A Rapid Prototyping Method for Continuous Fiber Reinforced Plastic Automobile Parts

A continuous fiber and auto parts technology, applied in the field of rapid prototyping of continuous fiber reinforced plastic auto parts, can solve the problems of demanding resin viscosity and wettability, unsatisfactory appearance and performance, etc. Stomatal defects, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

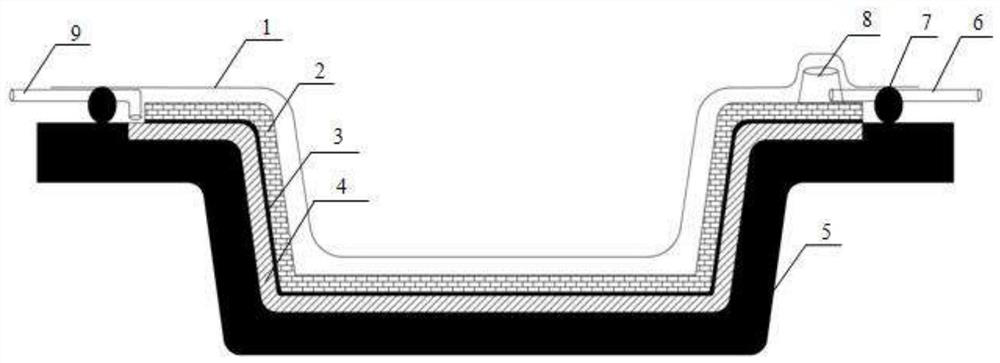

[0033] refer to figure 1 , a rapid prototyping method for continuous fiber-reinforced plastic automotive parts, comprising the steps of:

[0034] S1: Forming a silicone base mold 5: Forming a silicone base mold using a silicone resin thermosetting molding process. Specifically, coat the surface of the hard mold cavity with a release agent, heat it to a certain temperature, mix and inject the silicone resin and curing agent In the cavity of the hard mold, open the mold after curing is complete, take out the silicone bottom mold, and the thickness of the prepared silicone bottom mold is 5mm;

[0035] S2: Lay a continuous fiber layer in the cavity of the silicone bottom model 4: Wipe the surface of the silicone bottom model cavity clean, apply a release agent, and tightly fit the continuous fiber layer in the silicone bottom model cavity;

[0036] S3: Infiltrate the continuous fiber layer with resin under vacuum and low temperature conditions: Lay a covering layer on the surface...

Embodiment 2

[0043] refer to figure 1 , a rapid prototyping method for continuous fiber-reinforced plastic automotive parts, comprising the steps of:

[0044] S1: Forming a silicone base mold 5: Forming a silicone base mold using a silicone resin thermosetting molding process. Specifically, the surface of the hard mold cavity is coated with a release agent, heated to a certain temperature, and the silicone resin and curing agent are prepared and injected. In the cavity of the hard mold, open the mold after curing is complete, take out the silicone bottom mold, and the thickness of the prepared silicone bottom mold is 8mm;

[0045] S2: Laying a continuous fiber layer in the cavity of the silicone bottom model 4: Wipe the surface of the silicone bottom model cavity clean, apply a release agent, and tightly fit the continuous fiber layer in the silicone bottom model cavity;

[0046]S3: Infiltrate the continuous fiber layer with resin under vacuum and low temperature conditions: Lay a coverin...

Embodiment 3

[0053] refer to figure 1 , a rapid prototyping method for continuous fiber-reinforced plastic automotive parts, comprising the steps of:

[0054] S1: Forming a silicone base mold 5: Forming a silicone base mold using a silicone resin thermosetting molding process. Specifically, coat the surface of the hard mold cavity with a release agent, heat it to a certain temperature, mix and inject the silicone resin and curing agent In the cavity of the hard mold, open the mold after curing is complete, take out the silicone bottom mold, and the thickness of the prepared silicone bottom mold is 10mm;

[0055] S2: Laying a continuous fiber layer in the cavity of the silicone bottom model 4: Wipe the surface of the silicone bottom model cavity clean, apply a release agent, and tightly fit the continuous fiber layer in the silicone bottom model cavity;

[0056] S3: Infiltrate the continuous fiber layer with resin under vacuum and low temperature conditions: Lay a covering layer on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com