A flocculant-producing strain and its application in shrimp biofloc culture and dye decolorization

A technology of flocculant and bacteria production, applied in biochemical equipment and methods, applications, microorganisms, etc., can solve the problems of nutrient loss, increased incidence of shrimp, and surrounding environmental pollution, etc., and achieve high cellulase and xylan Enzyme activity, broad application prospects, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

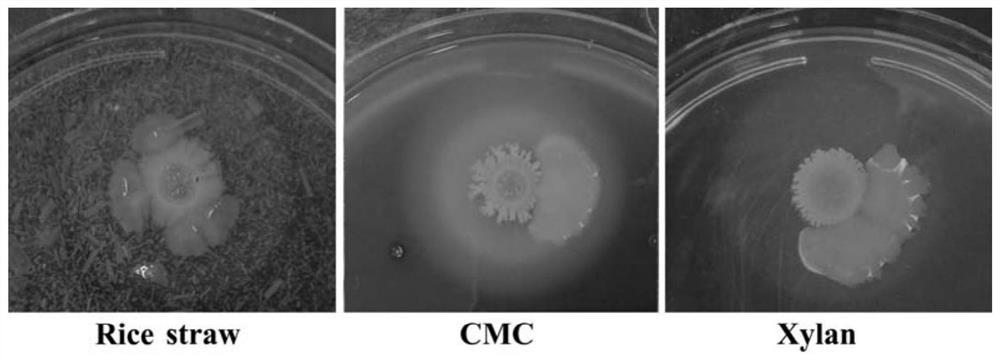

[0028] 1. Screening of flocculant-producing bacteria

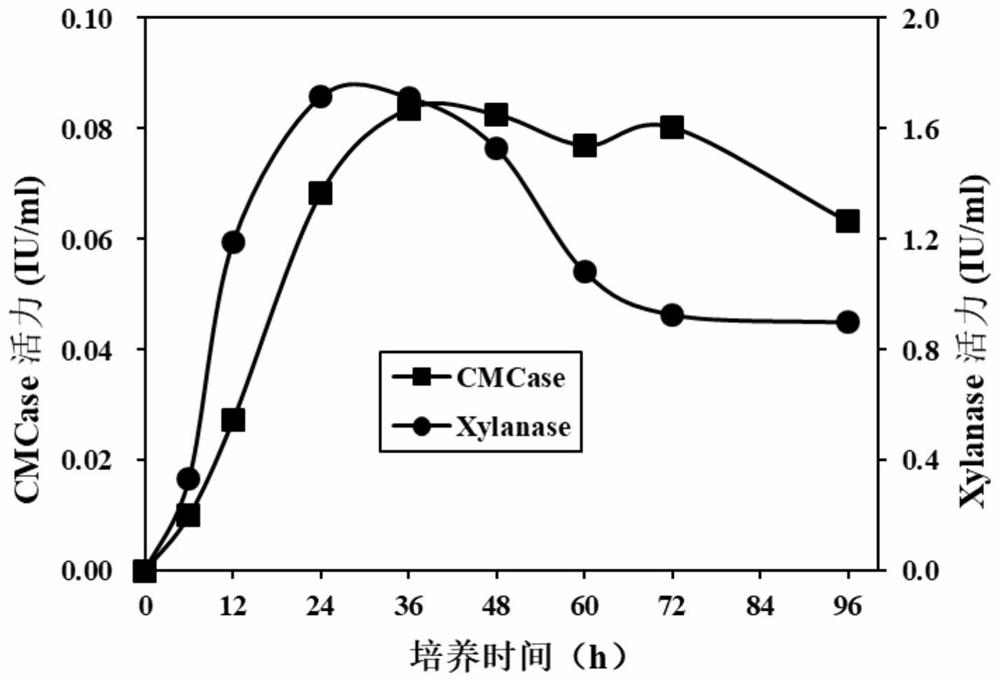

[0029] Take 5.0 g of biofloc from the Ninghai shrimp biofloc culture pond, resuspend in 50 ml of sterile PBS buffer, boil for 2 minutes, place on a constant temperature shaker at 30±2°C, and incubate at 180-220 rpm for 30 minutes. Then use the standard dilution plate coating method to spread on 1 / 2 of the 2216E solid medium, and culture it upside down in a constant temperature incubator at 30±2°C for 2-4 days. Pick a single colony and number it according to the shape and color of the colony. The picked single colonies were purified by drawing again, placed in 1 / 2 of the 2216E liquid medium, and cultured in a constant temperature shaker at 30±2°C, 180~220 rpm for 2~4 days, and the fermented liquid was collected and centrifuged at 12000g for 3 minutes Finally, the flocculation efficiency of the supernatant was measured by kaolin suspension, and the strain NBU10 with higher flocculation efficiency was selected for subsequent ...

