Preparation method of single crystal particle ternary positive electrode material

A technology of single crystal particles and positive electrode materials, applied in the direction of positive electrodes, electrical components, battery electrodes, etc., can solve the problems of uneven distribution and diffusion of materials on the surface, shortened service life of positive electrodes, uneven local lithium source, etc., and achieve high Effects of energy density, side reaction reduction, and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

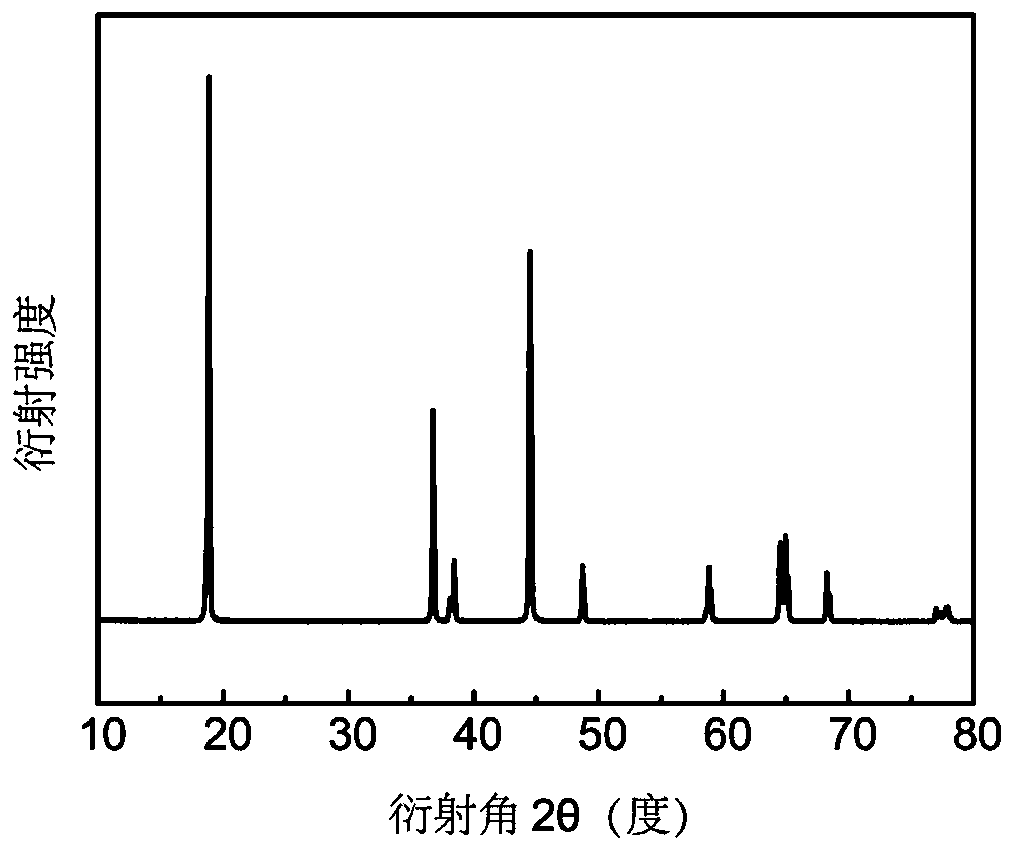

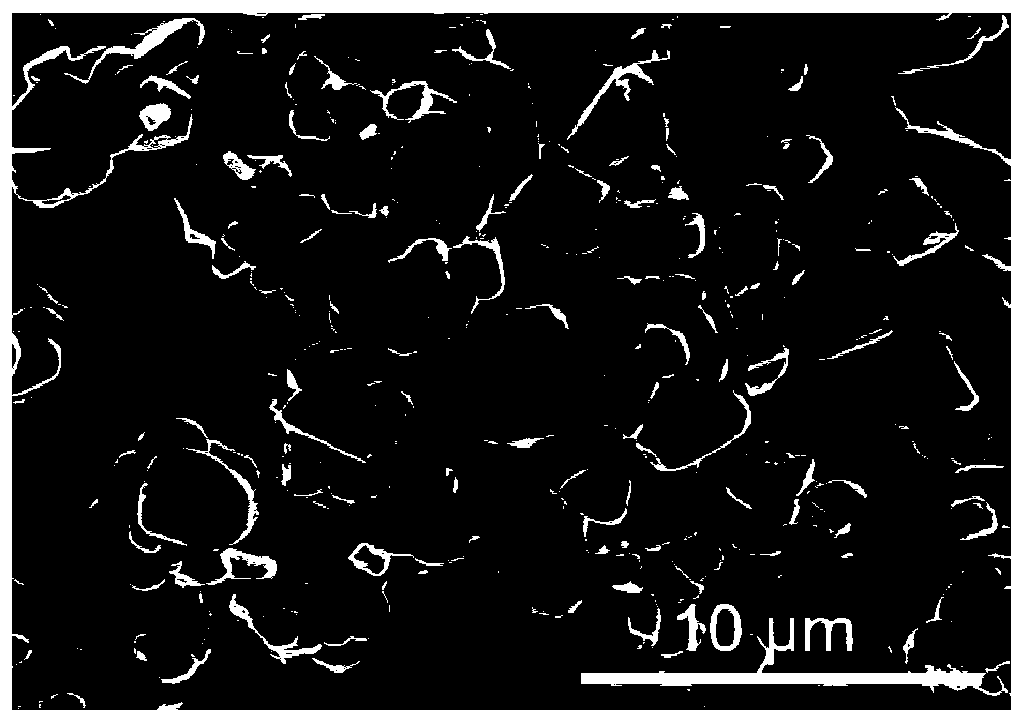

Embodiment 1

[0032] Firstly, 2μm Ni with D50 0.8 co 0.1 mn 0.1 (OH) 2 The precursor and lithium hydroxide are weighed according to the stoichiometric number, and potassium acetate is added as the first solid additive, wherein the molar ratio of the lithium source, the ternary precursor and the first solid additive is 1.1:1:0.4, and the mixture is uniform. The mixture was placed in an oxygen atmosphere furnace with an oxygen volume ratio of 95% at 5 °C min -1 The heating rate is increased to 450°C and kept for 10 hours; then at 5°C·min -1 The heating rate is raised to 800°C and kept for 15 hours; then cooled to 700°C and kept for 10 hours. There are three sinterings in total, and the sintering process ends. Then it was treated with water at a temperature of 50°C for a total of 20 hours, and then placed in an oxygen atmosphere furnace for heat treatment at 700°C for 15 hours. The NCM 811 ternary lithium battery positive electrode material with large primary particle size was obtained. ...

Embodiment 2

