Photovoltaic frame of solar cell

A solar cell and photovoltaic technology, applied in the field of solar cells, can solve problems such as component heating, lower power generation efficiency on the back of the component, and increased risk of component failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

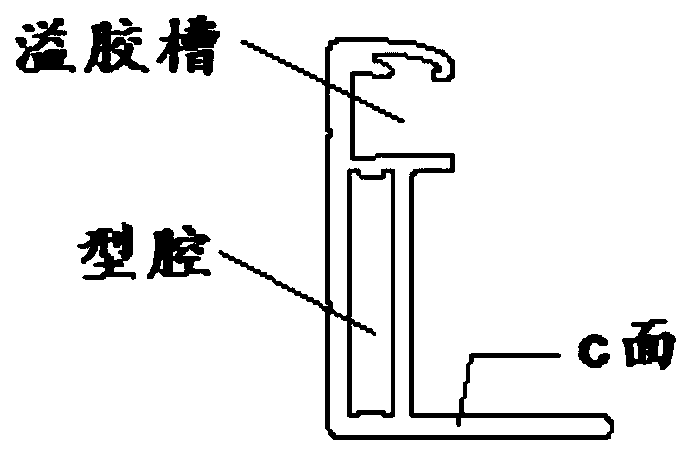

[0021] The core of the present invention is to provide a photovoltaic frame. see figure 1 , figure 1 It is a structural schematic diagram of a photovoltaic frame in the prior art. In the prior art, in order to ensure that the photovoltaic frame can support the solar cells, a c-plane is usually arranged in the photovoltaic frame. However, due to the existence of the c-plane, the back of the solar cell will be greatly blocked, so that the photovoltaic frame in the prior art is not suitable for double-sided solar cells. The c-plane not only reduces the efficiency of power generation on the back of the module, but also may cause hot spots, leading to local heating of the module and increasing the risk of module failure.

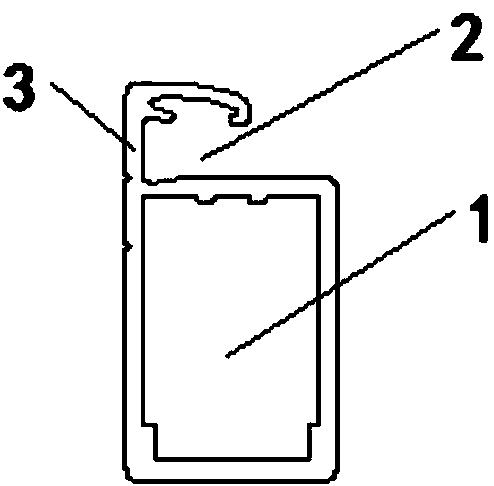

[0022] And the photovoltaic frame of a kind of solar cell that the present invention provides, comprises mold cavity and the glue overflow groove that is fixedly connected with mold cavity; The wall is in direct contact with any side wall of the cavity to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com