Stainless steel bellows pipeline system for indoor gas

A pipeline system and internal gas technology, applied in pipeline systems, pipes/pipe joints/fittings, threaded connections, etc., to achieve the effects of preventing leakage, improving detection safety, and ensuring gas safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

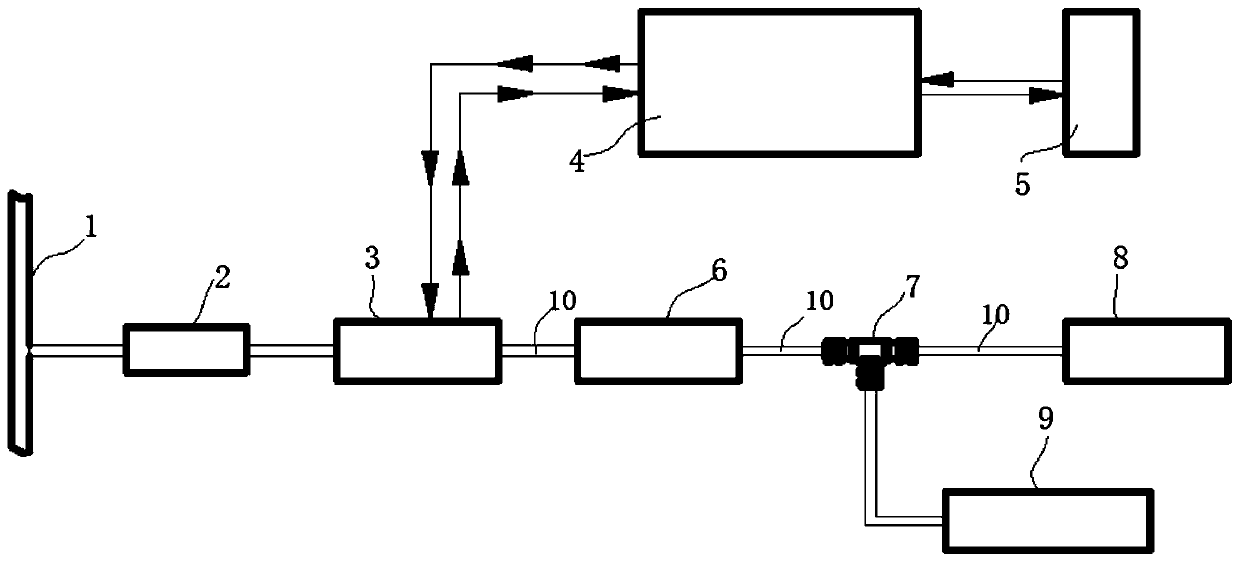

[0048] Such as Figure 1-Figure 10 As shown, the stainless steel corrugated pipe pipeline system for indoor gas in this embodiment includes the gas inlet pipe 1, the household main valve 2 and the gas control box 3 connected in sequence, and the gas control box 3 communicates with the data via wired or wireless means. The platform server 4 is connected to the signal, the data platform server 4 is connected to the processing terminal 5, the gas control box 3 is connected to the gas meter 6, and then connected to the household pipeline that needs to use gas through the connection valve 7, such as a gas stove 8 and a water heater 9 etc. for gas use; between the gas control box 3 and the gas meter 6, between the gas meter 6 and the household pipes that need to use gas, all are connected by bellows 10. In this embodiment, the corrugated pipe 10 is coated with a sensing fiber optic film, and a vibration sensor is also provided on the outside of the corrugated pipe 10; the processing...

