Efficient noise reduction exhaust pipe

An exhaust pipe and noise technology, applied in the field of high-efficiency noise-reducing exhaust pipes, can solve the problems of a small number of thin-walled inner liner, obstructing airflow flow, and limited noise reduction effect, so as to increase the movement stroke and slow down the noise transmission. time, the effect of prolonging the reflection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

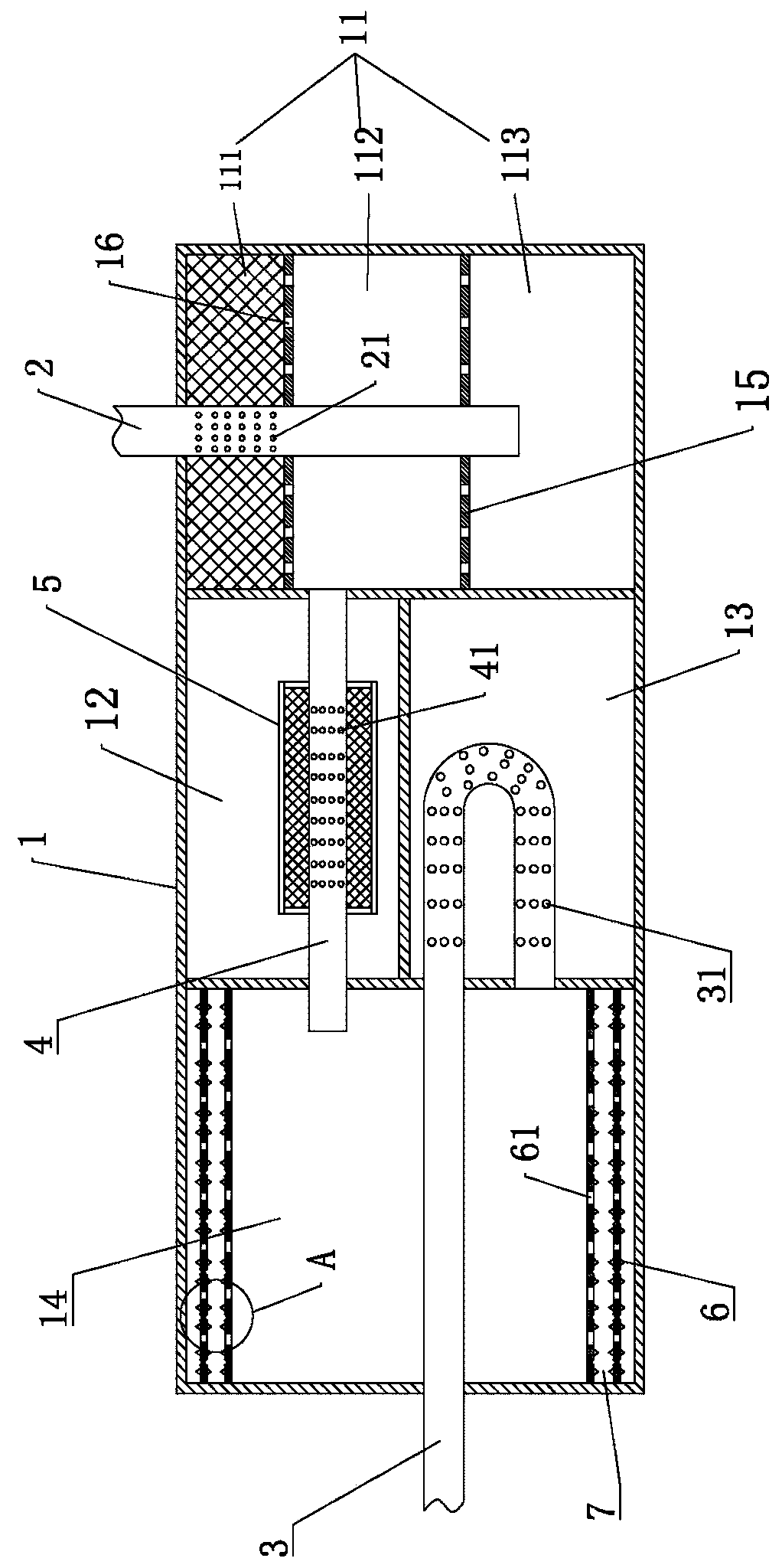

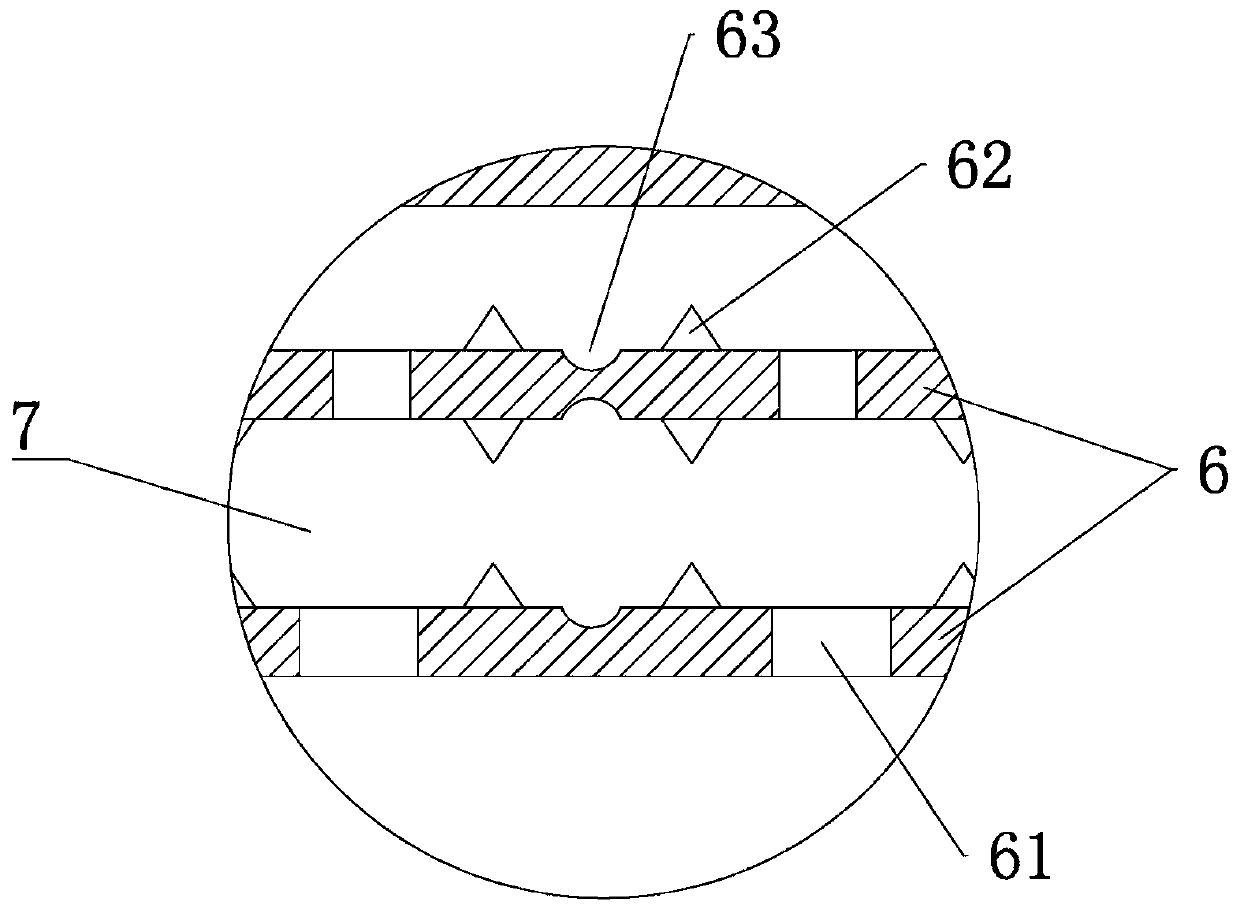

[0028] Embodiment 1: as figure 1 with figure 2 As shown, a high-efficiency noise-reducing exhaust pipe includes a cylinder body 1, an air intake pipe 2, an air outlet pipe 3 and a muffler pipe 4, and the cylinder body 1 is provided with an expansion chamber 11, a first resonance chamber 12, and a second resonance chamber 13 and the third resonant cavity 14, the expansion cavity 11 and the third resonant cavity 14 are located at both ends of the cylinder 1, and the first resonant cavity 12 and the second resonant cavity 13 are located in the middle of the cylinder 1.

[0029] The inlet pipe 2 communicates with the expansion chamber 11, the air outlet pipe 3 communicates with the third resonance chamber 14, the silencer pipe 4 is arranged in the first resonance chamber 12, and its two ends communicate with the expansion chamber 11 and the third resonance chamber 14 respectively, the silencer pipe 4 is provided with a first outlet hole 41 through which the muffler pipe 4 commun...

