the frame 1, the film recovery device 5 is posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com