II-type collector fault disassembling, sorting and detecting device

A detection device and collector technology, applied in receiver monitoring, transmitter monitoring, etc., can solve problems such as low maintenance efficiency, reduce work intensity, avoid waste of resources, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

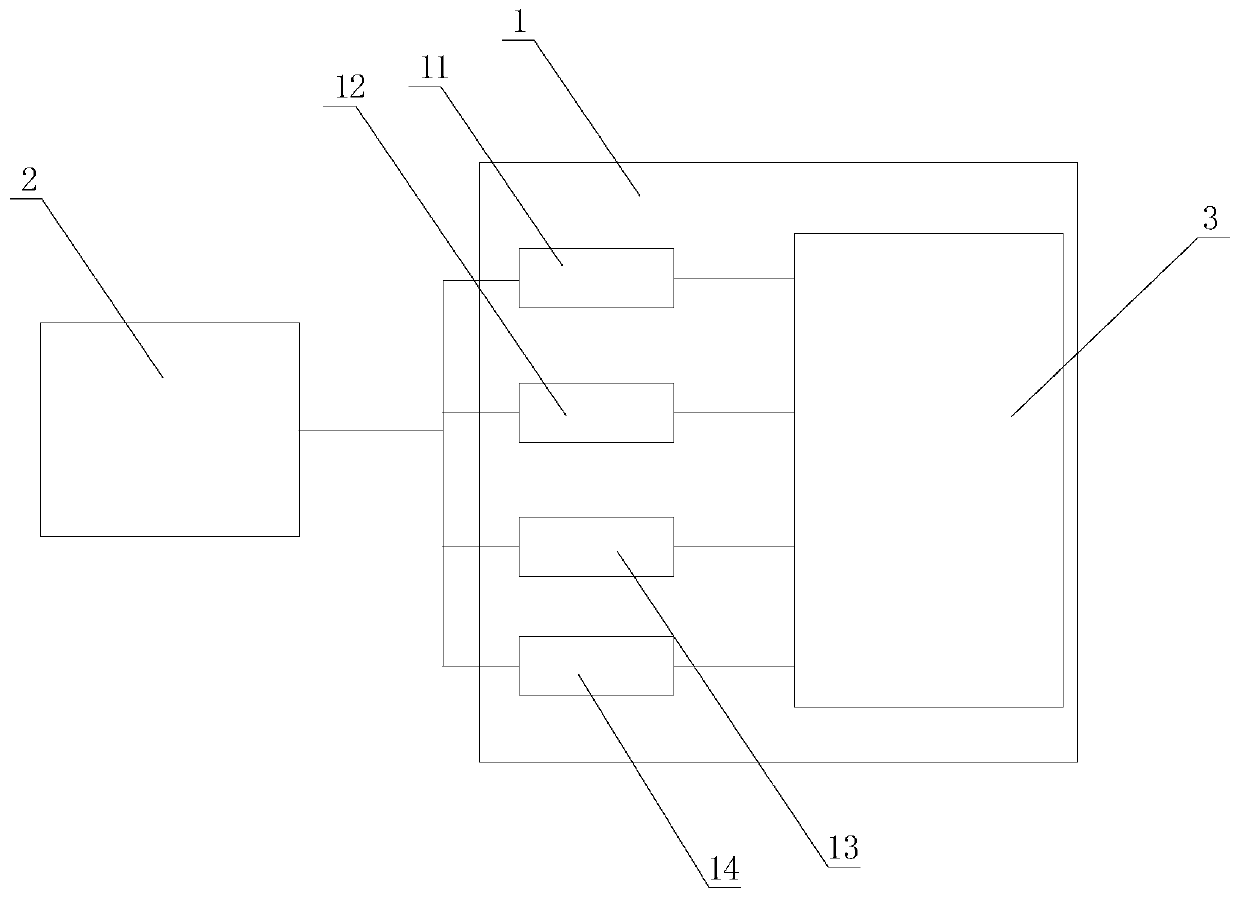

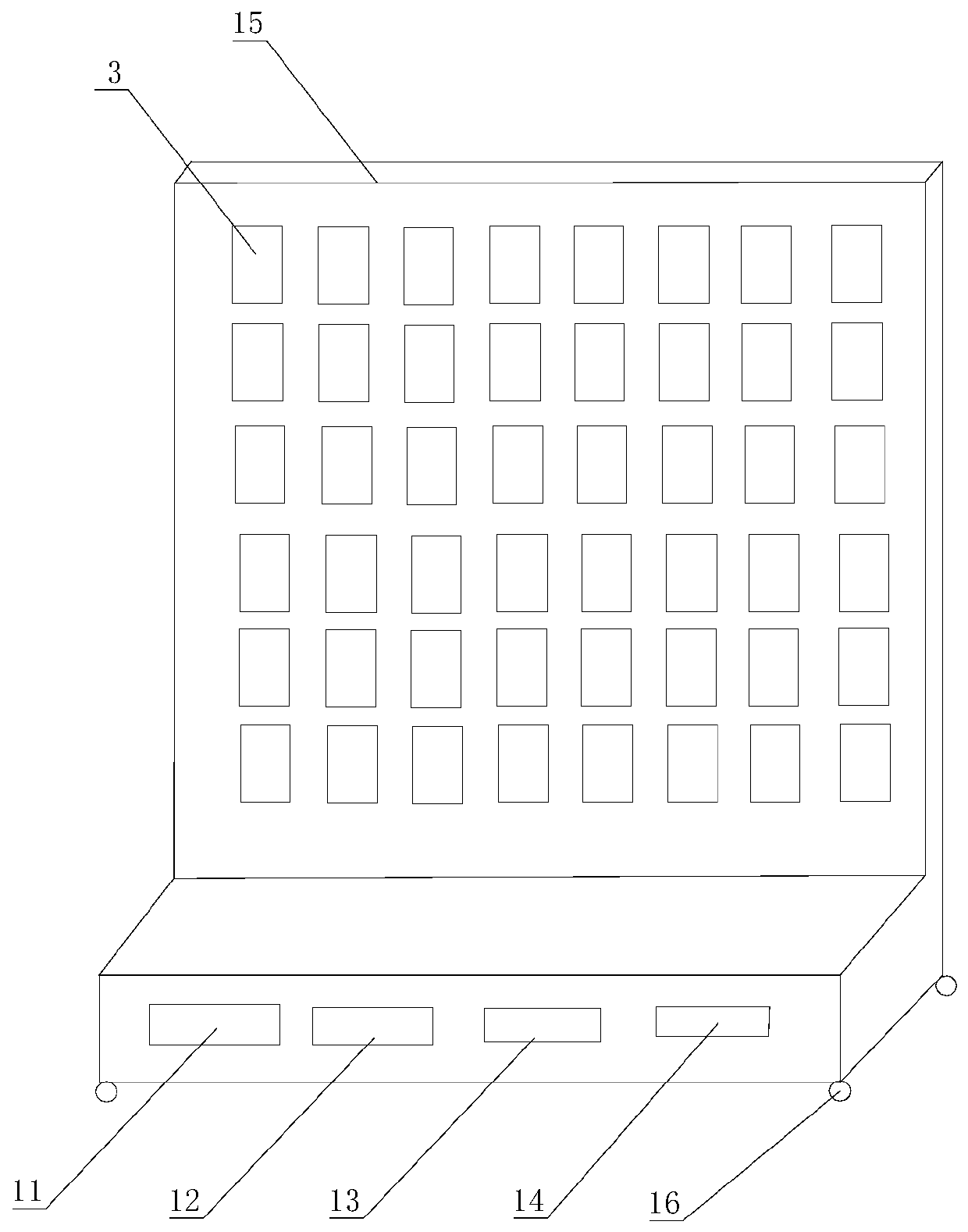

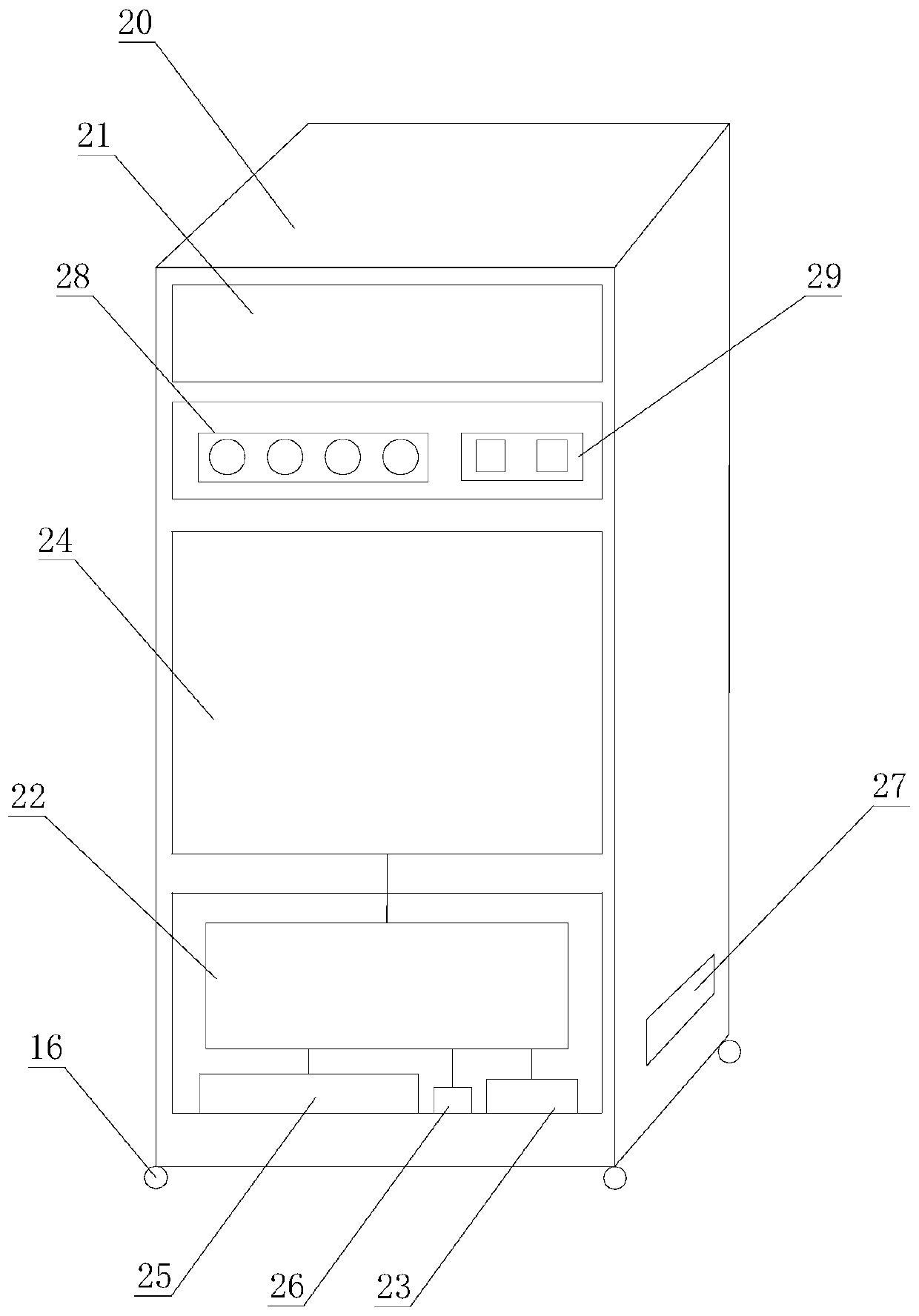

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a type II collector fault dismantling and sorting detection device includes a test bench 1 and a control cabinet 2 connected to the test bench 1, and the test bench 1 includes an output comparison source for providing an accurate test clock Clock test module 11, 485 communication test module 12 for simulating 485 communication test, infrared communication test module 13 for infrared communication test function, carrier communication and micropower configuration test for Type II collector The carrier test module 14 of communication test, and the independent test surface system 3, described test surface system 3 comprises the infrared probe 31 that links to each other with infrared communication test module 13, and the port that is connected with II type collector signal 32. The 485 communication test module 12 is connected to the port 32; the control cabinet 2 sends test parameters and passes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com