Embodiment 2

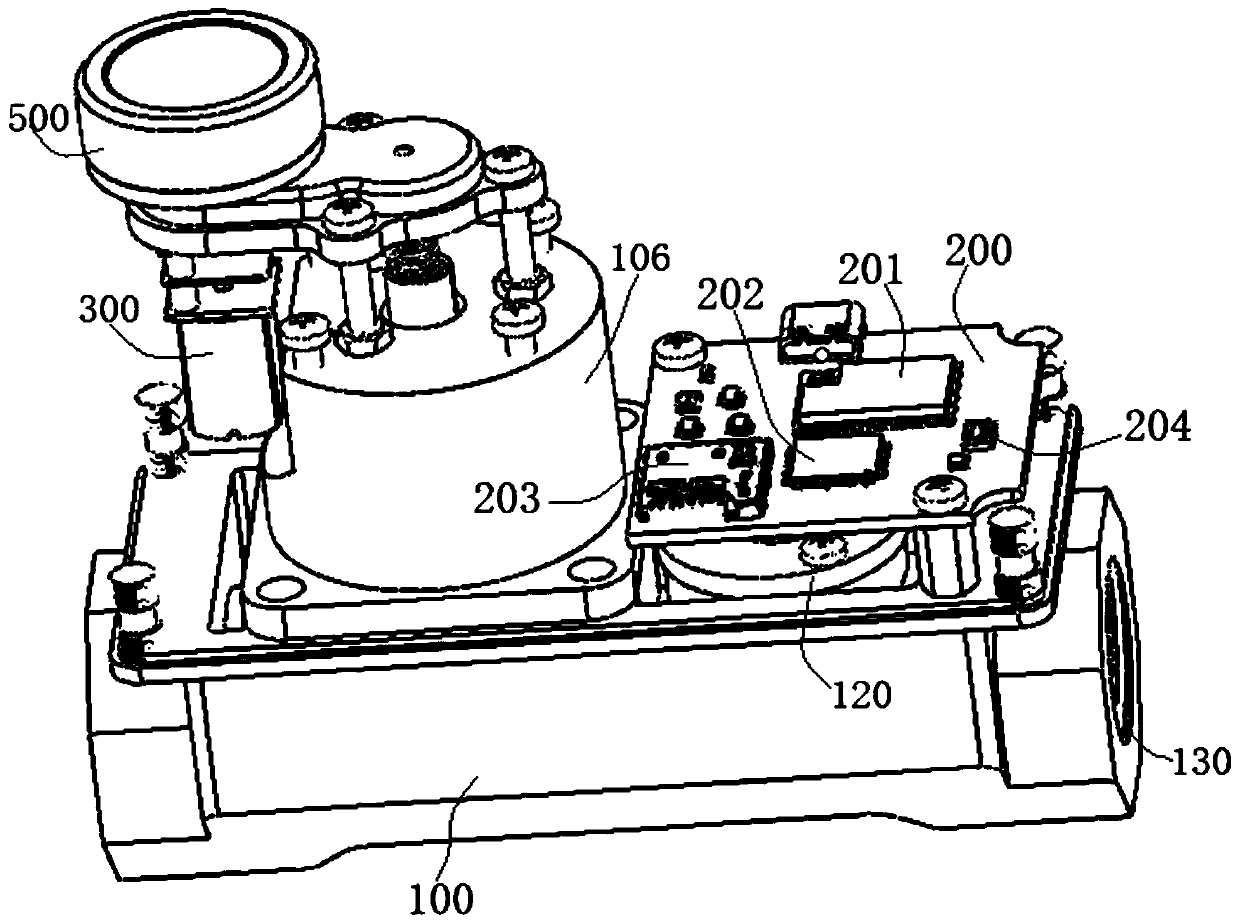

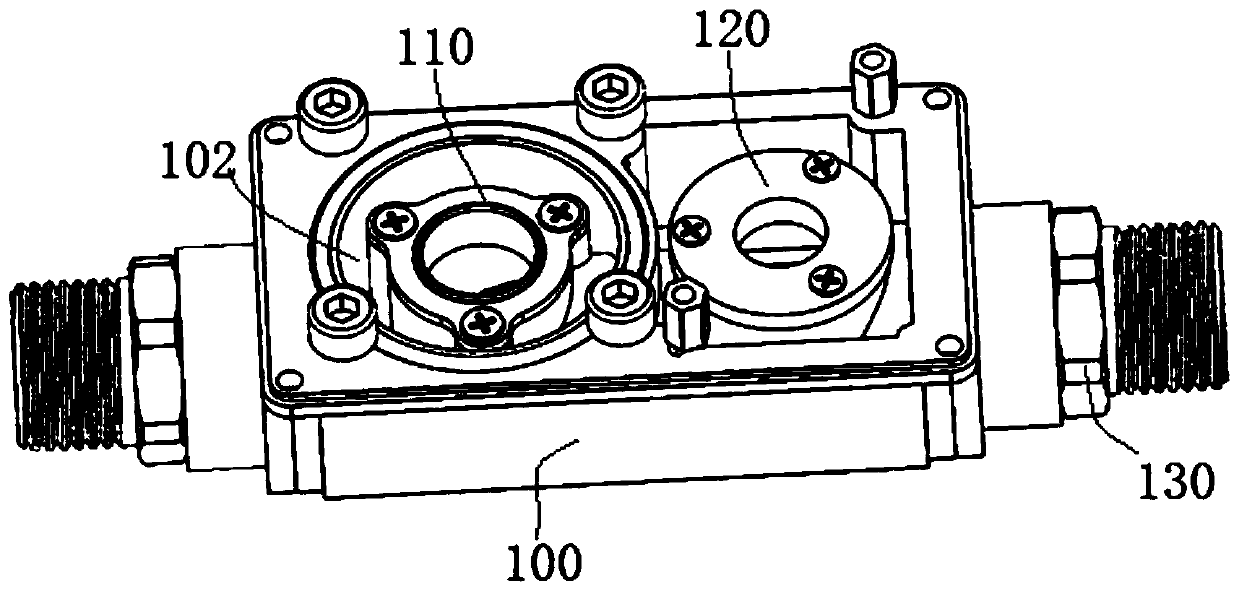

[0053] The stainless steel corrugated pipe pipeline system for indoor gas in this embodiment is basically the same as in Embodiment 1, further, as image 3 and Figure 4 As shown, in this embodiment, the valve body 100 is provided with a main flow cavity 101 for gas circulation, but the main flow cavity 101 located on the front and rear sides of the sealing interface is not directly connected, but the main flow cavity 101 is opened in the front and rear respectively, and the sealing An inner sealing cylinder 103 is arranged in the interface, and the inner sealing cylinder 103 and the front end of the valve body 100 (such as Figure 4 The gap between the main flow chambers 101 on the left side of the orientation) is the outer flow chamber 102, and the inner seal cylinder 103 is provided with an inner flow chamber 104, which is connected to the rear end of the valve body 100 (such as Figure 4 The main flow cavity 101 on the right side of the orientation) is connected to each o...

Embodiment 3

[0057] The stainless steel bellows pipeline system for indoor gas in this embodiment is basically the same as the above embodiment, further, as Figure 8As shown, the double-cavity sealing ring 400 in this embodiment includes an inner ring body 410 for pressing and sealing the inner circulation chamber 104, and an outer ring body with an inverted U-shaped cross section is arranged around the outer side of the inner ring body 410 upwards and circumferentially. 420, the outer edge of the outer ring body 420 is also provided with an outward extension section, the extension section is embedded in the inner side of the end cover cover 106, and the bottom of the extension section is provided with a circle of lower convex section 421, and the lower convex section 421 is embedded in the valve body below 100; the extension section is also provided with an inner convex section 422 at the contact position of the U-shaped opening, which is an arc-shaped smooth transition structure. Specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com