Fatigue test method of wind power blade

A technology for wind power blade and fatigue testing, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problems of reducing the loading efficiency of the exciter and the resonance frequency of the test system, so as to improve the loading efficiency. , to avoid the effect of insufficient loading force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

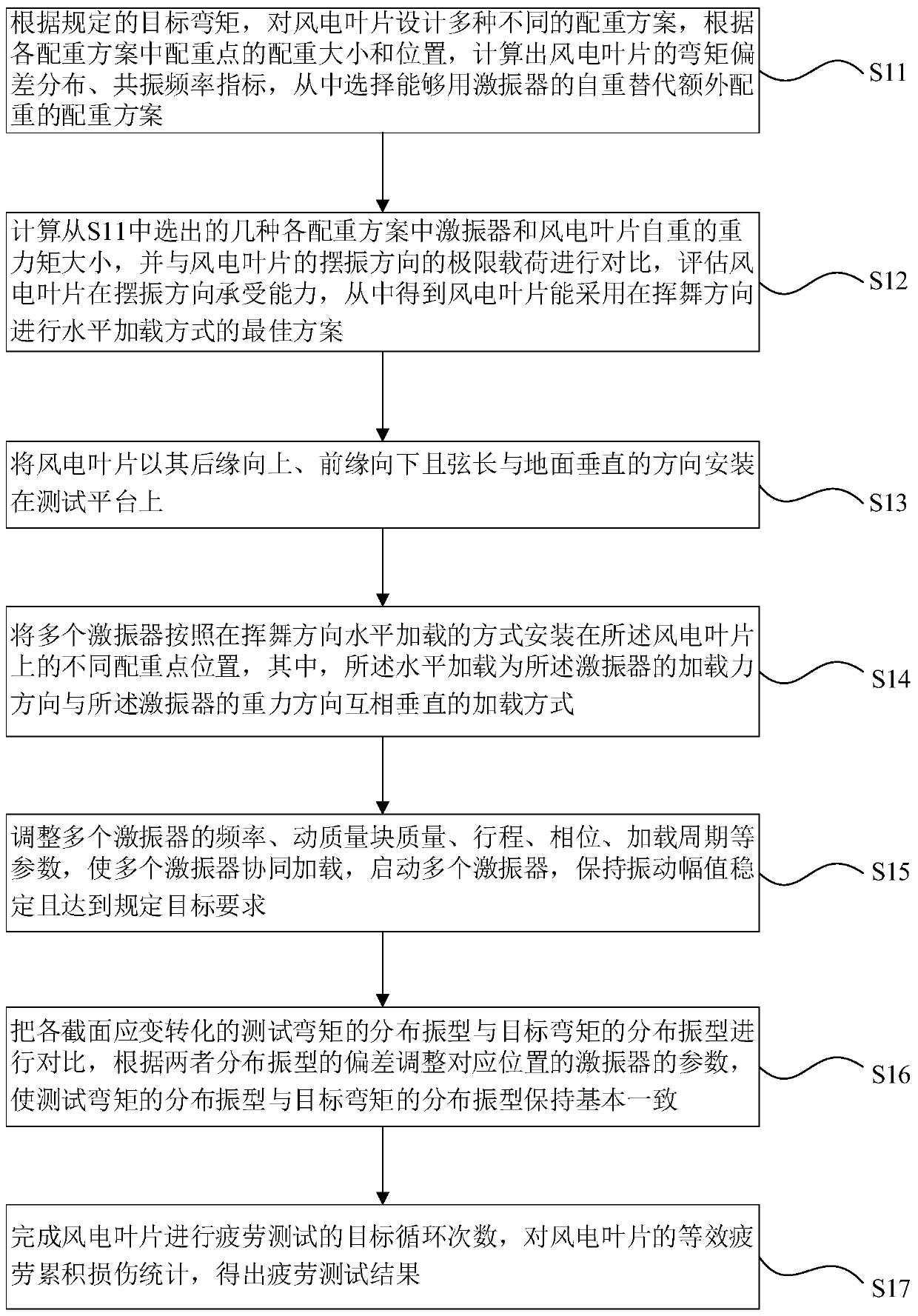

[0045] Such as figure 1 Shown, the fatigue testing method of a kind of wind power blade of the present invention comprises the following steps:

[0046] S11. According to the specified target bending moment, design a variety of different counterweight schemes for the wind turbine blades, and calculate the bending moment deviation distribution and resonance frequency of the wind turbine blades according to the size and position of the counterweights in each counterweight scheme Index, from which to choose the counterweight scheme that can replace the extra counterweight with the self-weight of the exciter. In this step, a variety of test schemes are designed before testing the wind turbine blades according to the requirements, and several counterweight schemes can be selected from which the self-weight of the vibrator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com