[0034] Firstly, 2μm Ni with D50 0.8 co 0.1 mn 0.1 (OH) 2 The precursor and lithium hydroxide are weighed according to the stoichiometric number, and then lithium oxalate is added as the first solid additive, wherein the molar ratio of the lithium source, the ternary precursor and the first solid additive is 1.05:1:0.2, and the mixture is uniform. The mixture was placed in an oxygen atmosphere furnace with an oxygen volume ratio of 95% at 5 °C min -1 The heating rate is increased to 450°C and kept for 10 hours; -1 The heating rate is raised to 800°C and kept for 10 hours; then lowered to 700°C and kept for 10 hours, a total of three sinterings, and the sintering process ends. After the sintering is completed, it is then washed with water at a temperature of 50°C for 12 hours, and then placed in an oxygen atmosphere furnace for heat treatment at 700°C for 15 hours to obtain NCM811 ternary lithium battery cathode material with a large primary particle size.

Embodiment 3

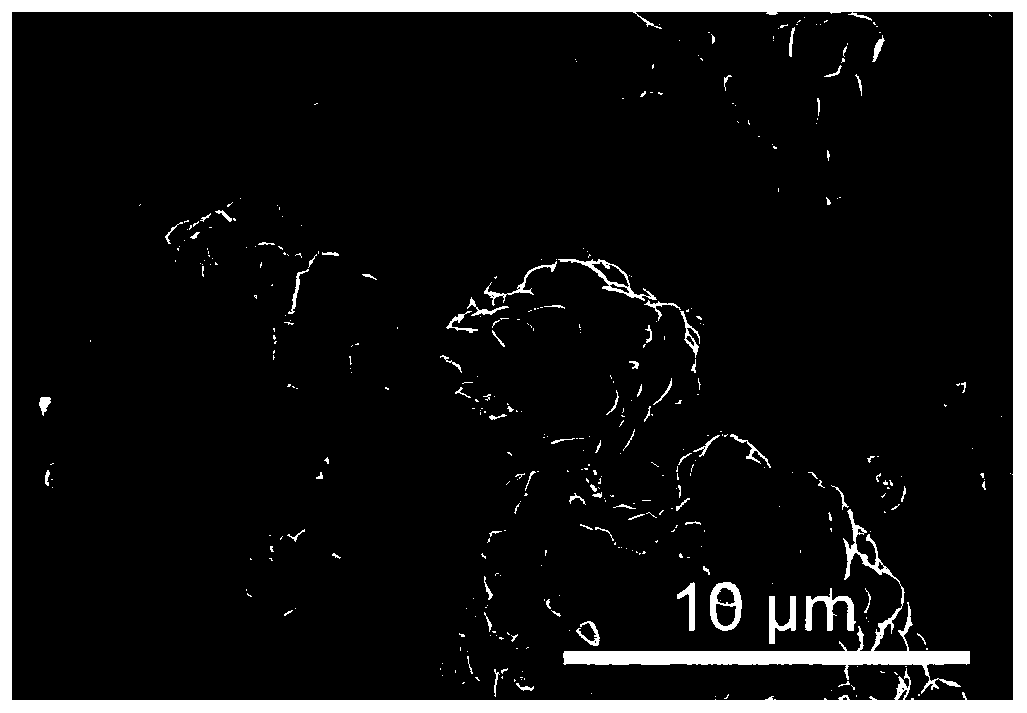

[0036] First set D50 to 2μm Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor and lithium hydroxide are weighed according to the stoichiometric number, and then sodium citrate is added as the first solid additive, wherein the molar ratio of the lithium source, the ternary precursor and the first solid additive is 1.08:1:0.3, and the mixture is uniform . The mixture was placed in an oxygen atmosphere furnace with an oxygen volume ratio of 95% at 5 °C min -1 The heating rate is increased to 500°C and kept for 10 hours; -1 The heating rate was raised to 700°C and kept for 8 hours; then at 10°C·min -1 The heating rate is raised to 900°C and kept for 8 hours; then cooled to 700°C and kept for 8 hours. There are four sinterings in total, and the sintering process is ended. After the sintering is completed, it is placed in an oxygen atmosphere furnace for heat treatment at 550°C for 10 hours to obtain NCM 811 ternary lithium battery cathode material with a large primary particle size. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com