Embodiment 2

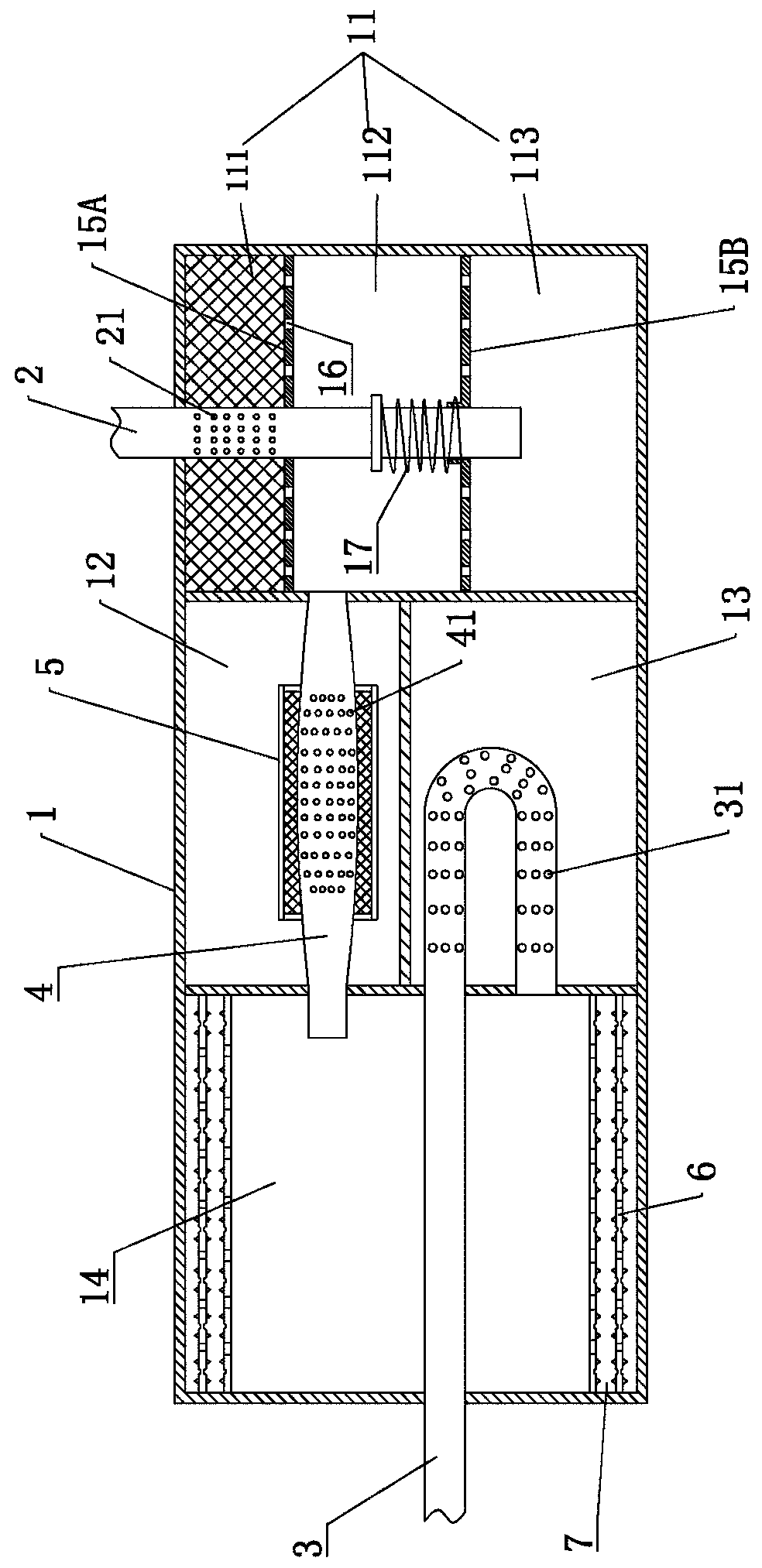

[0035] Embodiment 2: as image 3 As shown, the difference from Embodiment 1 is that the inner diameter of the muffler pipe 4 gradually increases from both ends to the middle, forming a drum-shaped structure.

[0036] The partition 15 is divided into a fixed partition 15A and a floating partition 15B. The fixed partition 15A is located between the first expansion chamber 111 and the second expansion chamber 112 and is fixed in the expansion chamber 11, and the floating partition 15B is located in the second expansion chamber. Between 112 and the third expansion chamber 113, the floating partition 15B is set on the intake pipe 2, and the second expansion chamber 112 is provided with an elastic reset member 17 that pushes the floating partition 15B to move away from the partition 15, elastically resets Part 17 is a spring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com