Embodiment 2

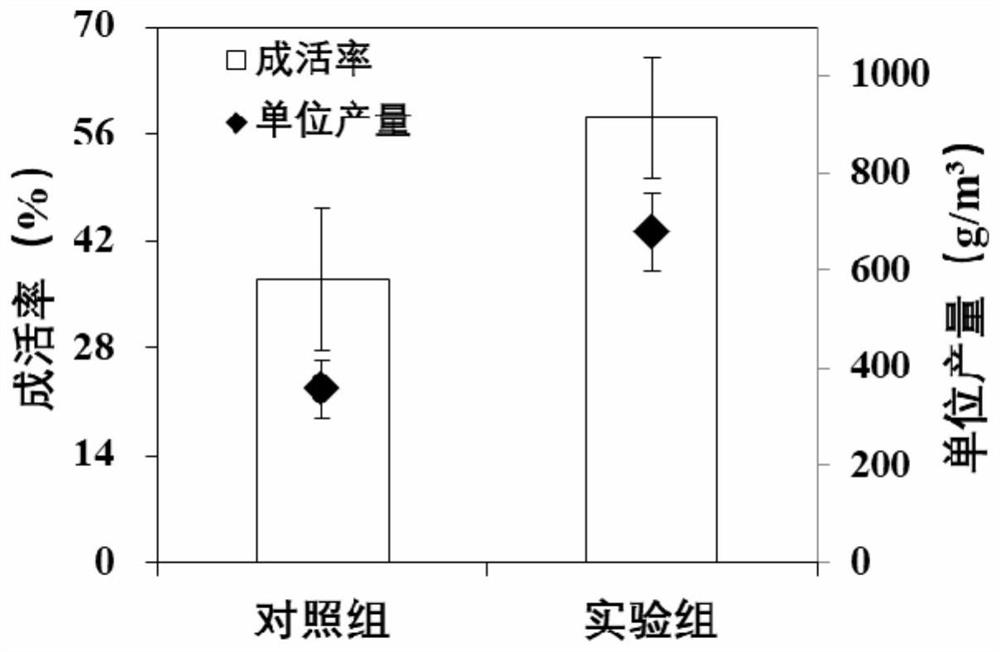

[0046] Utilize the bacterial strain that above-mentioned embodiment 1 obtains is applied to shrimp biofloc culture pattern

[0047] This experiment was completed in the Xianxiang breeding base in Ningbo City, Zhejiang Province. A total of 10 600 L (diameter 1 m, height 0.8 m) Litopenaeus vannamei breeding ecological experiment barrels were set up, of which 5 barrels were used as controls and 5 were used as wild animals. Xanthomonas napus NBU10 addition group. The shrimp seedlings were put in uniformly, about 200 seedlings were placed in each experimental bucket, and the experiment was formally started 2 days after the seedlings were released. The strain addition method is: Xanthomonas campestris NBU10 is cultured with 2216E medium until the bacterial liquid OD 600 When the absorbance value was about 1.0, 1 L of bacterial liquid and 500 g of rice straw powder were added to the addition group, and the control group was replaced by sterile medium. Feed 3 times a day (7:00, 12:0...

Embodiment 3

[0049] Fermentation Broth Preparation with Flocculation Activity and Its Application in Dye Removal

[0050] Inoculate the strain with the preservation number CGMCC No.16936 into the seed culture solution for seed culture, then inoculate the seed solution into the fermentation culture solution containing 0.25-1.0 wt% rice straw for fermentation and culture; place the fermentation solution at 4°C Overnight, carefully remove the precipitate, and the supernatant is the liquid flocculant with flocculation.

[0051] Take 50 mL of 50 mg / L Coomassie Brilliant Blue dye, add 0.5, 1.0, 2.0 and 3.0 mL of the above-mentioned liquid flocculants, and then add 1 mL of 10 g / L calcium chloride solution, and stir rapidly for 1 min. After stirring slowly for 30 s, let stand at room temperature for 30 min, take the supernatant and measure its absorbance value B at 563 nm. With the addition of 0.5, 1.0, 2.0 and 3 mL of distilled water as controls, the absorbance value A at 563 nm was measured, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com